|

|

There are two main methods for preventing electrostatic damage: 1) Prevent discharge to the device or 2) Lower the level of static electricity.

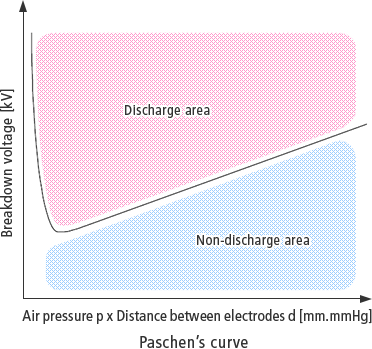

Most people know that discharge is normally less likely to occur over long distances. Therefore, discharge can be prevented simply by keeping an adequate distance from the charged object. When the voltage between two electrodes slowly increases, the voltage between the electrodes at the moment of discharge is known as the breakdown voltage. The breakdown voltage V [V] is represented in the following equation as the function of the product of the air pressure p [pressure] and the distance between the electrodes d [mm].

V = f(pd)

This is called Paschen’s Law. In normal air pressure, 1 kV of discharge is produced per 1 mm.

An extremely effective method of preventing electrostatic damage involves reducing the overall amount of static electricity in the surrounding area. The area kept at a constant level of static electricity in order to prevent damage due to electrostatic discharge is called the ESD Protected Area (EPA). The following types of methods are generally used to lower static electricity.

An extremely effective method of preventing electrostatic damage involves reducing the overall amount of static electricity in the surrounding area. The area kept at a constant level of static electricity in order to prevent damage due to electrostatic discharge is called the ESD Protected Area (EPA). The following types of methods are generally used to lower static electricity.

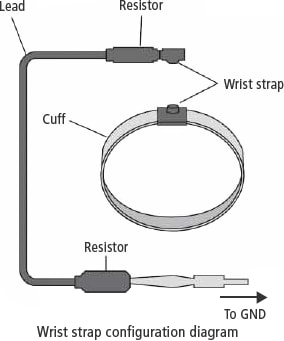

By keeping the operator constantly grounded, this method can prevent static electricity from charging the human body. In an EPA, the following expression shows the conditions for grounding resistance while a wrist strap is worn.

0.75 ≤ Rg ≤ 35 [MΩ]

One of the required conditions for a wrist strap is that the wrist strap can be easily removed in an emergency. The grounding cable should be set to unfasten with a force between 5 and 25 N.

Furthermore, a wrist strap cannot be used indefinitely. Therefore, it should undergo periodic inspection. The optimum frequency for inspection is before every use, but performing these inspections every time can take a large amount of time. In order to prevent this waste of time, a product known as a “wrist strap monitor” was developed. This monitor sounds an alarm or produces an electronic signal if the connection to the operator is broken.

The methods introduced above can be used to prevent electrostatic discharge by grounding the person or surrounding devices. However, there are many situations where static electricity on the workpiece cannot be eliminated with grounding. In these situations, the most common method involves using an ioniser.

Of the above three types of electrostatic damage, the charge device model (CPM) represents the most common discharge model. Therefore, using an ioniser to eliminate static is the most effective method in most cases.

1-888-KEYENCE

(1-888-539-3623)