Laser Marking Systems / Laser Markers

Laser Ablation

Laser ablation is the process of heating a surface to its ablation point so the top layer vaporizes. Lasers achieve this by using a short pulse laser with high power, which ensures that only the top layer is targeted and there is no effect on the substrate. Industrial laser ablation is a non-damaging and resourceful marking and surface removal process that can be used for many applications.

Five Ways to Use Laser Ablation

1. Paint Removal

Removing paint with laser ablation is used for design changes, revealing underlayer lights/paint, inspection, and maintenance.

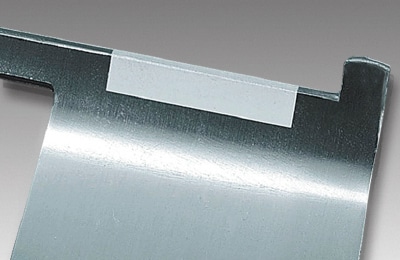

2. Coating Removal

Laser ablation to remove coatings, also known as laser cleaning, is the process of deburring or ablating a coating to expose a section of the product or material that should not be coated.

3. Oxidation/Rust Removal

Laser ablation removes rust or oxidation so that a part or component can return to its original properties without unwanted changes from corrosion like increased friction, change in surface color, lower magnetic attraction, and weakening of the structure.

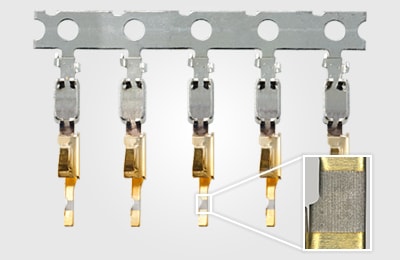

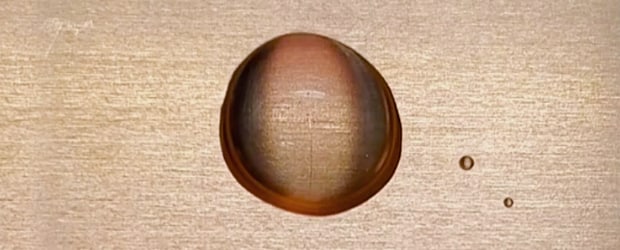

4. Texturing

Laser ablation can be used to remove micrometers of material from a product in desired patterns to increase adherence, wettability, electrical conductivity, thermal conductivity. This process is also referred to as laser texturing.

Unprocessed

Processed

Unprocessed

Processed

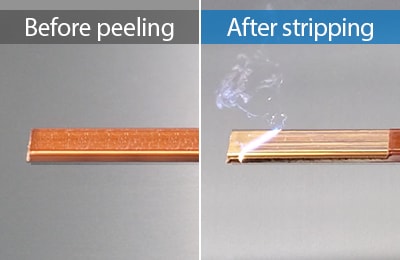

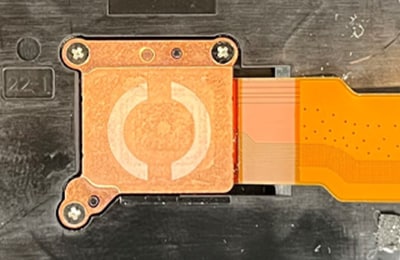

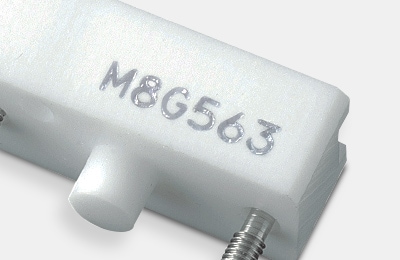

5. Engraving

Using laser ablation to engrave utilizes laser technology to ablate carved-out designs for logos, 2D codes, or part numbers.

Laser Ablation Equipment

KEYENCE offers a fiber, hybrid, and UV laser for laser ablation applications. The laser ablation equipment is built for high speed marking/ablation while minimizing heat stress onto the target. Here is some information about each:

3-Axis Fiber Laser Marker MD-F Series

The fiber laser marker is recognized for high speed and high powered processing, which makes it ideal for removing stubborn coatings and engraving deeply.

| Laser Ablation Services | Materials |

|---|---|

|

Laser Ablation Services

|

Materials

|

3-Axis Hybrid Laser MD-X Series

The MD-X Series combines a fiber laser and a YVO4 laser to create a hybrid laser. The hybrid laser is versatile with ablation capabilities and surface areas because of the high output but short pulse laser. This beam ablates with 2x the power of a conventional YVO4 laser with less heat stress.

3-Axis UV Laser MD-U Series

The MD-U uses an ablation process called “cold marking,” meaning there is no heat stress added to the target because the absorption rate is so high. Since there’s no heat stress, the MD-U laser specializes in ablating highly reflective, heat-sensitive materials with high ablation temperatures.

Laser Ablation System Software

KEYENCE’s laser ablation machines include software called Marking Builder (3 or Plus). This laser ablation software ensures ablation compatibility for any surface by using a built-in camera to analyze the target.

The software can use the built in camera to provide clarity on marking alignments with extreme ease, and no need for physical adjustments. It can adjust focal distances for 3D shapes or curved/angles targets. The software is also compatible with 3D CAD files for any unique geometries that are not your typical sphere, cylinder, or slope.

Finding Your Laser Ablation System

At KEYENCE, we specialize in laser technology. Our laser marking machines are versatile laser ablation machines with software that ensures uniformity and precision even on complex surfaces.

Whether you need to mark, texture, or remove a surface, KEYENCE’s lasers can help achieve your goals. Contact us today to find the best laser marking machine for your laser ablation needs.

Related Downloads

This booklet covers a wide range of laser processing techniques - such as cutting, drilling, and deep engraving - as well as welding and soldering that are unique to lasers.