Intuitive Vision System

CV-X series

Intuitive Vision System CV-X series

One System Does It All!

Reliable Solutions for All Inspection Needs

- Intuitive, icon-driven vision system allows anyone to setup reliable product inspections

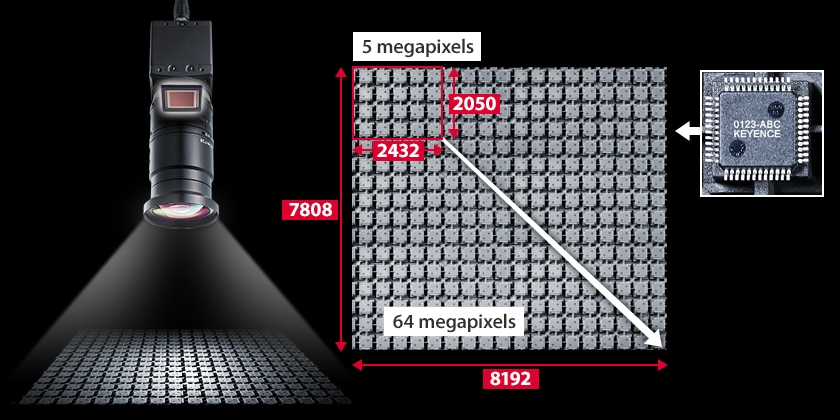

- 64 and 21 megapixel cameras

- All in one vision system

The CV-X Series is an innovative, user-friendly vision system that uses high-speed cameras to solve inspection applications across all manufacturing industries. The CV-X vision system incorporates cameras and lighting to stably image parts in-line to improve efficiency and ensure quality. Industries served include automotive, electronics, medical, food and packaging, and any process that requires inspection on high-volume parts. Common applications include defect detection and surface inspection, presence of parts and features, assembly verification, vision guided robotics, measurement, and code reading.

Features

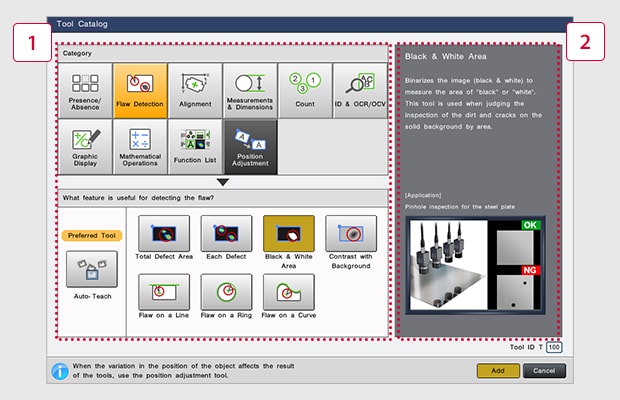

Just select the inspection category from the tool catalog.

Intuitive, Icon-Driven Vision System Allows Anyone to Setup Reliable Product Inspections

A tool catalog that makes it easy to understand which tool is best to use from the features that you wish to inspect has been adopted. This makes it possible for the users to select the best tools without comprehensively understanding all the included algorithms.

-

1TOOL CATALOG

-

2APPLICATION NAVIGATOR

64 and 21 Megapixel Cameras

The new high-resolution 64 megapixel camera significantly improves accuracy in conventional inspections. A single image capture delivers a wider range with clear details for increased inspection stability.

ALL in ONE Vision System

CV-X is a global standard model with the latest algorithms embodied in a user-friendly design. The CV-X Series offers solutions to any of your inspection needs and stable operation at any manufacturing site.

Conventional camera

Surface conditions interfere with extraction.

Multi-spectrum image capture

Extraction of only shape (irregularity) information regardless of surface conditions.