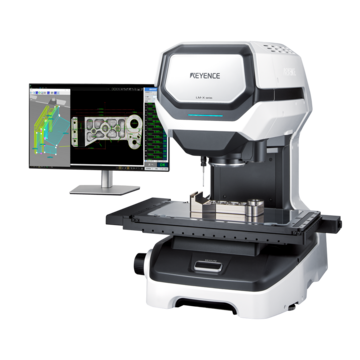

Multisensor Measurement System

Multisensor Measurement System

KEYENCE's LM-X Series Multisensor Measurement System provides high-accuracy measurement with simple button-press operation. There is no need for time-consuming positioning or fixturing, and the system automatically detects and measures the position and orientation of the part, no matter where it is placed on the stage. Since the system can be easily set up and used, anyone can easily get highly accurate measurements and inspection reports.

Product Lineup

High-accuracy (±0.1 µm) measurement can be performed easily just by placing the part on the stage and pressing a button. Three measurement methods are available: high-accuracy image measurement, non-contact height measurement via a multi-color laser, and contact measurement via a touch probe. This product drastically reduces the dimensional measurement time of complex parts and ensures accurate measurements with no variations between results obtained by different operators.

Features

No Time-consuming Positioning or Coordinate Creation Required

The location and orientation of parts placed on the stage are automatically detected. This eliminates the need for conventional labor-intensive positioning, creating coordinates, and preparing fixing jigs.

-

1STEP1 : Place

-

2STEP2 : Press

-

3STEP3 : Obtain results

Three Different Measurement Methods for Fast and Easy High-accuracy Measurement

Highly-accurate measurement along the X, Y, and Z axes.

-

1Touch probe : Measurement of three-dimensional parts

-

2Ultra-high-resolution camera : High-accuracy image measurement

-

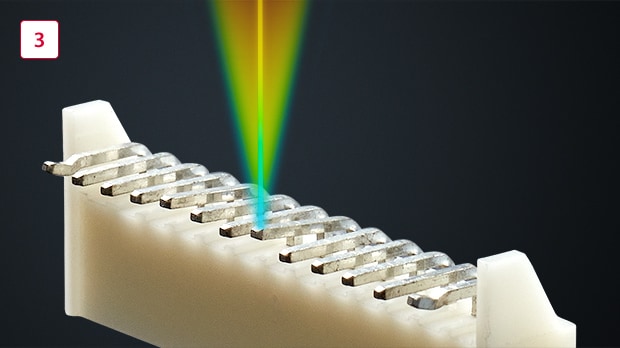

3Multi-color laser : Instant height measurement

Touch probe : Measurement of three-dimensional parts

Ultra-high-resolution camera : High-accuracy image measurement

Multi-color laser : Instant height measurement

Measure up to 5000 Locations on up to 1000 Parts

Fast, simultaneous measurement is possible even when multiple parts are placed on the stage. There is also no need to use fixing jigs.

Large Low-Vibration Stage for High-Speed Measurement

The large stage has a maximum measuring area of 175 × 325 mm ø6.89" × 12.80" and a working height of 75 mm 2.95". The new design reduces the friction between the motor and feed screws as much as possible, allowing for quick and stable measurement without fixing the part in place.

Frequently Asked Questions About Multisensor Measurement System

The Keyence LM-X Series is considered a multisensor measurement device by combining 3 sensor types (vision, probing, and laser) for automated dimensional inspection. These 3 sensor types can be used together or separately to cover a wide range of inspection requirements or needs.

The LM-X Series combines 3 measuring tools including a 20 megapixel CMOS camera vision system, a configurable touch probe module, and a white confocal laser.

Confocal lasers are advantageous over triangulation lasers because of the single optical axis. This allows the system to see into holes without dead zones, no loss of data near step height changes, and allows for measurements on curved surfaces. The beam spot size will also be the same size throughout the measurement range, so the accuracy is the same regardless of where you are in the measurement range.

While the best method/practice for height measurement is dependent on the part and print, in general the confocal laser is a powerful tool to measure surface flatness extremely efficiently regardless of the number of measurement points. The focal height tool is primarily used for rough surfaces or measuring the maximum/minimum height across a larger area.

In addition to a larger stage size, the LM-X series offers programmable measurement sensors including a configurable touch probe and confocal laser, previously not available on the LM-1100.

The rotary attachment unlocks 3D rotational inspection of parts including total run-out, coaxiality, roundness, cylindricity and more. In addition to rotational measurement inspection, the rotatary attachment allows multiple part orientations to be included within a single program.

Please refer to our brochure for an in-depth specification sheet. The LM-X Series camera in a single FOV can hold as low as +/- 2 micron with our wide field mode and +/-0.7 micron in our high precision mode. Our touch probe and confocal laser both hold about a +/-5 micron accuracy specification.