Ink characteristics

- Q1. What types of ink are available?

- Q2. What sort of materials can be printed on?

- Q3. What are the components of the ink?

- Q4. Do printed characters fade?

- Q5. Is the ink water soluble?

- Q6. Is the ink subject to PRTR laws?

- Q7. Is the ink treated as a poisonous or deleterious substance?

- Q8. Approximately how many characters can be printed with a single ink cartridge?

- Q9. Does the ink have an expiration date?

- Q10. How do I store ink?

- Q11. What should I do when I get ink in my eyes?

- Q12. How do I dispose of ink waste?

Q1. What types of ink are available?

| MK-10 | Standard ink | This is a standard type of industrial ink that can be used for general purposes in a variety of industries. |

|---|---|---|

| MK-14 | MEK free ink | MEK is not included in the ink components, which reduces chemical odor and provides an alternative ink for compliance with certain safety standards. |

| MK-30 | Yellow ink | By using ink with yellow pigment, clear printing is possible on black workpieces. This enables highly visible printing on black-coated automotive parts and black resin-molded products. |

| MK-33 | White ink | Pigment-type ink for greatly improved maintenance. |

Q2. What sort of materials can be printed on?

Industrial-use inkjet printers can print on a wide variety of materials such as metals, resins, glass, packing films, cans, and PET bottles.

In order to print on products moving on production lines, quick-drying ink, which dries in approximately 1 second, is used.

This enables printing on materials other than just highly absorbent ones such as paper and cardboard. As such, these printers

are used in a wide range of applications in the food, medical, cosmetic, electrical and electronic component, transportation, and metal industries.

Material examples

Containers and packaging materials

- Porous materials

- Paper, roll paper, cardboard, paper bags, textiles, etc.

- Nonporous materials

- Glass, aluminum cans, PET bottles, wrapping film, pottery, ceramics, etc.

Building materials

Lumber, plaster boards, piping (polyvinyl chloride pipes), aluminum sashes, etc.

Electrical, electronic, mechanical, and automotive parts

Resin-molded products, molded products, metal-worked products, cast products, etc.

Surface shape examples

Curved, cylindrical, and rough surfaces

Batteries, LEDs, bottles, aluminum wheels

Spherical and elliptical surfaces

Golf balls, light bulbs, eggs, etc.

Q3. What are the components of the ink?

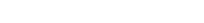

View the SDS (Safety Data Sheet) for each ink and solvent.

What is an SDS (Safety Data Sheet)?

This is a document that provides information regarding the characteristics and handling of chemical substances that may be hazardous. It is presented when transferring control to another user or when providing a user with a product that includes these chemical substances.

* These were previously referred to as MSDS (Material Safety Data Sheets). However, the name was unified to SDS, which is the abbreviation prescribed by the UN GHS (Globally Harmonized System of Classification and Labeling of Chemicals), in April 2012.

SDS (example)

SDS contents

- 01 Identification of the substance/mixture and of the company/undertaking

Product identifier as well as the name, address, and telephone number of the supplier of the SDS

- 02 Hazards identification

- 03 Composition/information on ingredients

Names of included designated chemical substances as well as classification and content by percentage of designated chemical substances (two significant digits)

- 04 First aid measures

- 05 Firefighting measures

- 06 Accidental release measures

- 07 Handling and storage

- 08 Exposure controls/personal protection

- 09 Physical and chemical properties

- 10 Stability and reactivity

- 11 Toxicological information

- 12 Ecological information

- 13 Disposal considerations

- 14 Transport information

- 15 Regulatory information

- 16 Other information

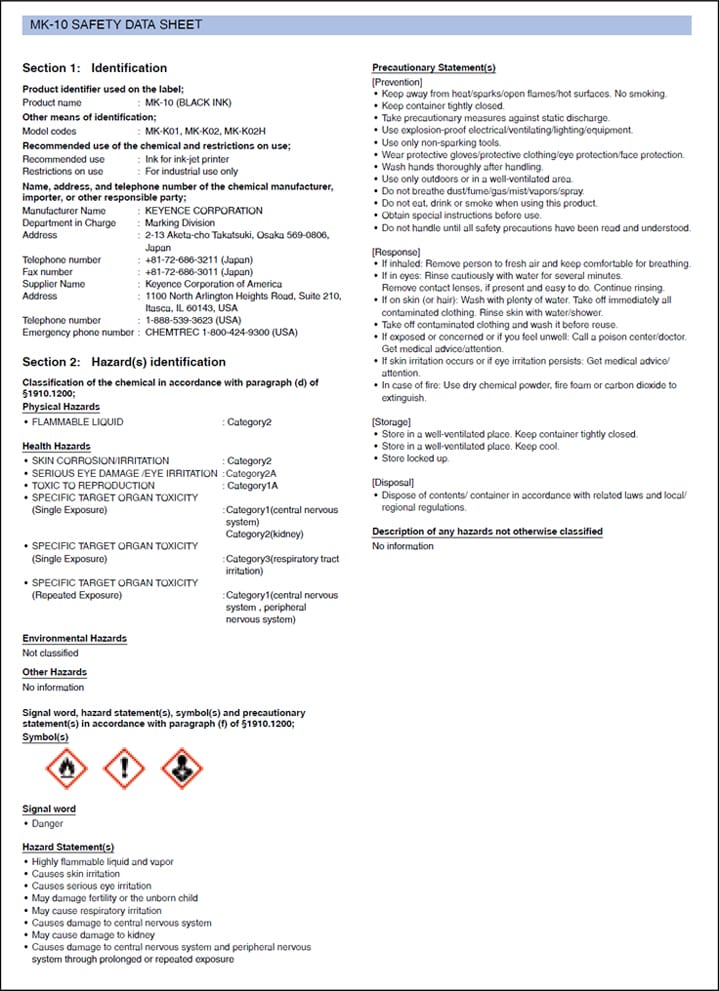

Q4. Do printed characters fade?

Inkjet printers can print on a variety of materials, but ink rubs off easily from some materials such as poly resins (PP and PE), glass, and rubber.

We have prepared a super-adhesive type of ink (MK-13) for materials to which the standard ink does not adhere well. By improving the binders, which are the adhesive components of this ink, we have improved its adhesive capability even for materials other than poly materials.

Materials that are easy to print on

| Material name | Inkjet printer | |

|---|---|---|

| Resin | PE (polyethylene) | Good |

| PC (polycarbonate) | Excellent | |

| PP (polypropylene) | Good | |

| POM (polyacetal) | Excellent | |

| PBT (polybutylene terephthalate) | Excellent | |

| PET (polyethylene terephthalate) | Excellent | |

| ABS (acrylonitrile butadiene styrene) | Excellent | |

| EP (epoxy) | Excellent | |

| PF (phenol) | Excellent | |

| UF (urea) | Acceptable | |

| PVC (vinyl chloride) | Excellent | |

| PA (polyamide) | Excellent | |

| SI (silicon) | Good | |

| Metal | Iron | Excellent |

| Aluminum | Excellent | |

| Nickel | Excellent | |

| Stainless steel | Excellent | |

| Copper | Excellent | |

| Gold | Excellent | |

| Other | Ceramic | Excellent |

| Wood | Excellent | |

| Paper | Excellent | |

| Glass | Good | |

| Rubber | Good |

Q5. Is the ink water soluble?

The MEK ink is not water soluble, but the MEK free ink is water soluble.

Differences between water-soluble and non-water-soluble ink

The risk of fire for water-soluble ink is half the risk for non-water-soluble ink.

| Non-water-soluble (MEK ink) |

Water-soluble (MEK free ink) |

|

|---|---|---|

| Specified quantity |

200L

|

400L

|

This is because particles with a small relative weight are difficult to dissolve in water. Particles with a low relative weight can then rise to the surface of the liquid, easily flowing out and spreading when water is used to put out a fire on this ink.

* The information shown above is an example of equally hazardous volumes of ink.

Q6. Is the ink subject to PRTR laws?

The ink is not subject to PRTR laws because, although it contains trivalent chrome alloy and toluene, which are type 1 designation chemical substances according to PRTR laws, they make up less than 1% of the total mass of the product (ink).

What are PRTR laws?

(Pollutant Release and Transfer Register)

These are laws related to the necessity of understanding, collecting, and making public data on harmful chemical substances. This data includes the origins of chemical substances, the amount of these substances that have been released into the environment, and whether they have been carried out of industrial facilities as components of waste material.

Q7. Is the ink treated as a poisonous or deleterious substance?

MEK (methyl ethyl ketone) is specified as a deleterious substance, but this is not an active ingredient, so the ink is not treated as a deleterious or poisonous substance under the same law.

* Active ingredient refers to substances that are only composed of MEK, so MEK is judged to not be an active ingredient for mixtures such as ink and solvent.

Q8.Approximately how many characters can be printed with a single ink cartridge?

Approximately how many characters can be printed with a single ink cartridge?

Typical example

* The number of characters explained here refers to the case when the character size is 7 × 5 dots (average number of drops used per character: 15).

800 mL cartridge

- MK-G1000 (standard model): Approx. 71 million characters

- MK-G1100 (small character model): Approx. 200 million characters

450 mL cartridge

- MK-G1000 (standard model): Approx. 40 million characters

- MK-G1100 (small character model): Approx. 110 million characters

Ink example

| Ink model | Type | Volume (cc) | Product (set) model | Number of cartridges |

|---|---|---|---|---|

| MK-10 (black ink) |

Standard | 800 | MK-K01 | 1 |

| 800 | MK-K02 | 2 | ||

| 450 | MK-K02H | 2 |

| Ink model | ||

|---|---|---|

| MK-10 (black ink) | ||

| Type | ||

| Standard | ||

| Volume (cc) | Product (set) model | Number of cartridges |

| 800 | MK-K01 | 1 |

| 800 | MK-K02 | 2 |

| 450 | MK-K02H | 2 |

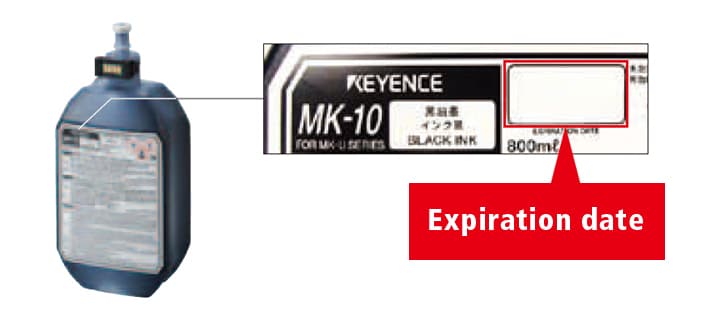

Q9. Does the ink have an expiration date?

Useful life

The expiration date of the ink and solvent is 12 months after the cartridges are inserted into the inkjet printer.

If you continue to use old ink that has passed its expiration date, the printing quality may deteriorate and irregular maintenance may be necessary.

Equipped with an IC chip

Each cartridge is equipped with an IC chip. If the expiration date of the ink or solvent (written on the label) passes, the chip detects this and notifies the user of the need to replace the cartridge with a new one.

Q10. How do I store ink?

Please store ink under the following conditions.

Recommended storage conditions

- Store in a cool, well-ventilated place, away from exposure to direct sunlight and rain.

- Keep away from fire and other heat sources.

- Seal the container for storage after opening.

- Do not place any substances that break down and produce oxygen nearby.

- Store under conditions in compliance with relevant laws and regulations.

- Keep in a locked location to prevent theft.

- Use KEYENCE’s bottle to store the ink.

* The ink and solvent are volatile, flammable substances. Follow the local rules for storage and handling.

| Non water-soluble (MEK ink) | Water-soluble (MEK-free ink) | |

|---|---|---|

| No notification required |

Less than 40 L

|

Less than 80 L

|

| Notification to a fire chief or fire station chief is required |

40 L or more

|

80 L or more

|

| Stored and handled in compliance with Fire Service Act requirements |

200 L or more

|

400 L or more

|

* Check with a representative at the local Labor Standards Inspection Office for final judgment.

Storage amount and notification

Please store ink under the following conditions.

- Notification is not required for an amount less than 1/5 of the statutory quantity, but manufacturers still have the obligation to store ink in compliance with the Fire Service Act.

- Notification to the fire chief or fire station chief is required for storing an amount 1/5 of the statutory quantity or more, but within the statutory quantity.

- Storing or handling an amount over the statutory quantity is regulated by the Fire Service Act and other relevant laws. It is forbidden to store or handle ink and solvent in places other than designated storage/handling facilities.

Statutory quantity

Storing or handling of hazardous materials in an amount over the statutory quantity is regulated by the Fire Service Act and other relevant laws. It is forbidden to store or handle such materials in places other than designated manufacturing/storage/handling facilities.

Q11. What should I do when I get ink in my eyes?

Wash your eyes immediately with cold or lukewarm water and consult a physician.

| Warning |

|

|---|---|

| Caution |

|

Q12. How do I dispose of ink waste?

Ink waste falls under special controlled industrial waste.

Waste Management and Public Cleansing Act (Disposal Act)

Ink, solvent, and ink waste fall under special controlled industrial waste (waste fluid).

Please use the service of a specialized industrial waste disposal business operator certified by the prefectural governor.

![Learn the Basics of Continuous Inkjet Printers [CIJ Central]](/Images/ss_products_inkjet_header_title_1785688.gif)

![Inkjet Printer Tech Guide [Basic Knowledge Edition]](/img/asset/AS_114378_L.jpg)