Detection based on “Contact Measurement”

What is a Contact Positioning Sensor?

Outline

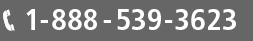

As the name indicates, this is a sensor measuring the position of a target by directly contacting it. When the height of the spindle changes as shown in the figure on the right, the sensor internally calculates the amount of displacement. Contact Positioning Sensors are mainly used for detecting the height, thickness, or warpage of the target.

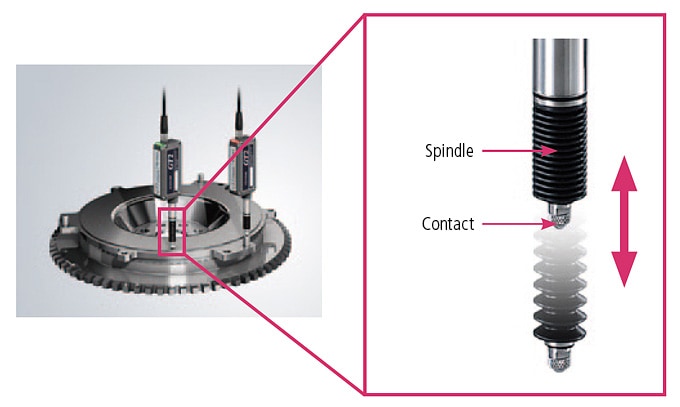

Air push type measuring by extending a spindle

Since measurement is possible with the sensor head being fixed, no mechanism is required to move the sensor head. This saves installation space and greatly reduces man-hours during installation.

Features

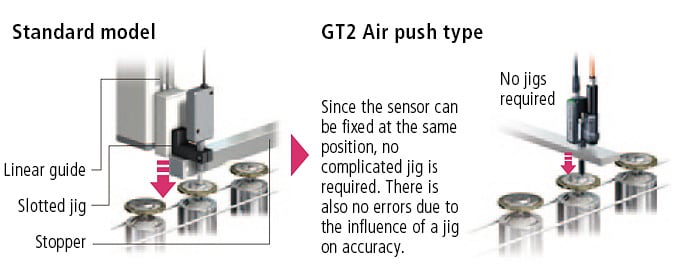

The following table shows typical characteristics that vary depending on the detection system.

Sensor type comparison based on the detection method

| Item | Inductive | Optical | Ultrasonic | Laser focus | Contact |

|---|---|---|---|---|---|

| Detectable target | Metal | Almost all materials | Almost all materials | Almost all materials | Solid |

| Measuring distance | Short | Normal | Long | Short | Short |

| Accuracy | High | High | Low | High | High |

| Response speed | Fast | Fast | Slow | Normal | Slow |

| Dust, water, oil, etc. | Unaffected | Normal | Normal | Normal | Unaffected |

| Measuring surface | Normal | Small | Large | Small | Small |

| Item | Inductive | Optical | Ultrasonic |

|---|---|---|---|

| Detectable target | Metal | Almost all materials | Almost all materials |

| Measuring distance | Short | Normal | Long |

| Accuracy | High | High | Low |

| Response speed | Fast | Fast | Slow |

| Dust, water, oil, etc. | Unaffected | Normal | Normal |

| Measuring surface | Normal | Small | Large |

| Item | Laser focus | Contact |

|---|---|---|

| Detectable target | Almost all materials | Solid |

| Measuring distance | Short | Short |

| Accuracy | High | High |

| Response speed | Normal | Slow |

| Slow | Normal | Unaffected |

| Measuring surface | Small | Small |

-

Detection based on “Changes in Eddy Current”

What is an inductive displacement sensor?

Inductive displacement sensors -

Detection based on “Contact Measurement”

Principle and types of Contact Positioning Sensors

Contact Positioning Sensors