Laser Marking Systems / Laser Markers

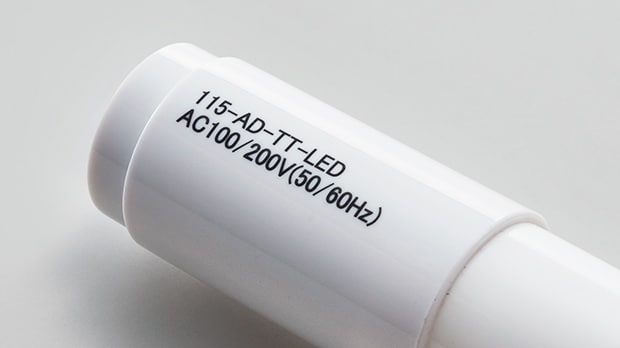

Laser Marking on Plastic

Direct Part Laser Marking on Plastic Parts

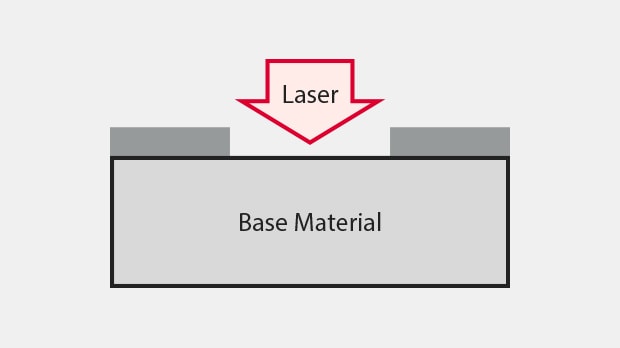

Laser marking is a reliable and cost-effective technique often used to mark plastic parts. By precisely laser etching plastic surfaces, this equipment produces permanent, high-quality marks. These markings also cause minimal distortion and are resistant to chemicals, abrasion, and extreme temperatures. Common plastics laser-marked include ABS, epoxy, and PET. When laser marking plastic products, the laser light does not penetrate the material. Instead, it chemically or thermally changes its surface according to the laser power intensity within the beam of light.

Laser markings may typically be seen in applications such as brand logos engraved on various appliances and portable electronics, part numbers printed on automotive parts such as brake calipers, or serial numbers etched onto medical tools. As a valuable tool for personalization and customization, laser marking plastic has proven to be a valuable option for manufacturers across numerous industries.

Types of Laser Marking Machines for Plastic

Laser marking plastic differs from other materials because of plastic’s heat properties. When plastic is exposed to heat, it traps it. By trapping the heat, it can cause distortions or swelling from heat sensitivity. Because of this, laser marking plastic requires a laser marking machine that applies minimal heat. This can either be a UV or a hybrid laser marking machine.

UV Laser Marker

UV lasers are used for laser marking plastic because they mark with a process called “cold marking.” Because they operate at a much shorter wavelength than standard lasers (355 nm vs 1064 nm), they are able to process the surface of the material without heat. This provides a higher level of contrast without any damage to the material.

Hybrid Laser Marker

Hybrid laser marking machines use a combination of a YVO4 laser and a fiber laser for laser marking plastic. Together, these lasers make a 1064 nm wavelength with a short pulse and 200kW peak power. The drastically higher peak power allows for high quality marking without the thermal damage that often results from a standard fiber laser.

CO2 Laser Marker

CO2 laser markers use a high level of heat to “melt” the surface of materials, creating a raised or etched mark. This method does not rely on color contrast but provides durable, permanent marking on plastic in addition to wood, ceramic, and other materials. CO2 laser marking is commonly used for product branding and identification across a range of industries.

Dark Marking on Plastic

Dark marking on plastic is created by using laser radiation on typically lighter-colored plastics to create beautiful, vivid contrasting markings. By using this technique, damage from marking the target is minimized.

White Marking on Plastic

White marking on plastic is created by using laser radiation on typically darker-colored plastics to create equally attractive and contrasted markings. Likewise, damage from marking the target is minimized using this technique.

White marking ABS connector

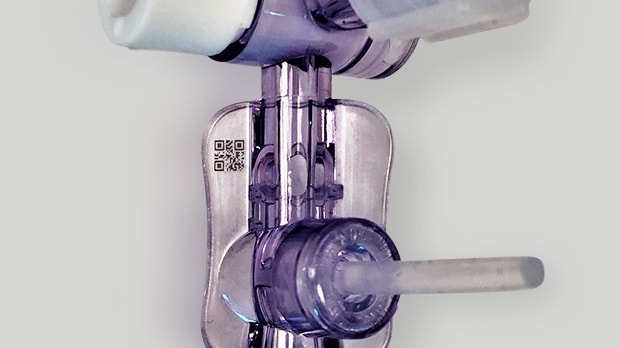

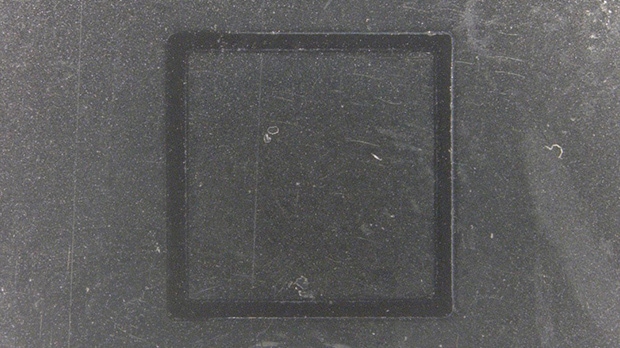

Transparent Plastic Laser Marking

Transparent marking on plastic is created by using laser radiation on transparent plastics that typically have a slight colorization to create excellent contrasting markings. Highly dependent on the material composition of these transparent parts, the markings can become darker or lighter once they have reacted with the absorbed laser marking beam.

Plastic Laser Processing

Plastic laser processing can consist of many different forms, such as cutting, peeling, drilling, or cleaning. Some of these processes are used to provide better quality, while others can eliminate the need for chemicals or other solutions.

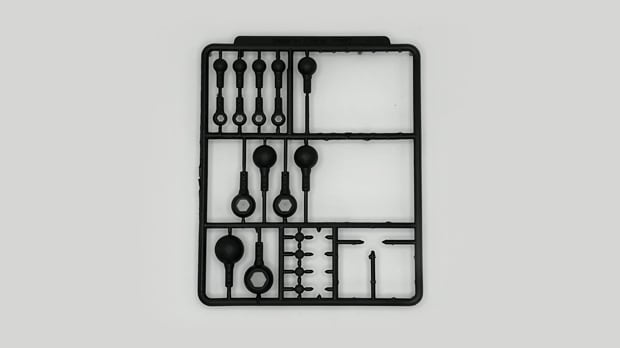

Plastic gate cutting

Major Types of Laser Marking on Plastic

When it comes to laser marking plastic, there are a few main types of processes to achieve the desired results.

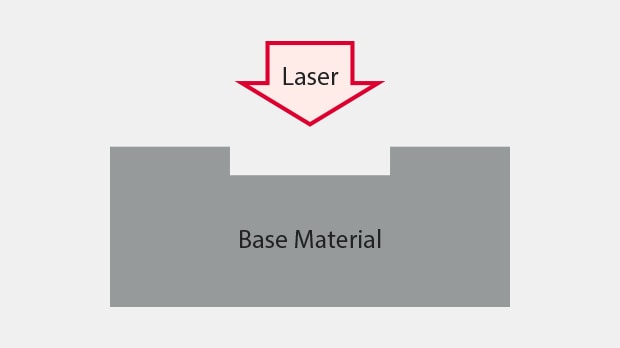

Paint Peeling

Peel the paint or printing on the target surface to bring out the contrast with the color of the base material.

(Example) Automobile instrument panel switch

Paint peeling has risen in popularity due to its simplicity and convenience. For one, conventional methods (like printing and stamping) require full plate changeovers when a design change occurs. With a laser marker, you can adjust layouts by simply changing the program. For example, in the panel switch example above, if the manufacturer wanted to print on top of the panel switch, it would require custom printing plates. Laser marking makes this task easy as it simply peels the paint off, saving both time and money.

Surface Layer Peeling

Remove/engrave the surface layer with a laser.

(Example) Half cut

Surface layer peeling helps expose the hidden materials beneath our everyday layers, like paint, aluminite, and more. By removing these coatings with this process, a grounding point is created to better access what lies underneath. This enables new possibilities for creativity or problem-solving when it comes to marking on plastic surfaces.

A laser marker can be used to easily process a cutting section. Physical cutters are conventionally used in these scenarios but are difficult to adjust and time-consuming to change. Moreover, physical blades must be replaced often (incurring hard costs), and there's a risk that the blade will come loose and get left in the product.

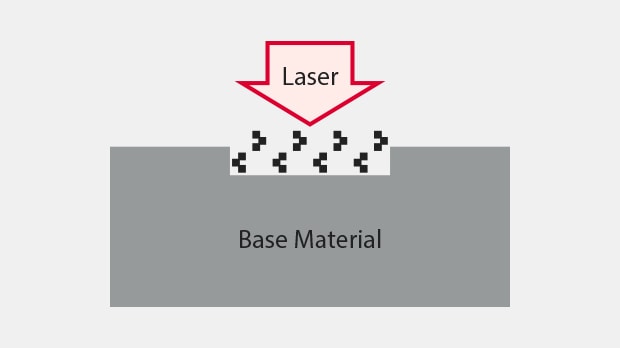

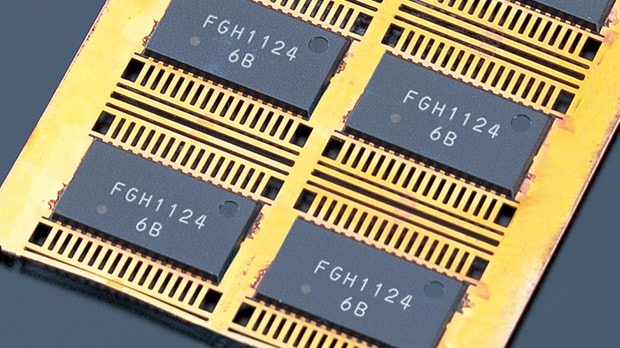

Color Development

Irradiate a plastic target with a laser to develop a color in the target itself.

(Example) Wide-area marking on LSI

Color development is used to create beautiful, vivid colors on plastic targets without causing any damage or engraving the material. This common technique allows for personalized customization with creative and unique designs. Using laser radiation to develop a color instead of engraving the plastic minimizes damage from marking the target.

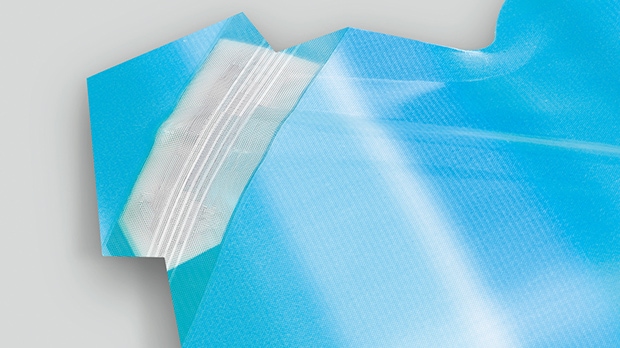

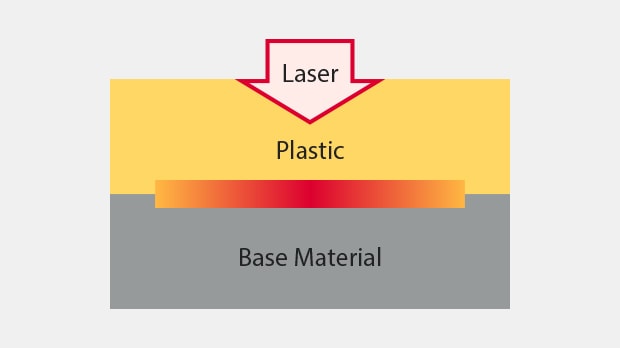

Welding

Use the heat of laser radiation to weld and join plastic parts.

(Example) Welding of transparent plastic and colored plastic

Laser radiation welding offers a reliable and efficient way to join plastic parts, with the added benefit of no vibration, which could negatively affect the product's quality. Without making contact during the process, delicate products remain untouched, eliminating any potential imperfections or damages that may occur due to burrs.

Whatever techniques are chosen, laser marking adds clarity, precision, and visibility, making it an ideal choice for long-term results in plastic applications.

Future Trends in Plastic Laser Marking

In the past, manufacturers used printing or labeling for marking on plastic for traceability marks, barcodes, or other identifications. However, printing and labeling have adverse effects like the use of consumables and possible contamination when the mark wears off.

Now that laser marking plastic is advancing and moving faster than printing or labeling machines, machine innovations are sprouting up. Moving forward, laser marking machines are adding data storage and additional software for marking. Plastic laser marking is also taking on smaller marking shapes and sizes because of beam precision.

Related Downloads