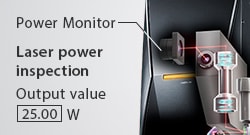

Full-Field Auto-Focus Eliminating Engraving Defects

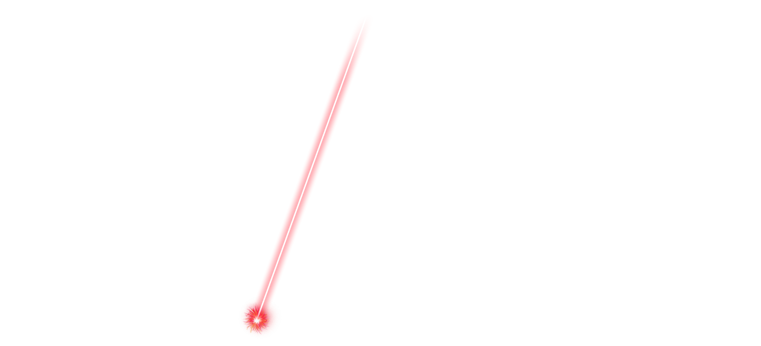

Laser engravers use a lens to focus light to engrave, so even slight height deviations can cause engraving defects.

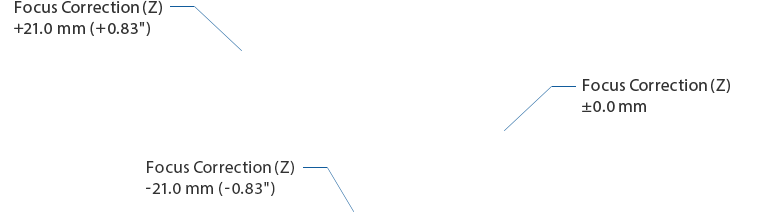

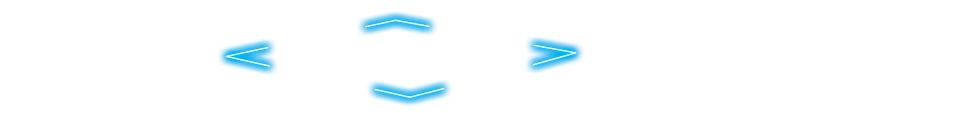

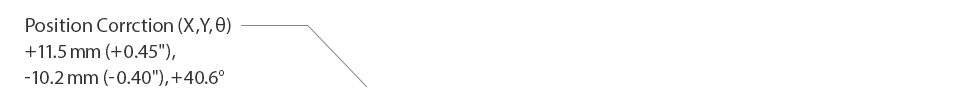

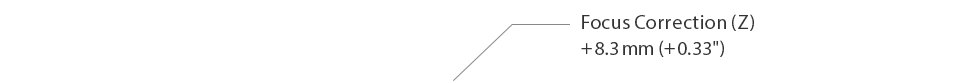

The MD-X Series is equiped with a built-in distance sensor, which tracks any unintentional changes in height or incline to eliminate those engraving errors.