Machine Vision System Selection GuideSelect your vision system according to your application

Case 1Detect surface features and defects, regardless of surface finish or appearance

LumiTraxTM lighting improves traditionally challenging inspections by extracting surface features and defects with the combination of directional lighting and high-speed cameras. This imaging technique is beneficial for low-contrast height features such as surface defects like chips or scratches, and it can be used on nearly any material or finish.

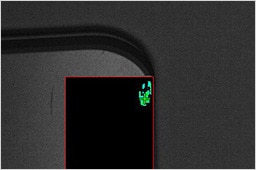

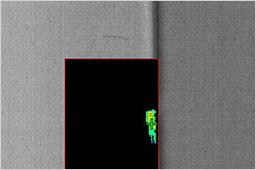

- Inspection of defects on a printed surface

- Create images to stably extract height defects without the influence of any printed text or patterns.

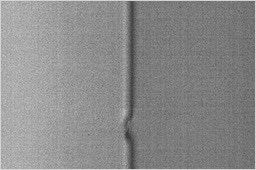

- Printed characters on film

- Eliminate glare on films to stably read text and barcodes.

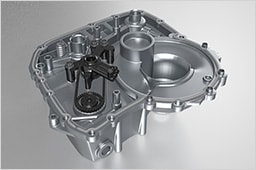

- Large part appearance inspection

- Inspect large, low-contrast parts such as engine blocks and wheels over areas of 15.75" x 15.75" and larger.

Solution

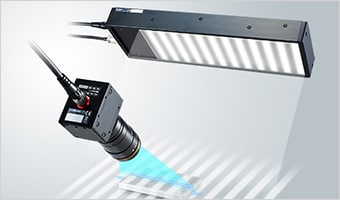

- High-Intensity LumiTraxTMLights

- Use directional lighting to create shadows for detection of height features and defects on the surface of parts. This lighting technique can also remove glare on shiny objects for stable inspection and reading.

Case 2Detect small defects that are difficult to see due to low contrast

Multi-Spectrum technology combines high-speed imaging with varying combinations of lighting from 8 different LED colors to generate greater contrast where traditional lighting cannot. Increased contrast allows for greater stability and precision in your inspection process.

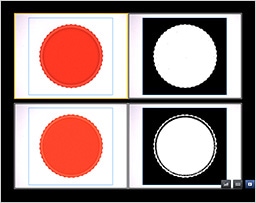

- Inspection of multiple product types (sorting and defect detection)

- Clearly distinguish between different parts, even when the difference is not easily seen.

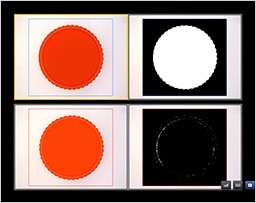

Conventional color camera

Multi-Spectrum Mode

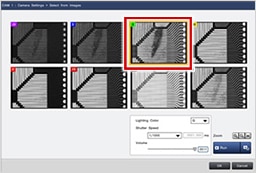

- Inspect multiple products with easy changeover

- Simple setup with guided selection to select the best lighting color to use for the current inspection

Choose the image that best highlights the defects

Stable detection is possible!

- Glossy part inspection

- With LumiTraxTM (highlighted in Case 1) included in the Multi-Spectrum Light, choose the optimal lighting color to eliminate glare on your parts.

Normal Image

White LED

Infrared LED

Solution

- Multi-Spectrum Lights

- Quickly and easily perform highly accurate color and defect detection with this award-winning combination of high-speed monochrome cameras and 8 color lighting.

Case 3Detect critical height features and confirm proper assembly

Imaging with Pattern Projection adds unparalleled stability and flexibility to a 2D vision system with the addition of 3D height data. For example, differentiating between a properly vs improperly seated part is often difficult with a standard 2D image; however, it is simple with Pattern Projection because height can be measured at any area in the image.

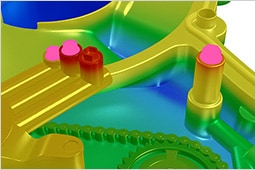

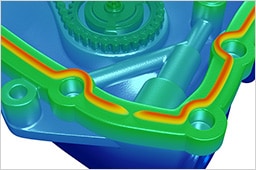

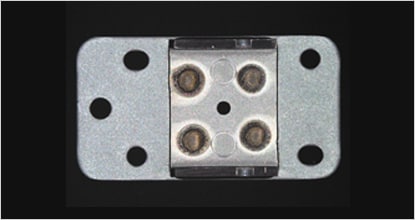

- Transmission assembly and sealant inspection

- A variety of 3D inspections tools make inspection for presence of features and defects possible, even when contrast is low.

Verify Component Assembly

Seal Height Measurement

- Lithium-ion battery inspection

- LumiTraxTM and Outline Capture Mode emphasize the position of low-contrast features for presence/absence and positioning. 3D imaging can detect proper height and assembly.

Profile Imaging Modes

3D Imaging Modes

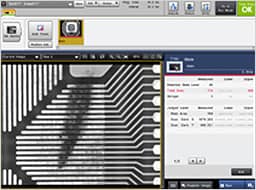

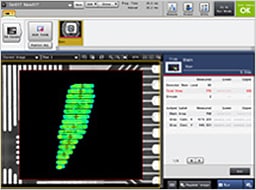

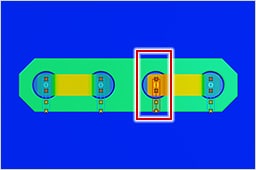

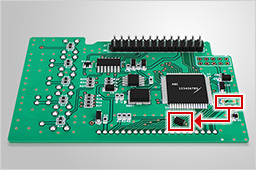

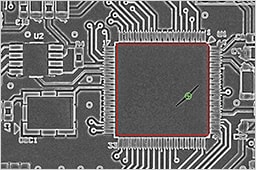

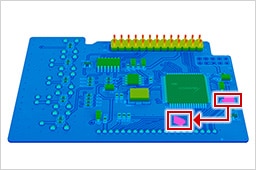

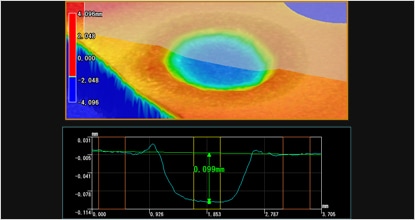

- Appearance of foreign particles and defects on PCBs

- Capture all height differences on PCBs and other complex parts with 3D comparison. LumiTraxTM helps to detect fine scratches and other surface defects.

LumiTraxTM Mode

3D Imaging Modes

Solution

- Pattern Projection Lights

- With multiple imaging modes, Pattern Projection lighting offers the most stable vision inspection in the industry. From 3D inspection to high-speed 2D imaging, the Pattern Projection Vision System offers the flexibility for all part inspection up to 10 inches (250mm).

Case 4Detect dents and scratches on large parts

Line scan LumiTraxTM merges high-speed, high-resolution line scan imaging with LumiTraxTM technology, making it possible to stably detect defects of all types on parts, regardless of surface finish (ranging from shiny metal to transparent) or size. Line scan imaging also makes it possible to inspect continuously moving targets.

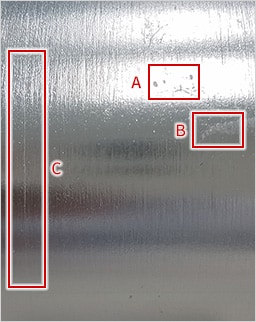

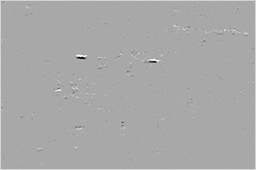

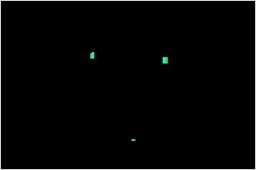

- Surface inspection of metal cylinders

- Stable detection of defects such as dirt, dents, and scratches on reflective metal products.

LumiTraxTM image

A: Pinholes and dents

Processed image

LumiTraxTM image

B: Finish defects

Processed image

LumiTraxTM image

C: Linear scratches

Processed image

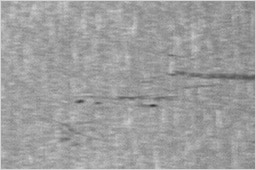

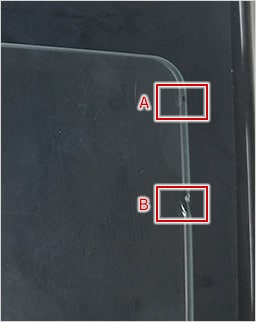

- Glass defect and dimension inspection

- Detect surface contamination and edge defects on transparent glass and plastic.

LumiTraxTM image

A: Contamination

Processed image

LumiTraxTM image

B: Flaws on edges

Processed image

- Dimension and appearance inspection of sheets and films

- Continuously inspect products over large areas without reflection or variable lighting at extremely high speeds.

Solution

- LumiTraxTM Specular Reflection Mode

- By incorporating LumiTraxTM into line scan cameras, it is now possible to extract surface defects at higher speeds while inspecting large parts with high-resolution. Create images on transparent, glossy, and matte targets with one vision system.

Case 5Perform accurate 2D/3D inspections and measurements, simultaneously

The XT 3D camera simultaneously captures color 2D & 3D images in 0.6 seconds with 1 micron repeatability. This in-line inspection and measurement system provides incredible speed, stability, and accuracy for parts that require high-resolution such as connectors, electronics, and medical parts.

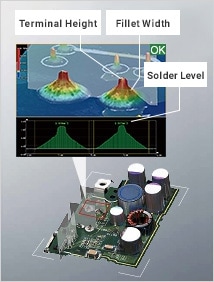

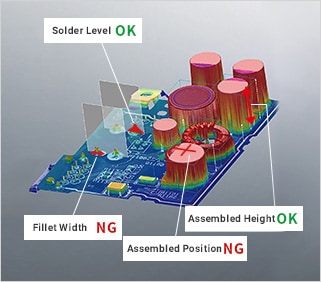

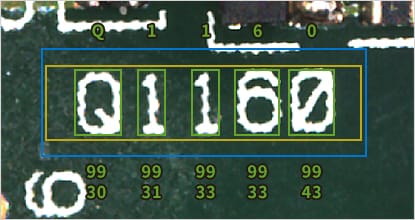

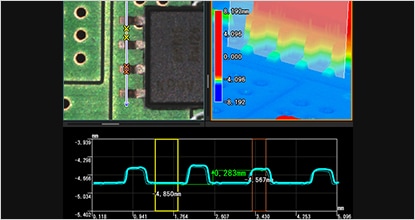

- 3D measurement and inspection of circuit board components and solder

- Perform height, volume, and position measurements with ease on small electronic components and solder joints. Use the 2D color image for additional inspections such as OCR and appearance inspection on the board.

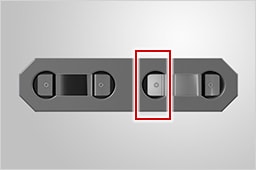

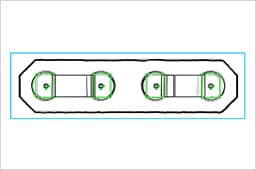

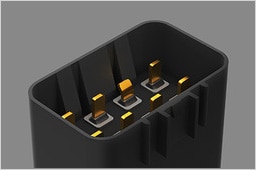

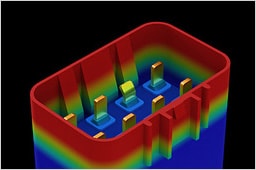

- Inspection of connector pins

- Measure coplanarity, pin pitch, and position of connector pins inside plastic housing. With built-in telecentric lensing and 4 projector lighting, measuring true pin position is possible without interference from connector housings.

- Weld measurement and inspection

- Measure welds with profile tools to detect height and position while using color images to detect for discoloration and cracks.

- Perform high-resolution 2D inspections

- Using the RGB lighting, the XT captures high-resolution color images for advanced 2D inspection. Standard camera inspections such as reading OCR and barcodes, detecting surface flaws, and measuring edges can be performed alongside 3D measurements.

Solution

- XT Series 3D Camera

- Perform 100% inspection with this high-resolution 3D camera for applications that require precision. With over 9MP resolution, telecentric lensing, and 4 RGB projectors, capture all data in the field of view with no distortion or 3D drop out.