Dimensional Measurement of Distribution Board, Switchboard, Control Panel, and Cubicle Enclosures

Distribution boards, switchboards, control panels, and cubicles are vital pieces of equipment in supplying power to factories and large-scale facilities. They are installed outdoors or inside factories, so their enclosures require high dimensional accuracy in addition to high dustproofing, weather resistance, and strength. However, these enclosures are long and their panels have wide areas, causing the time and effort required for measurement to directly affect the delivery date. Therefore, the dimensional measurement needs to be performed in as little time as possible.

This section explains the measurement points of the enclosures of distribution boards, switchboards, control panels, and cubicles (which require short delivery times and improved quality) as well as the problems related to these measurements. It also introduces example solutions to measurement problems with our latest coordinate measuring machine (CMM), a device that is vital to optimizing dimensional measurements of enclosures.

- What Are Distribution Boards, Switchboards, Control Panels, and Cubicles?

- Distribution Board, Switchboard, Control Panel, and Cubicle Enclosure Characteristics

- Necessity of Dimensional Measurement of Distribution Board, Switchboard, Control Panel, and Cubicle Enclosures

- Distribution Board, Switchboard, Control Panel, and Cubicle Enclosure Dimensional Measurement Points

- Problems of Dimensional Measurement of Distribution Board, Switchboard, Control Panel, and Cubicle Enclosures and Their Solutions

- Optimization of Dimensional Measurement of Distribution Board, Switchboard, Control Panel, and Cubicle Enclosures

What Are Distribution Boards, Switchboards, Control Panels, and Cubicles?

Distribution boards, switchboards, control panels, and cubicles are devices used to receive high-voltage electric power transmitted from a power company. Among them, devices that handle electric power at or above a certain voltage are also referred to as non-utility electric facilities.

Among them, cubicles are also referred to as cubicle-type, high-voltage power receiving equipment. They refer to devices housing machines that convert the high-voltage electricity sent from a power station and through a transformer substation to a voltage that can be used within the facility. They comprise multiple machines such as transformers, disconnecting switches, and protective devices and also house devices such as distribution boards, switchboards, and control panels. Housing in one enclosure various machines related to voltage transformation and control not only reduces construction costs and saves space but also allows safety to be maintained.

Distribution Board, Switchboard, Control Panel, and Cubicle Enclosure Characteristics

Materials and structures that mainly take into account the usage environment are used in the enclosures of distribution boards, switchboards, control panels, and cubicles.

Enclosure materials

The main materials used in enclosures are iron (steel plate), stainless steel, aluminum, and resin. These are selectively used according to the operating environment. For example, if an enclosure is to be installed in a location where corrosion may occur due to salt damage (such as locations close to oceans), stainless steel or iron (steel plate) that has been plated or otherwise subjected to rustproofing is used. Also, aluminum or resin is used for the material if lightweight enclosures are required, such as in installation locations with weight restrictions.

Enclosure structures

Enclosure structures vary depending on the installation location. Enclosures used indoors undergo dustproofing to prevent dust and fine particles from entering inside the enclosure. Enclosures installed outdoors are affected by high and low temperatures, rain, and direct sunlight. Enclosures installed in factories are also affected by factors such as dust, steam, and working heat. If, for example, an enclosure with insufficient waterproofing is used outdoors, water will get inside the enclosure, leading to malfunctions in the electrical circuits and similar items. Hence, enclosures are equipped with countermeasures that increase their weather resistance, waterproofing, dustproofing, and heat resistance against the operating environment.

Enclosure strength

Frames are installed in the corners of enclosures to increase their strength. L-shaped steel is used for the frames. Enclosures without frames are constructed by bolting or welding bent steel plates. Also, for enclosures that have frames, the frame surrounding the enclosure is also created by bolting or welding plates around the frame.

Adding frames to an enclosure increases its strength but also its weight. Frames are not necessary for small enclosures. However, subjecting large-scale enclosures without frames to even minor external forces may cause them to vibrate or their steel plates to split at the bolted parts, so frames are necessary.

Frames support the steel plates of an enclosure. Additionally, attaching bolts so they go through frames drastically increases the strength of the enclosure.

Enclosure dustproofing and waterproofing

There are holes in an enclosure to pass through wires for receiving power from and distributing power to devices outside the enclosure. An enclosure is also equipped with a fan as a countermeasure against heat buildup. Dustproofing is provided by packing in the gaps of the enclosure and around the wires that go through the holes in the enclosure.

Waterproofing is provided by waterproof packing in the gaps between the wires and the enclosure as well as by silicon or other sealants. Also, parts of the enclosure that open and close (such as the part where the enclosure and its door come into contact with each other) use a drain structure and waterproof packing to obtain high dustproofing and waterproofing.

The waterproofing and dustproofing of an enclosure are indicated by its enclosure rating specified with an IP code. It is beneficial to have higher dustproofing and waterproofing, but the increased quality also increases the manufacturing cost. Therefore, it is necessary to consider the quality and the cost according to the installation environment when determining the countermeasures to implement.

General enclosure rating guidelines are as follows: IP43 and higher for indoor installations, IP44 and higher for outdoor installations, and IP55 and higher for even harsher installation environments.

- A

- Waterproof packing

- B

- Drain

Necessity of Dimensional Measurement of Distribution Board, Switchboard, Control Panel, and Cubicle Enclosures

Distribution boards, switchboards, control panels, and cubicles are the high-voltage transformers of factories and large-scale buildings, so problems occurring in them may lead to manufacturing line stoppages or major accidents due to machines and automated devices stopping functioning.

Dust, rainwater, etc. inside an enclosure damages the electric circuits therein, which is a serious problem and takes a long time to recover from. At a large-scale factory, a line stopping for a day due to this type of problem may lead to losses so excessive that they put the future of the company in jeopardy. Hence, dimensional measurements are vital in checking whether enclosures are finished according to their designs and are installed correctly.

Distribution Board, Switchboard, Control Panel, and Cubicle Enclosure Dimensional Measurement Points

To ensure that large-scale enclosures have the required strength, the steel plates that act as the panels are attached to the frames that are the skeleton of the enclosure. This section explains the dimensional accuracies that are vital in attaching panels to frames with high accuracy.

Measurement points

Panels and frames are bolted or welded together. The key accuracy to determine whether the parts are joined together reliably is the flatness of the bolt holes and panels.

Dimensional accuracy of frame outer dimensions, hole pitch, and diagonals

Frames and panels are fixed together with bolts that go through them. Low dimensional accuracy of frame outer dimensions, hole pitch, and diagonals makes it impossible to match with the positions of the bolt holes on the panels, so dimensional measurement before assembly is important.

Frame perpendicularity and panel flatness accuracy

Low frame perpendicularity and panel flatness accuracy may impair the strength and durability with examples after installation including powerful stresses being applied to the bolt holes, cracks occurring from the bolt holes, and bolts being partially broken. The door fit also becomes worse, which may make it impossible to obtain the required dustproofing and waterproofing. Factors such as safety and durability are also determined in the ISO standards, so it is necessary to strictly measure the frame perpendicularity and panel flatness.

Problems of Dimensional Measurement of Distribution Board, Switchboard, Control Panel, and Cubicle Enclosures and Their Solutions

In the manufacturing of distribution boards, switchboards, control panels, and cubicles, it is important to not only measure the dimensions of the parts but items such as the perpendicularity and flatness after assembly. Conventionally, these measurements are performed using calipers, tape measures, and similar tools. However, measurements of products such as large-scale cubicles require multiple workers, so their measurements and adjustments take a lot of time and effort, affecting the delivery date. This has been a problem. Also, it is not possible to directly measure 3D shapes with hand tools such as tape measures and calipers. Therefore, the dimensions of 3D shapes were indirectly obtained with calculations from the values of the measurable points. The need to perform these calculations is the fundamental problem with this conventional method.

To solve these problems, the latest CMMs are used in an increasing number of cases. KEYENCE’s Wide Area Coordinate Measuring Machine WM Series enables high-accuracy measurement of the frames and panels of cases multiple meters in length with the wireless probe. Even recessed areas of products can be reached with no movement restrictions within the measurement range, which allows for easy single-person measurement with the simple operation of touching targets with the probe. Unlike measurements using measuring instruments such as calipers and tape measures, results do not vary, enabling quantitative measurement.

Dimensional measurement of frame outer dimensions, hole pitch, and diagonals

The frame outer dimensions and diagonal dimensions are large for large-scale enclosures, so their measurements are performed by multiple workers with tape measures. Furthermore, the pitch of the frame bolt holes and of the fan-mounting holes are measured one point at a time. However, the large number of measurement points makes this work require a lot of time. Measured values vary according to the angle and strength used to apply measuring instruments to the target, which causes variations in measured values among operators.

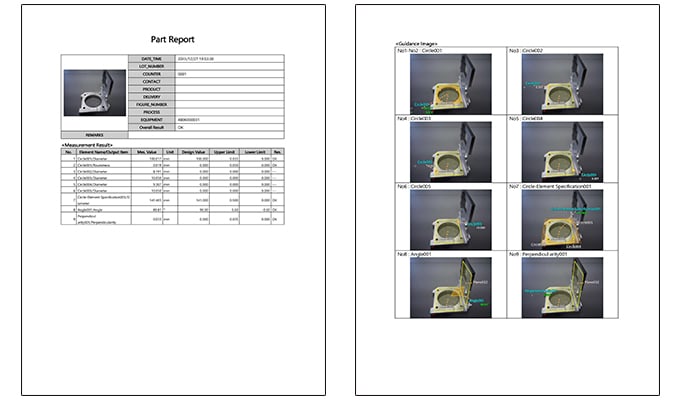

The WM Series enables the operator to perform measurements by simply touching the probe to the positions to measure. The frame outer dimensions, diagonal dimensions, and hole pitch can also be measured by simply touching with the probe. Even 3D distances and coordinates can be directly measured. This enables quick single-person measurement without variations in measured values among operators even when they are unfamiliar with measurement work. Furthermore, inspection reports can be automatically created with photos that allow you to understand measurement points at a glance. These inspection reports can not only gain you the trust of your business partners but also allow you to save measurement results as digital data, leading to higher efficiency of in-house data management.

Frame perpendicularity and panel flatness measurement

The frame perpendicularity and panel flatness affect the assembly accuracy of all the parts of an enclosure. Therefore, dimensional inspections are important not only during manufacturing but after assembly as well.

Frame perpendicularity and panel flatness are measured with tape measures. However, multiple workers are required for such measurements, making them inefficient. What’s more, it was difficult to convert warpage and curvature to values as flatness.

With the WM Series, even a single person can measure frame perpendicularity and panel flatness. The measured flatness and perpendicularity can be converted to values, and the distance between virtual lines can also be visualized. Furthermore, it is also possible to measure 3D dimensions and virtual distances such as the distance from an edge face on the outer frame to the diameter of a hole in the control panel and the distance from the center of a doorknob to an edge face.

Warpage and curvature can be displayed with color maps, allowing dimensions to be corrected accurately and easily. What’s more, the portability of the WM Series allows it to be brought into worksites and immediately measure the installation status.

Optimization of Dimensional Measurement of Distribution Board, Switchboard, Control Panel, and Cubicle Enclosures

The WM Series enables single-person measurement of distribution board, switchboard, control panel, and cubicle enclosures with the simple operation of touching targets with the wireless probe. In addition to the features introduced above, the WM Series has the following advantages.

- High-accuracy measurement over a large area

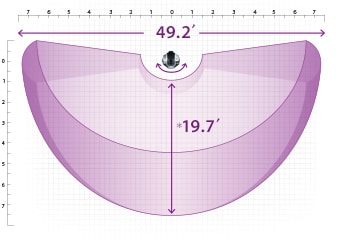

- A wide measurement range up to 15 m (49.2′) can be measured with high accuracy. The WM Series is equipped with the navigation measurement mode, which enables measurement at the same point according to a memorized measurement procedure, allowing anyone to obtain the same measurement data.

- Measurement results can be output as 3D models

- The measured elements can be exported as a STEP/IGES file. 3D CAD data can be created on the basis of the measurement results of an actual product even if no drawing is available.

- Easy-to-understand interface

- CMM interfaces are often a mess of complex and unfamiliar commands. The WM Series provides intuitive operation using images and icons, so anyone can easily understand how to operate the system.

- The portable body can be placed on-site

- The main unit can be carried around on the cart. The WM Series can be brought into worksites and immediately measure the status of the work.

The WM Series strongly supports analysis, such as comparison with 3D CAD data, as well as dimensional measurement of distribution board, switchboard, control panel, and cubicle enclosures. It dramatically improves the efficiency of manufacturing of enclosures and of work indispensable for their installation and quality management.