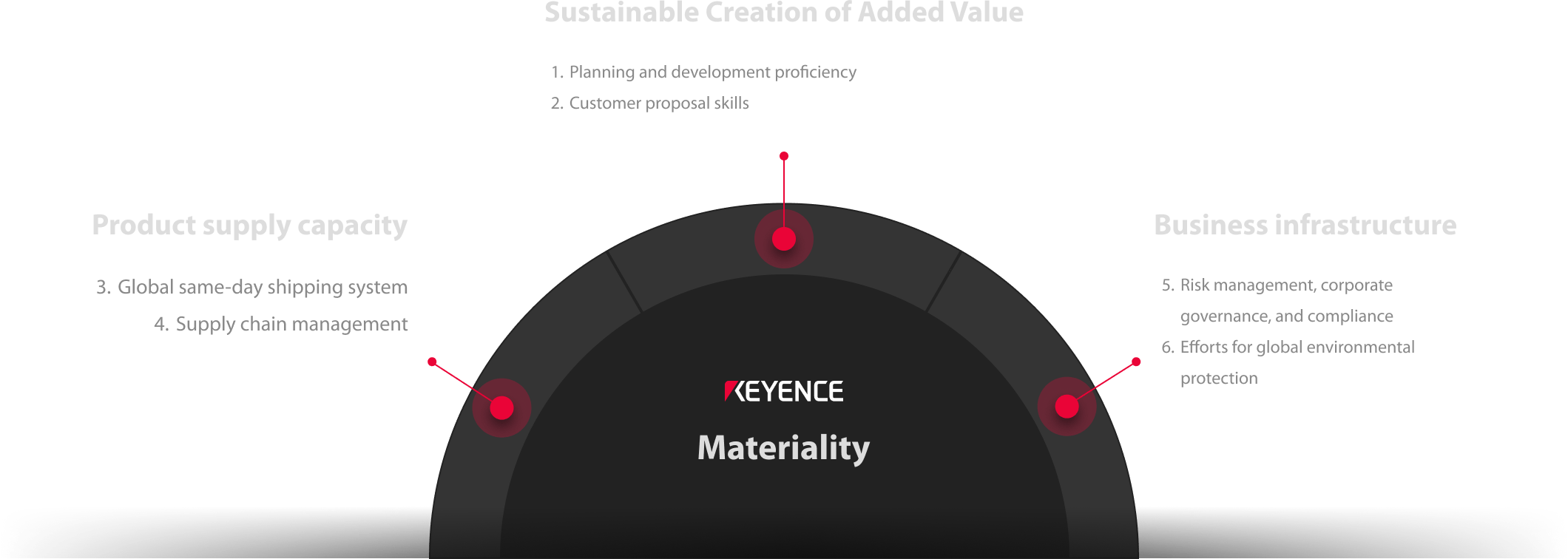

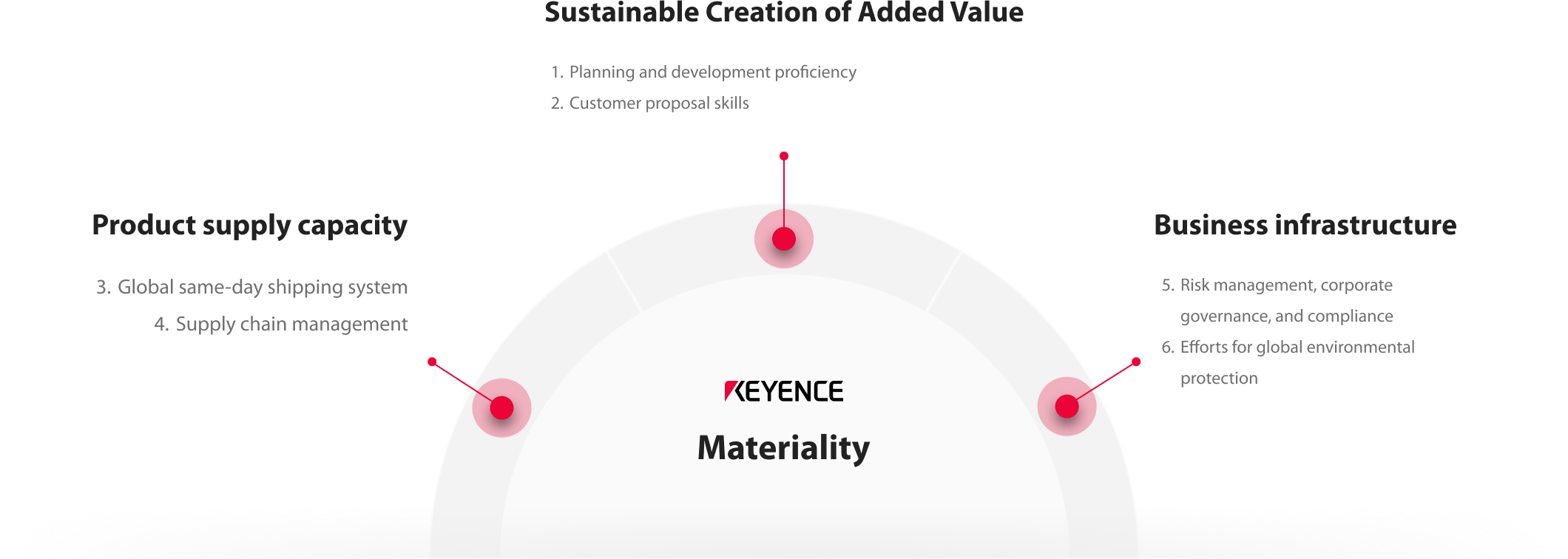

KEYENCE’s Materiality

Sustainable Creation of Added Value

1.Planning and development proficiency

1.Planning and development proficiency

Contributing to customer automation, quality improvement, better R&D efficiency, and higher productivity

Ensuring the lasting survival of the company has been a core management philosophy since the founding of KEYENCE. To ensure lasting survival, a company must both contribute to and be supported by society. It is our mission to accurately grasp the various potential needs at customer sites and deliver solutions through our products. To continue creating novel values is our social contribution, which we believe, will lead to a sustainable creation of added value.

Continuous creation and provision of high-added value products that contribute to solving problems in the world

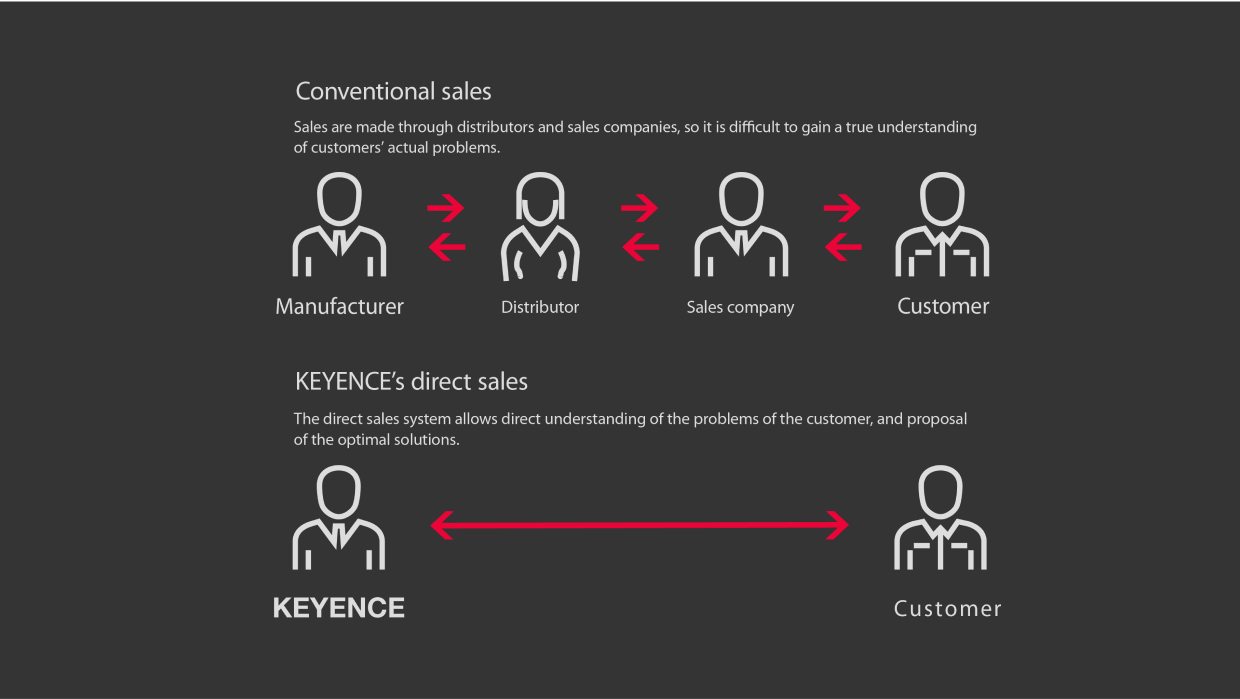

We accurately identify the potential needs and problems of our customers through direct sales, and using that information we plan and develop world-first and industry-first products, not for specific fields or as custom-made products, but as standard products that are used in a wide range of fields and industries.

2.Customer proposal skills

2.Customer proposal skills

Understanding potential customer needs and making problem-solving proposals for customer sites

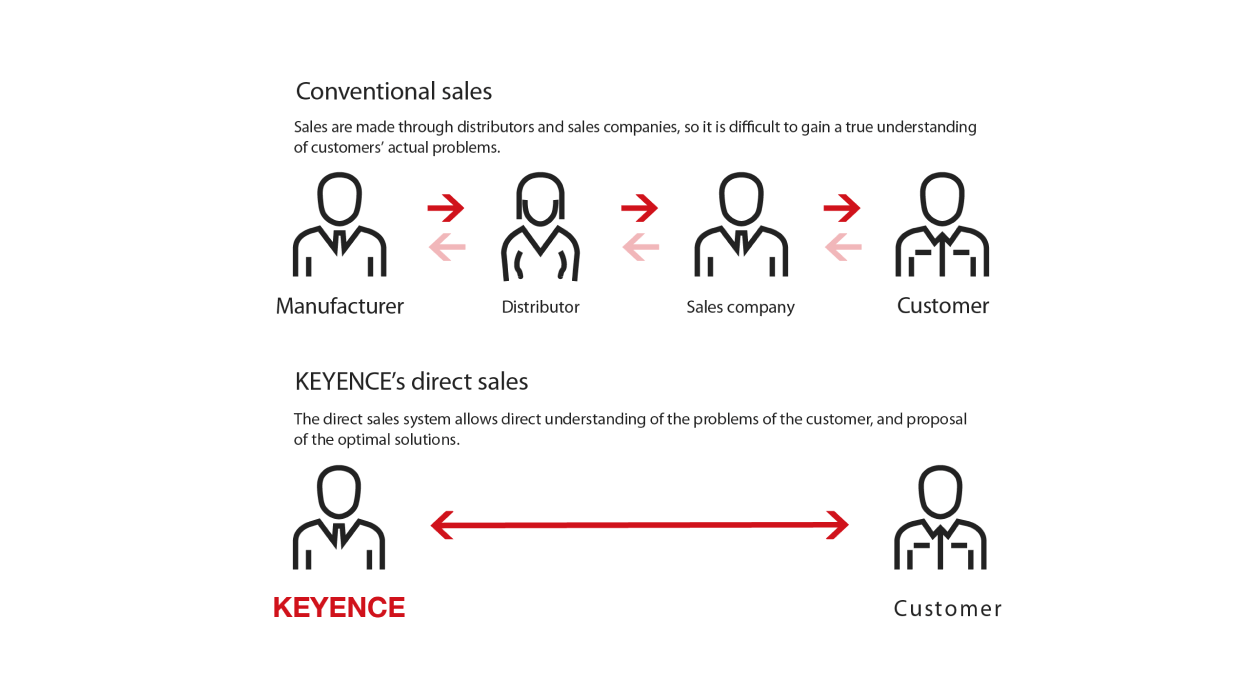

In order to present customers with unique products that are world or industry firsts, it is critical that our sales personnel have a deep understanding of the products and applications. Thanks to our system that uses direct sales rather than distributors, our salespeople can propose appropriate and ready-to-implement solutions using our products, based on a direct awareness of the problems and needs of each customer. And building awareness of each customer’s potential needs leads to the development of the next innovative product.

Stepping up the Global Direct Sales system

At KEYENCE, we recognize increasing our sales ratio outside Japan as one of our business challenges. Frankly, our current overseas sales ratio does not live up to our potential. We firmly believe that, in overseas markets where there is significant room for growth, our direct sales business model has the potential to take hold and lead to a major expansion in sales.

Product supply capacity

3.Global same-day shipping system

3.Global same-day shipping system

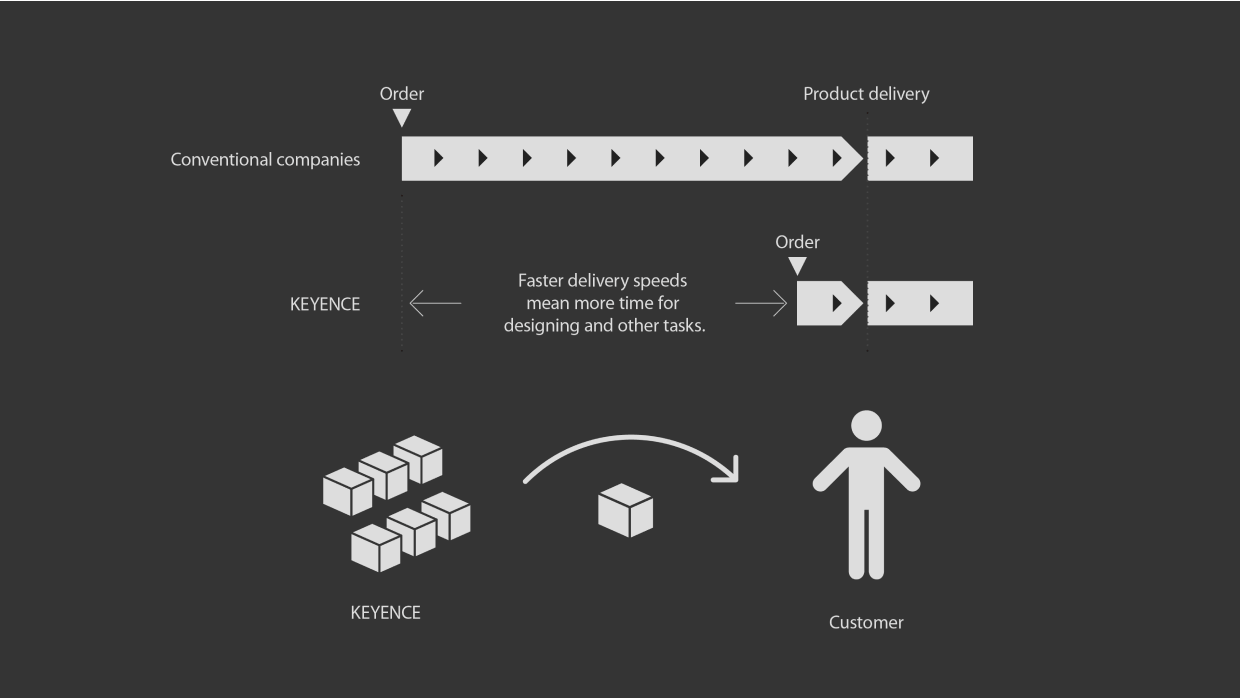

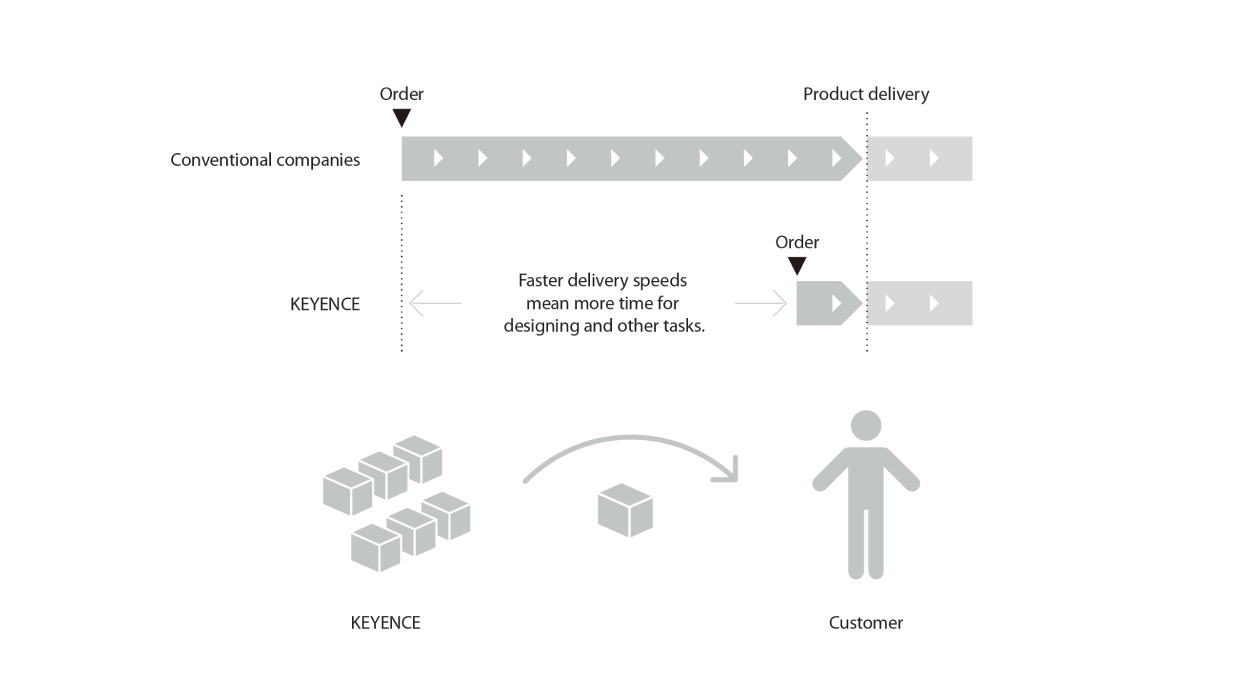

Our products are shipped the day they are ordered around the world. This means that our customers don’t need to keep extra stock―they can get what they need in their preferred volume when they need it. Customers can select the optimal product without worrying about different delivery dates for individual products, so they have more time to consider specifications.

4.Supply chain management

4.Supply chain management

In order to achieve lasting promotion of added value as a company, it is critical to provide a workplace where people respect each other’s humanity and have a real sense of fulfillment in their work. Guided by this principle, at KEYENCE we have emphasized the creation of a workplace environment where it is easy to work, both physically and mentally. We have a strong awareness of the importance of conducting business activities with not only legal compliance but also the highest of ethical standards, while paying attention to human rights issues and other challenges that arise with globalization. Based on this awareness, we have implemented a Group-wide Code of Conduct that mandates respect for human rights, such as by eliminating discrimination, child labor, and forced labor. We will continue our efforts for human rights issues in the value chain.

Business infrastructure

5.Risk management, corporate governance, and compliance

5.Risk management, corporate governance, and compliance

Only a sound business foundation that supports continued growth will create greater added value. We will build a corporate governance system in which decision-making (execution) and supervision functions work soundly, and further strengthen our risk management and compliance systems to promote business activities based on high ethical standards.

6.Efforts for global environmental protection

6.Efforts for global environmental protection

To ensure the lasting survival of the company, we believe that it is absolutely essential not only to develop products that are useful to society and that address the issues faced by our customers, but ultimately to be the kind of company that is supported by a society that includes our customers, employees, business partners, and shareholders. We aim to achieve sustainable growth and a high level of profitability through the creation of products with high levels of added value and continuous contribution to society, while not only complying with laws and regulations but also showing care for the global environment by means such as reducing energy and resource consumption.

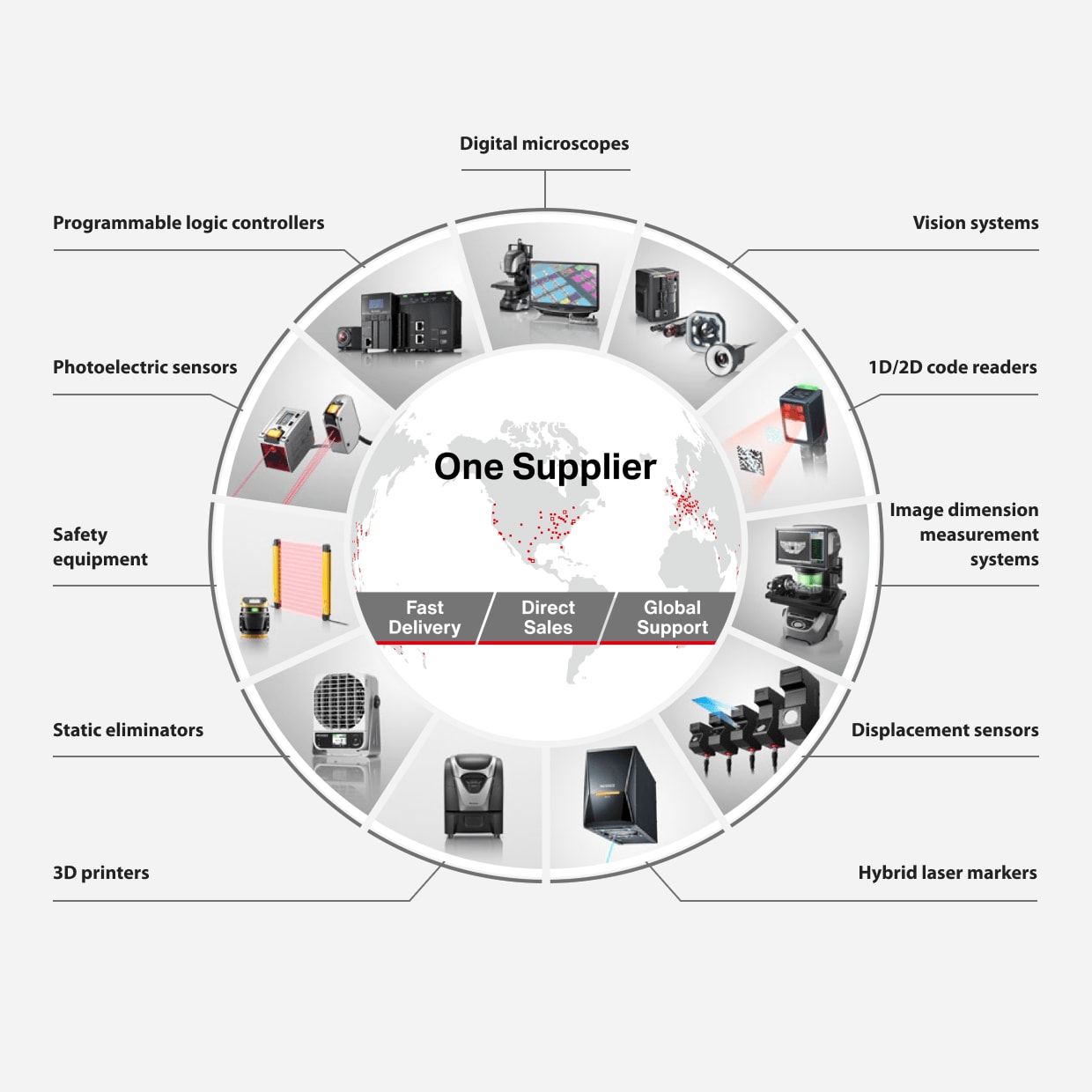

A Rich Lineup of Innovative Products

One-Stop Product Lineup for Total Support

KEYENCE plans and develops products that are indispensable for manufacturing, and provides proposal-type direct sales to offer the best products to meet each customer’s particular needs. This range of products includes a variety of factory automation sensors such as general-use sensors and displacement sensors, measurement systems, PLCs, barcode readers, laser markers, digital microscopes, and 3D printers. Our capability to be a single supplier that can solve a variety of issues is one of the core reasons that KEYENCE is many manufacturers’ first choice.

A Broad Customer Base

A Range of Products Used in a Wide Variety of Applications

At KEYENCE, we plan and develop our products based on a grasp of not only the current needs of our customers but their potential future needs as well, so that they can be utilized in a wide range of industries all over the world. By proposing the optimal product application for your industry—whether that industry be automobiles, semiconductors, LCDs, electronic devices, IT equipment, information and telecommunications, steel and other metals, food, medicine, or logistics—we have created a business environment that is not bound by the trends in specific industries or customers. Today, KEYENCE’s products are used by more than 350,000 companies around the globe.

Business Fields

Total Support, from R&D to Retail

KEYENCE develops leading-edge products that support our customers’ technological innovation, which in turn leads to innovation in manufacturing itself. Our business fields cover all processes, from R&D to manufacturing, assembly, inspection, and logistics.

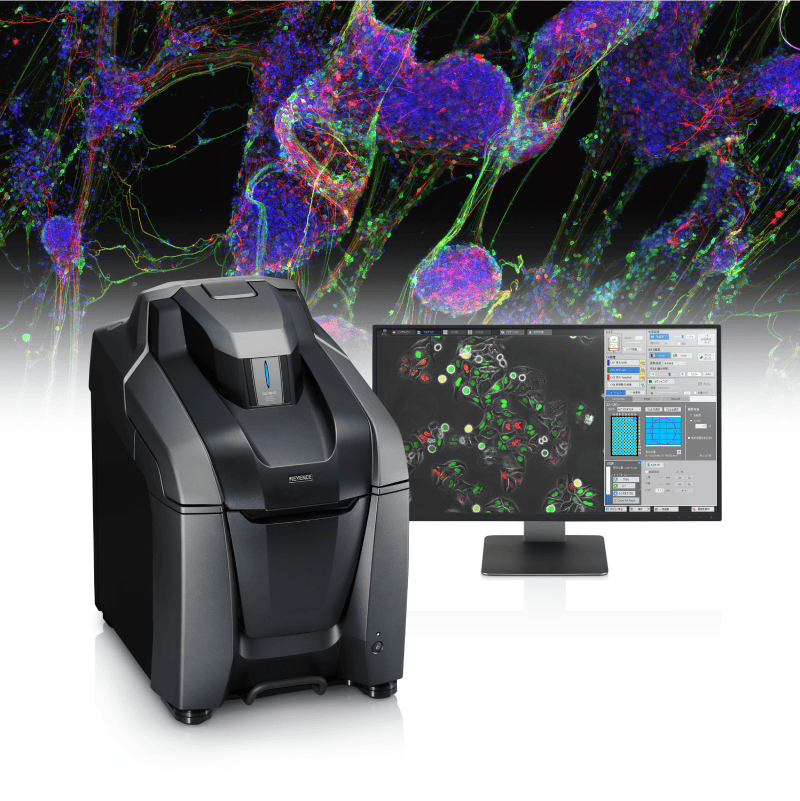

Research and Development

KEYENCE’s products contribute to a wide range of research and development fields—including regenerative medicine applications such as iPS cell analysis—as well as scientific and technological applications such as aerospace manufacturing. These accomplishments are in addition to KEYENCE’s contribution to conventional applications in manufacturing R&D.

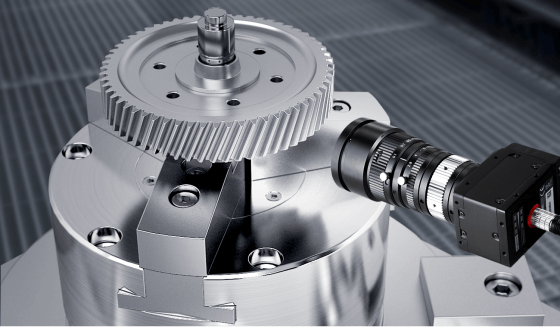

Factory Automation

We are currently living through the so-called Fourth Industrial Revolution, and the emergence of smart factories is accelerating around the globe. Sensors and measuring instruments play an absolutely vital and ever expanding role in automation and data collection in these facilities. Our rich array of products can contribute to manufacturing by handling applications in a wide range of industrial fields.

Quality Management

Manufacturing sites demand production that is both high quality and efficient. With impressive inspection accuracy and processing speeds beyond the limitations of the human eye, KEYENCE products contribute to achieving the highest quality.

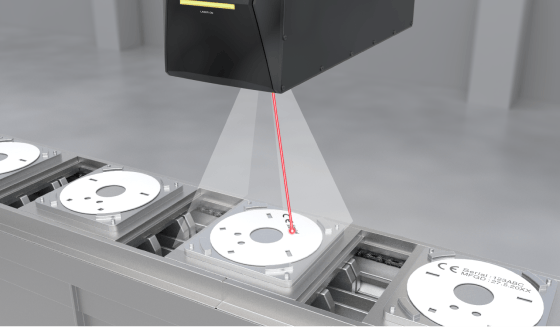

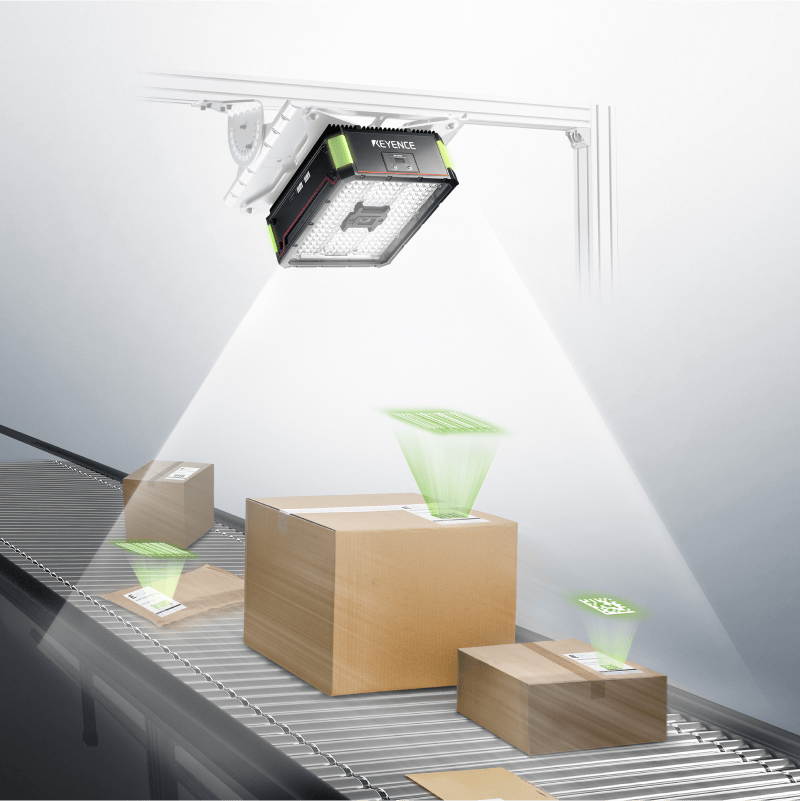

Traceability

KEYENCE products can help implement stringent product management—from raw material procurement to production and shipping—to contribute to the creation of safe, reliable products that bear clear identification of when, where, and by whom they were manufactured.

Logistics

With the growing ubiquity of e-commerce and IT, the volume of physical distribution is ever increasing. To meet diverse consumer demand, automated transfer systems, robots, and other methods are being used to construct more efficient logistics systems.

Retail

Keeping track of things like inventory and order quantity at retail stores is critical to improving work efficiency and reducing losses. By improving usability and reading performance, we are contributing to work efficiency.

A Business Model That Creates High Added Value

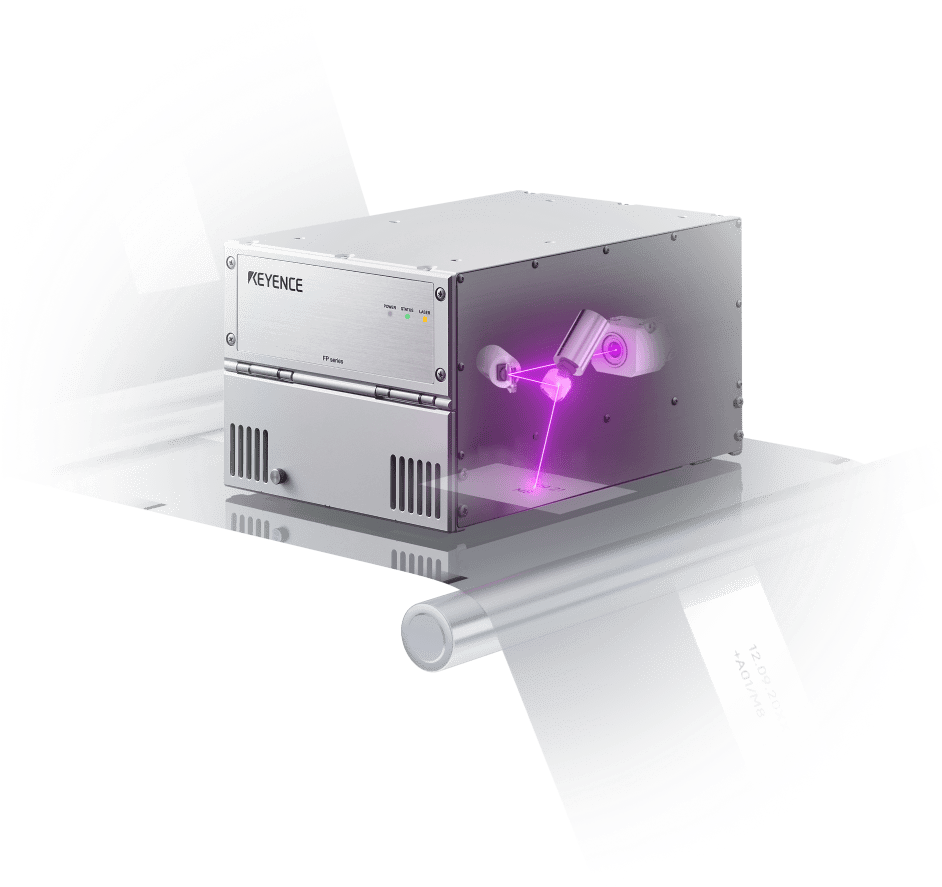

The Capacity to Plan and Develop Products That Are Industry and World Firsts

Roughly 70% of KEYENCE’s new products are either world firsts or industry firsts. We accurately identify the potential needs and problems of our customers through direct sales, and using that information we plan and develop world-first and industry-first products, not for specific fields or as custom-made products, but as standard products that are used in a wide range of fields and industries. Instead of commercializing exactly what the customer wants, we determine their unnoticed, latent needs and develop the kind of innovative products that they could not have imagined. This is the source of KEYENCE’s high level of added value.

Case Studies: KEYENCE Products Providing New Value to Solve Customer Problems

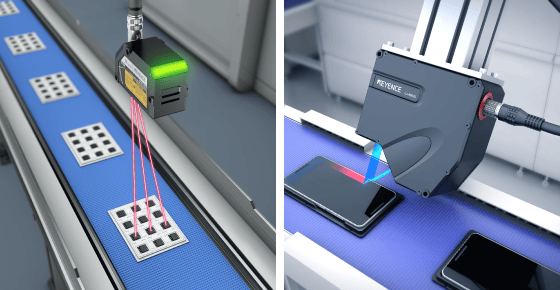

LJ-S8000 Series

Before

Conventional problems

Plane inspection problems

- Difficulty inspecting height

-

- A separate process is required for height inspection, leading to increased cycle times.

- Adverse effects from environmental changes

-

- Adverse effects from changes in the inspection environment—including ambient light and target color, pattern, and surface conditions—make inspection unstable.

- Start-up takes too long

-

- Adjusting lenses, lighting, and other components during tooling changes or line deployment takes a lot of time.

After

Solution

Advantages of 3D inspection

- Width, height, area, volume—one device for all your inspection needs!

- Resistant to environmental changes

-

- The built-in laser light source eliminates the need for adjusting lighting conditions. Single-wavelength specialized optical system also ensures no adverse effects from ambient light.

- Start-up with minimal effort

-

- Full-focus imaging means there’s no need for adjustment, allowing for easy installation on existing equipment.

IV4 Series

Before

Conventional problems

Difficult to select lighting and lenses and configure detection settings

Conventional vision systems require specialized knowledge for everything from selecting devices to configuring detection settings.

Difficult to readjust the system when trouble occurs

Readjusting the system after a problem occurs is difficult without specialized knowledge in everything from capturing images to changing inspection settings and parameters.

After

Solution

All-in-one lighting, lens, and camera design

All of the necessary devices are included in this all-in-one system, eliminating the need for specialized knowledge when selecting components.

AI-based optimization of everything from imaging, configuring settings, and operation

The built-in AI makes setting the ideal imaging conditions and extracting recommended images easy. Unlike conventional systems that require specialized knowledge, anyone can set up and use the system.

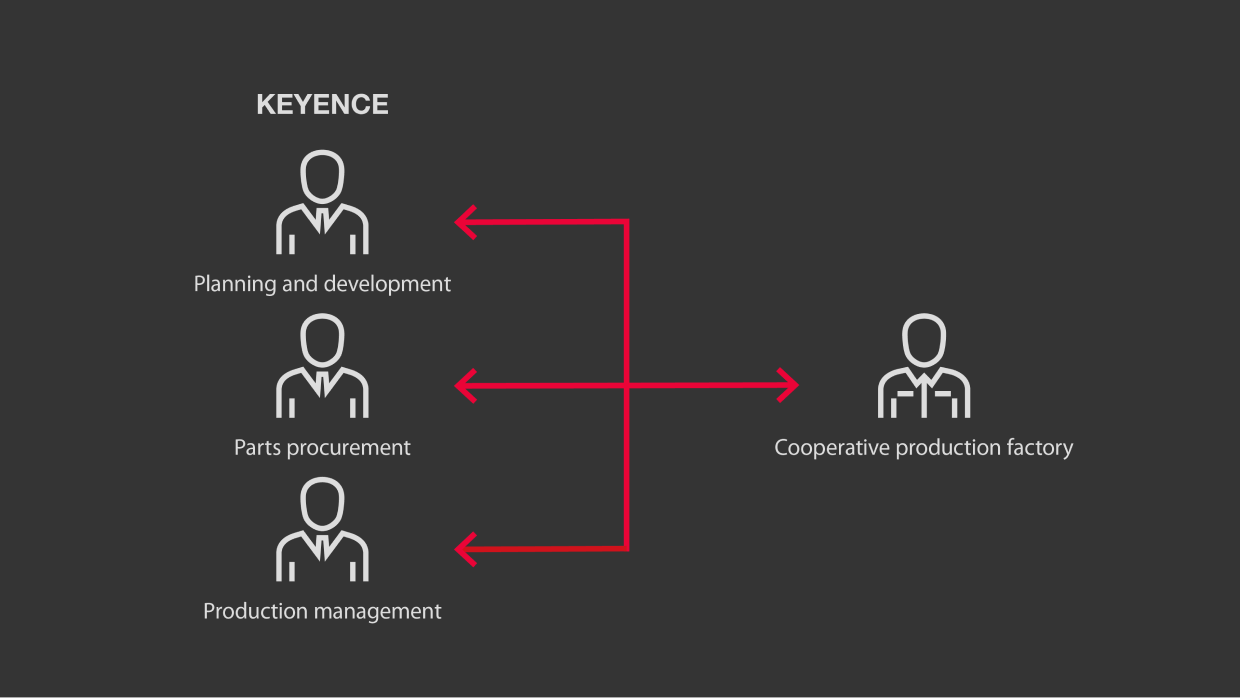

Fabless Production

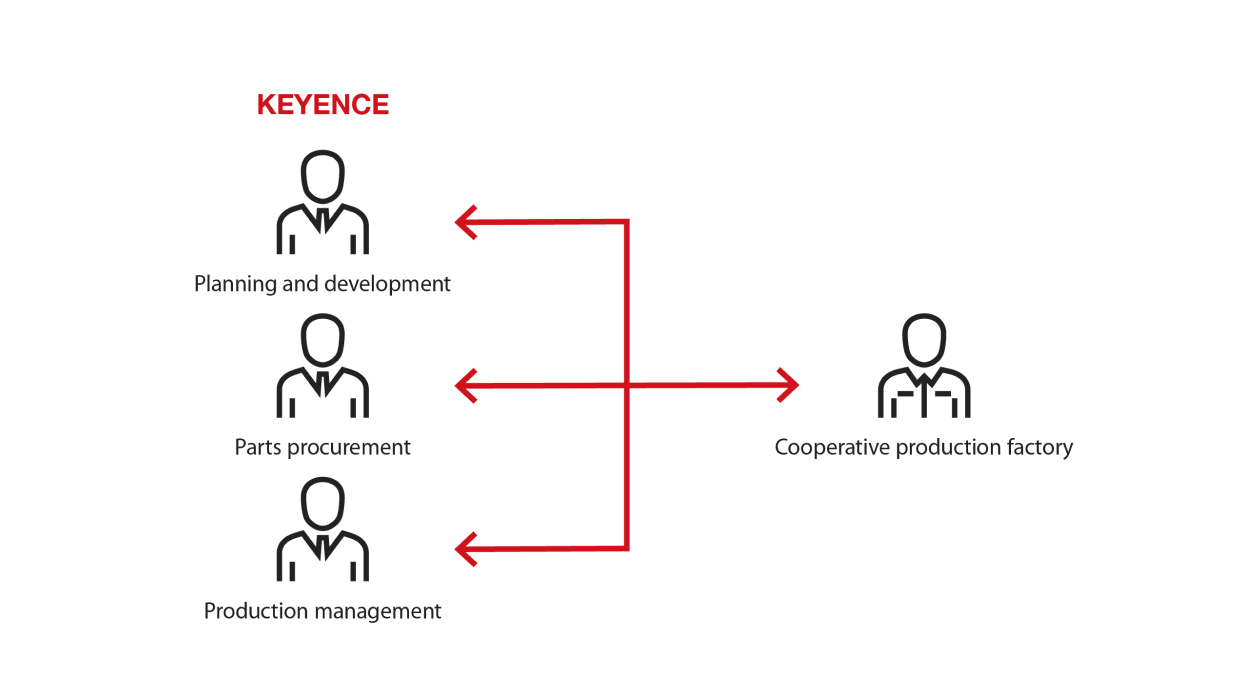

Rather than doing production in-house, we outsource to partner companies both in Japan and abroad. This means that we can control capital investment and select plants with the optimal equipment and technology according to each product’s characteristics. The KEYENCE department in charge procures the materials required for product planning, development, design, and production, and the production technology, production planning, and quality control departments are deeply involved in the production of products to build systems for mass-producing quality products while accumulating knowledge and technology related to their production in-house.

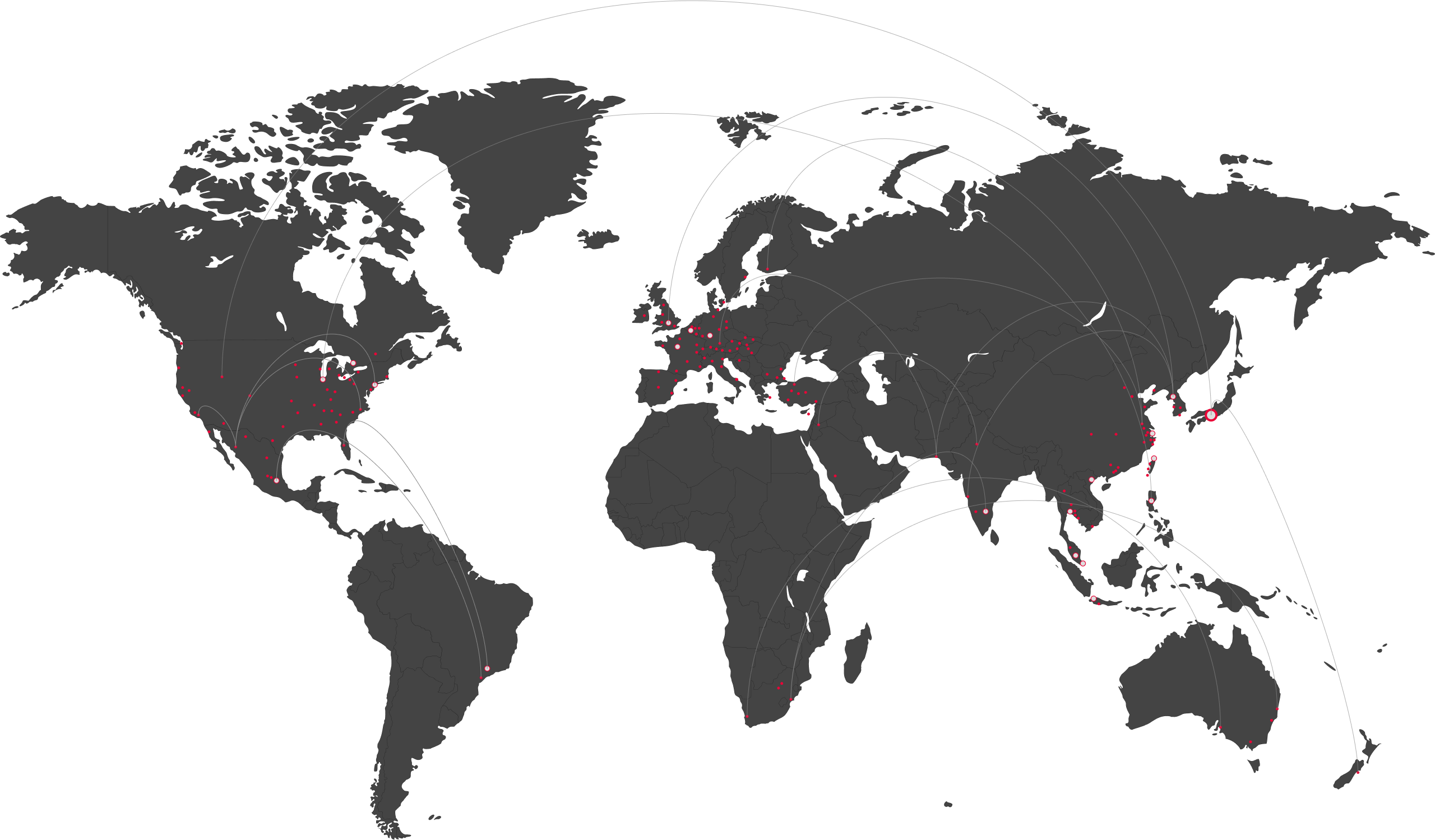

Direct Sales

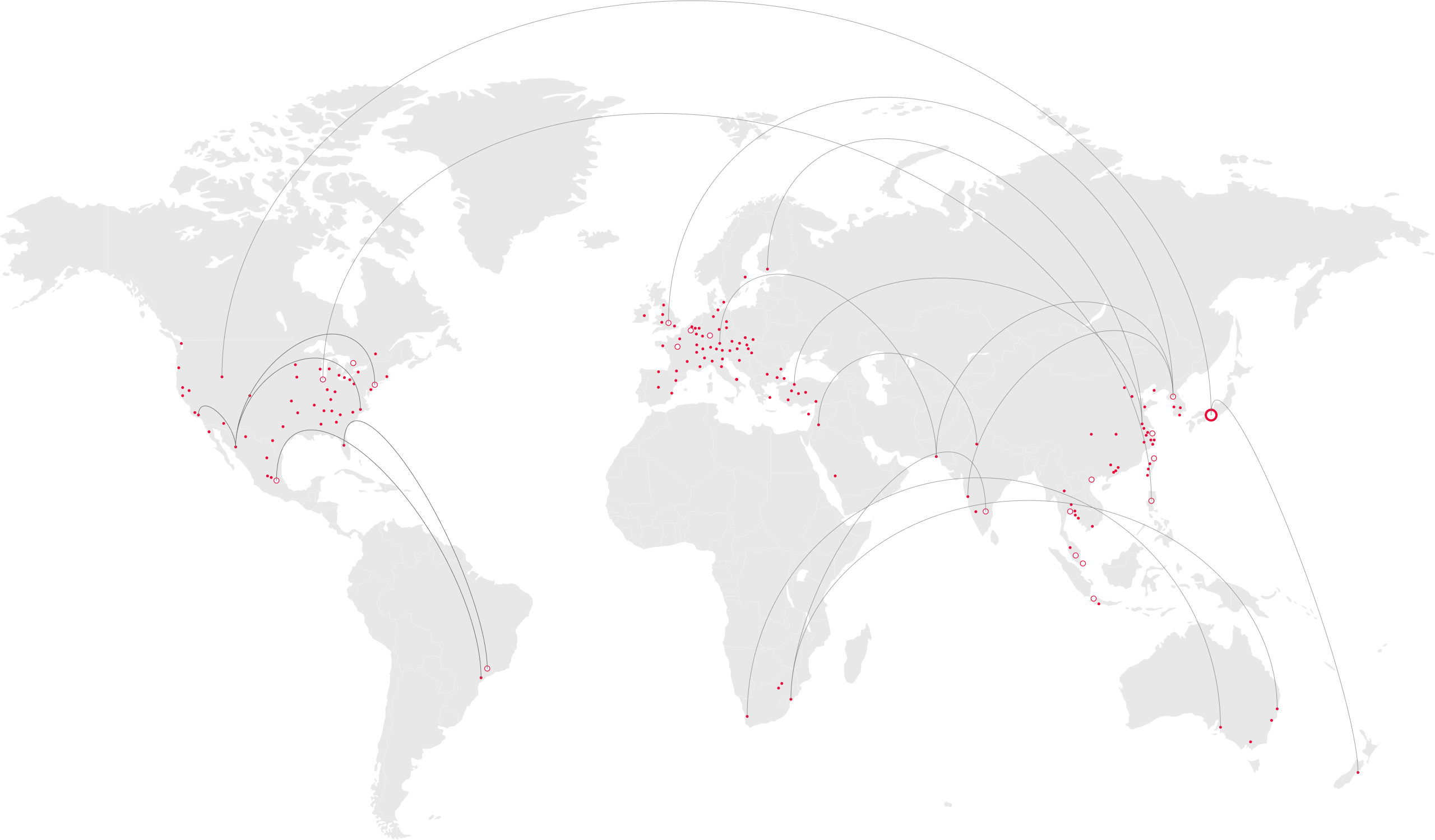

In order to present customers with unique products that are world or industry firsts, it is critical that sales personnel have a deep understanding of the products and applications. Thanks to our system that uses direct sales rather than distributors, our salespeople can propose appropriate and readyto-implement solutions using our products, based on a direct awareness of the problems and needs of the customer. And by building awareness of each customer’s potential needs, this can lead to the development of the next innovative product. Even for cross-border projects, our system, with sales representatives at 250 offices in 46 countries, makes it possible for us to provide global support for customers’ manufacturing.

Same-Day Shipping

We offer same-day shipping on our products, worldwide. This means that our customers don’t need to prepare extra stock to have what they need on hand, in the volume they need, when they need it. Customers can select the optimal product without worrying about different delivery dates for individual products, so they have more time to consider specifications. Roughly 70% of new products are world-first or industry-first, and our global direct sales allow us to accurately identify the potential needs of our customers, which enables the planning and development of products that become standard use in a wide range of industries. The fact that we don’t perform build-to-order manufacturing is another factor that allows us to offer same-day shipping

Global Support

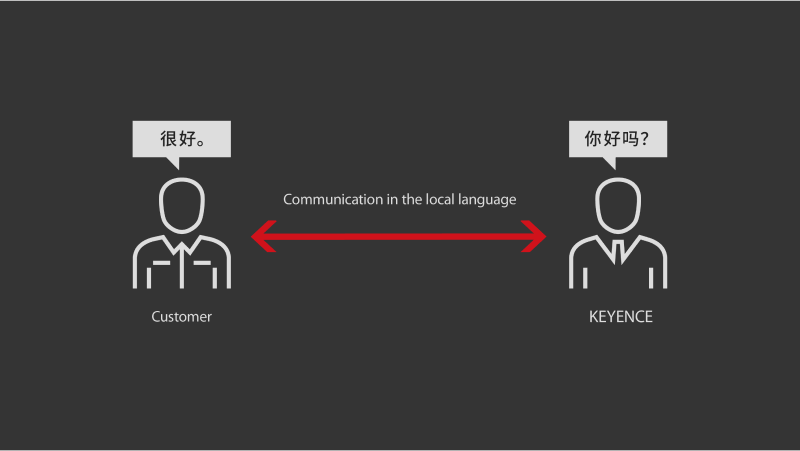

Providing the Same Direct Support all over the world

We believe that, in order to support global manufacturing, it is important to become a borderless company. To this end we have developed a system that allows us to provide high-quality service and support all over the world.

Training Programs for Local Staff

KEYENCE holds technical training seminars on the use of sensors, measurement instruments, and other topics for the local staff of our customers. By providing technical support based on the circumstances in each country, we deepen our connection to our customers.

We also have a wide range of manuals and technical guides translated into local languages.

Communication Handled by Local Staff

KEYENCE provides its local sales personnel overseas with the same level of technical training as in Japan. We perform sales activities that are rooted locally in each country.

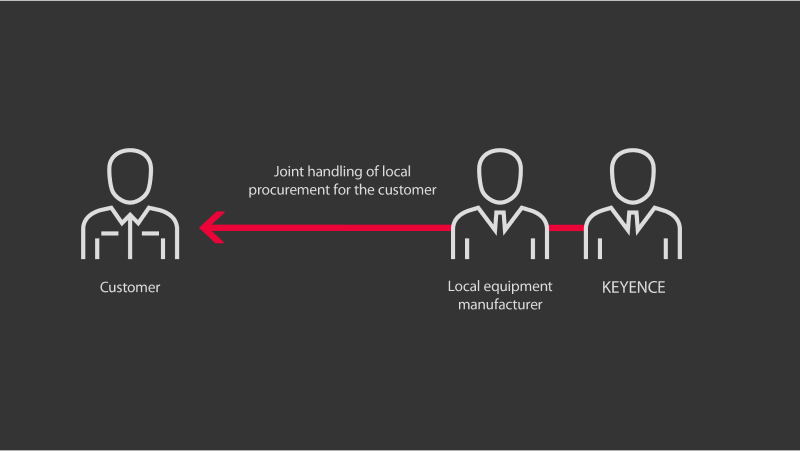

Collaboration with Local Equipment Manufacturers

For companies engaged in global manufacturing, a major challenge is local procurement of equipment and parts. At KEYENCE, we provide a service that introduces local manufacturers of various types of equipment. This supports the smooth installation of equipment, no matter where the site is located.

Further Expansion

Accelerated Global Expansion

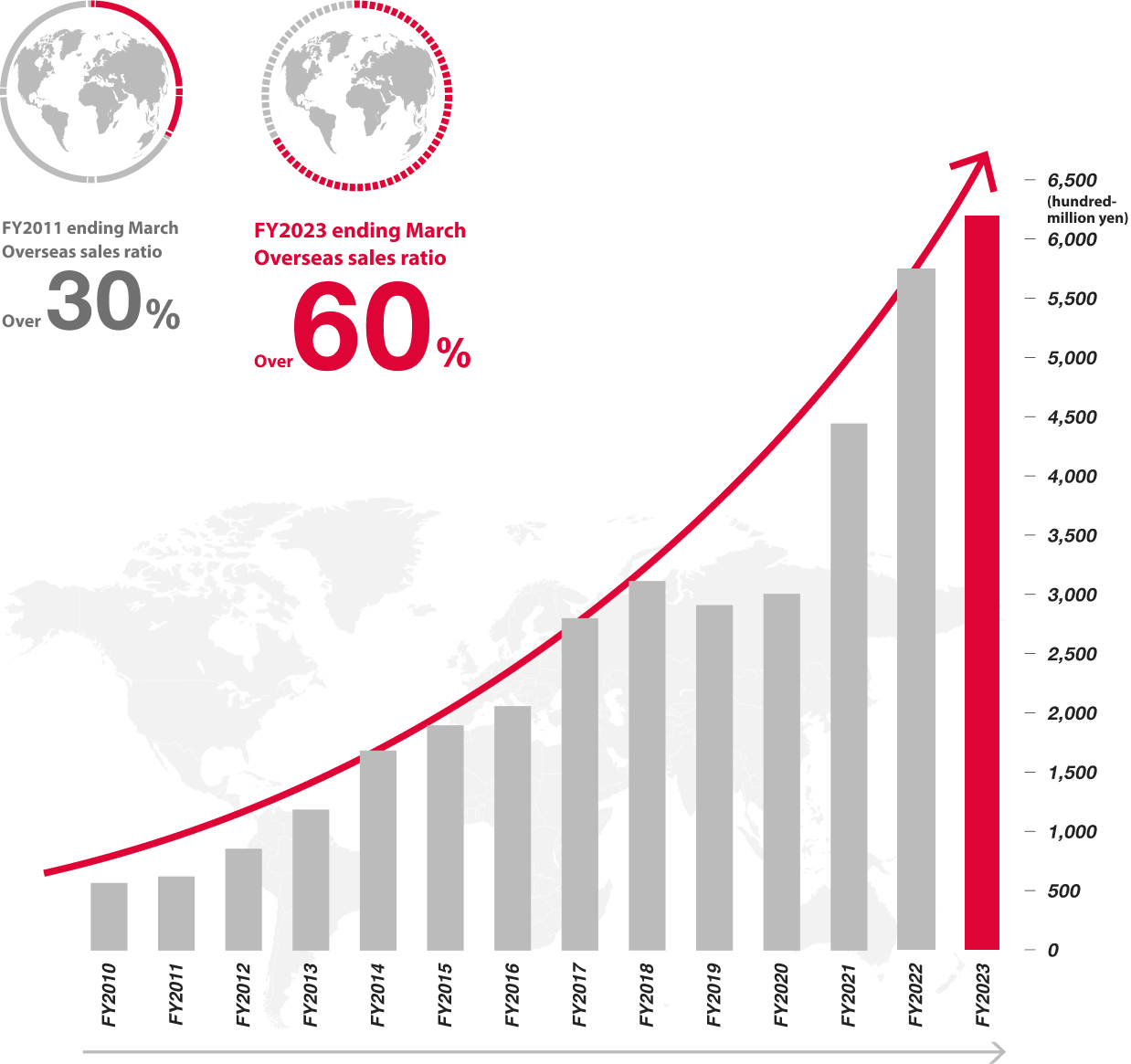

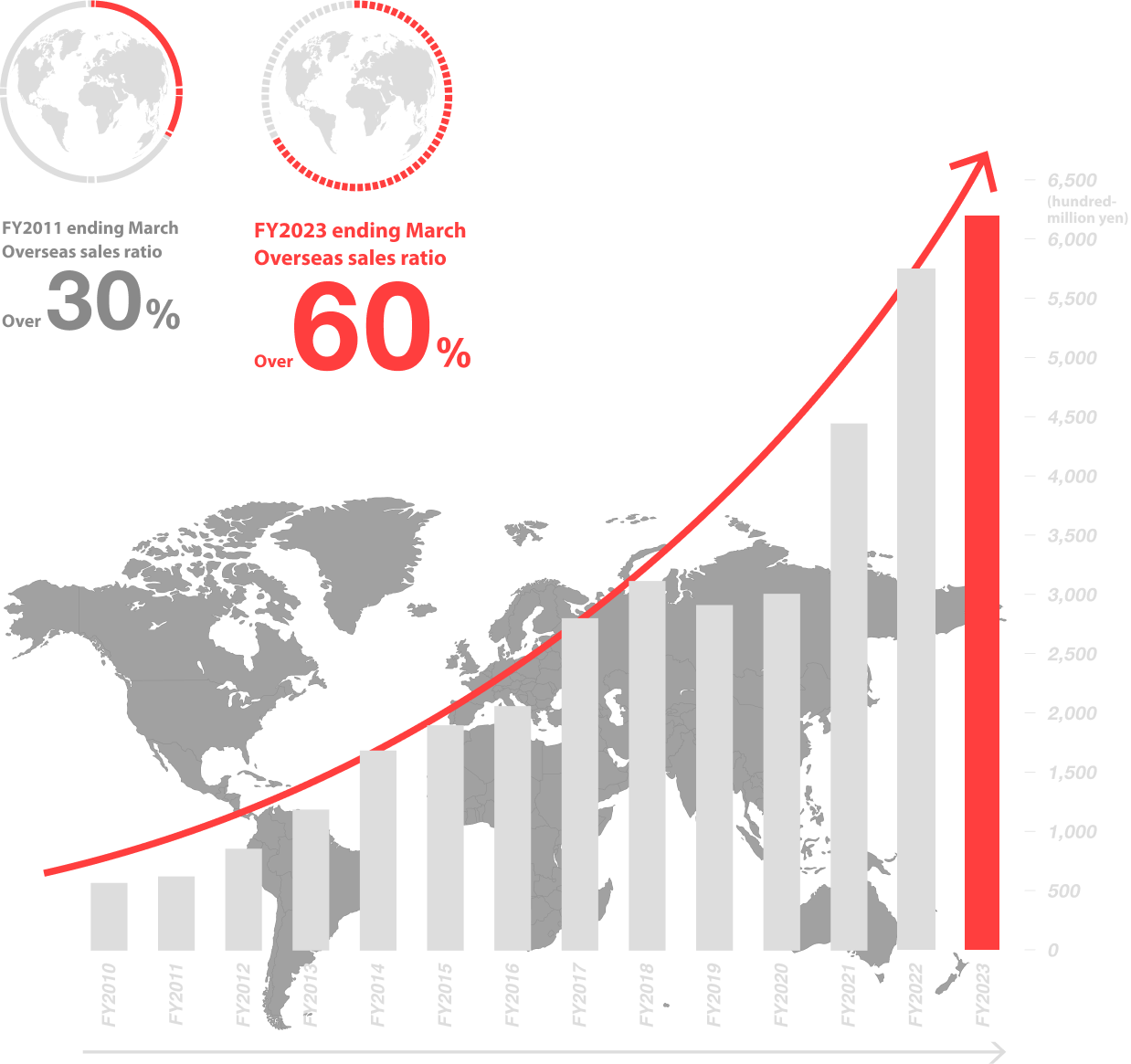

Thanks to the expansion of our global network, our sales in overseas markets have been continuously growing at an average rate of more than 15% over the past ten years, and overseas markets’ share of our overall sales has grown to more than 60%. When comparing the number of manufacturing sites between Japan and the rest of the world, the rest of the world naturally wins out by an incredibly large margin, so the overseas market still has huge potential for expansion. With the growth of developing economies, local manufacturing is also expanding, and the need for quality and safety will lead to greater investment in factory automation in the future. The focal point of KEYENCE’s business domain is truly the cutting edge of manufacturing. Through direct sales of a line of products that have high added value, we intend to continue supporting the development of manufacturing the world over.

Expansion of Business Fields

KEYENCE has utilized know-how and development strength cultivated in the factory automation market to expand our business in R&D, logistics, retail, and other fields. Going forward, we hope to develop more novel products to open up new markets, and to change the way the world works.

An all-in-one fluorescence microscope that contributes to research in biochemistry and medicine

A code reader that contributes to improved productivity at distribution centers

Handheld computers improve efficiency in any situation

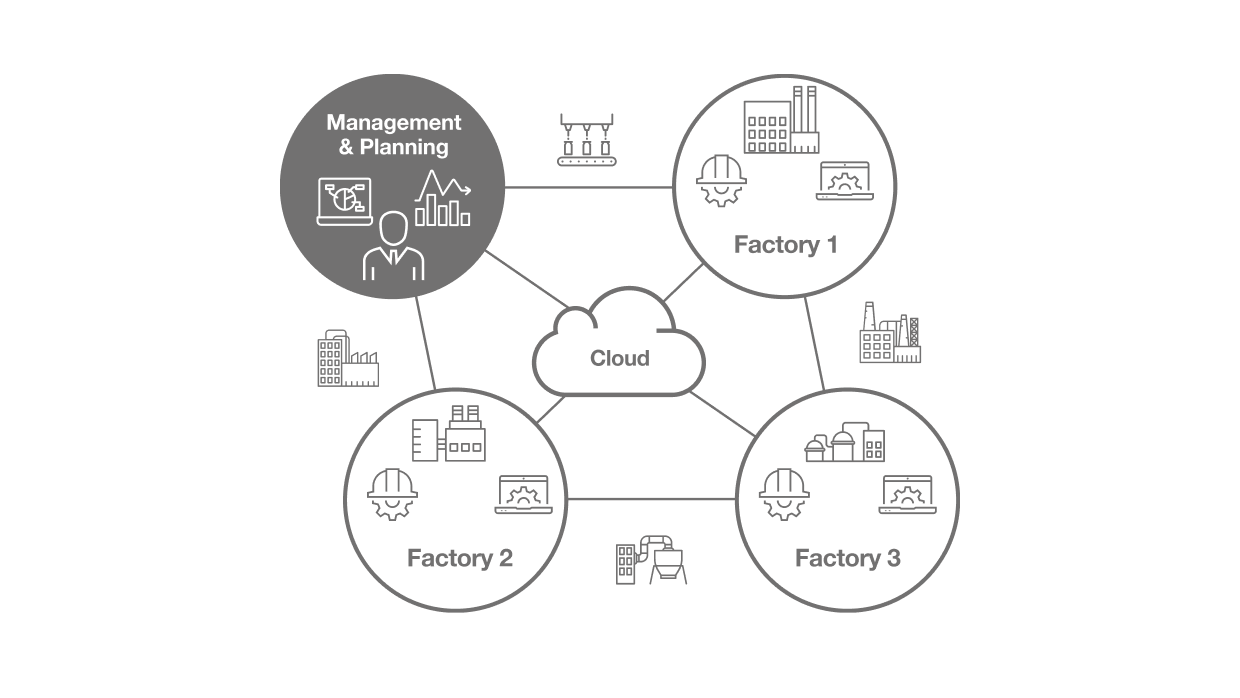

Accelerating Advances in Manufacturing

In addition to improving productivity and product quality at manufacturing sites, technological innovation is bringing about a variety of other reforms. Manufacturing is truly evolving on a global scale, whether it is electrification in the automotive industry, greater sophistication in smartphones, or the digital transformation (DX) that digital technology has promoted at production sites. By producing innovative products that predict potential needs, we are supporting the evolution of manufacturing.

DX is expected to massively improve productivity in the manufacturing industry going forward. Data utilization at factories starts with the connection of sensors and other devices to networks and collection of data. With the wide range of products KEYENCE offers, we will continue to contribute to the evolution of manufacturing sites brought about by the digital revolution.