|

|

|

|

| Our Next Generation, Optical Inspection system is more useful than ever before after our long-awaited software upgrade. Click to learn more about the new, added capabilities! |

|

|

|

|

|

|

|

|

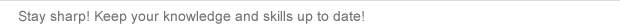

This technical guide introduces examples of how our non-contact 3D measurement system can benefit research and development, including:

• Comparing parts to their CAD model to understand prototype differences

• Visualizing surface changes to better understand part behavior |

|

|

|

|

|

|

|

|

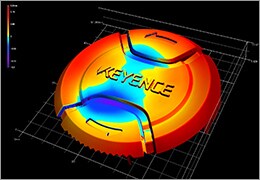

| Quickly image and measure with the VHX Digital Microscope. Users can easily perform 2D/3D measurements and many other advanced analysis techniques: grain sizing, particle counting, etc. automatically. |

|

|

|

|

|

|

|

|

| The XM Series allows all operators to check any 3D/GD&T measurements at their worksite; Bringing the QC lab directly to your manufacturing floor. |

|

|

|

|

|

|

|

|

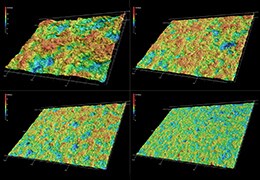

| The VK-X is able to display multiple 3D images side-by-side so users can easily visualize the differences between surfaces and even quantify differences due to changes in manufacturing or wear over time. |

|

|

|

|

|

|

|

|

| Thanks to our latest observation and measurement instruments, KEYENCE can provide you with the optimal solutions to your applications directly on-site. Contact us today to schedule a demo!

|

|

|

|

|

|

|

|

|

|

|

| Contact |

|

North American Headquarters:

KEYENCE CORPORATION of America

Sales & Marketing Head Office

500 Park Boulevard, Suite 200, Itasca, IL 60143

TOLL FREE DIRECT CALL: 1-888-KEYENCE

[1-888-539-3623]

E-mail : tech@keyence.com

Web Site : https://www.keyence.com |

|

Corporate Office

669 River Drive, Suite 403

Elmwood Park, NJ 07407

Phone: 1-201-930-0100 |

|

|

Company and product names mentioned in this email and linked webpage are either trademarks or registered trademarks of their respective companies.

Copyright (C) 2019 KEYENCE CORPORATION. All Rights Reserved. |

|

|