Double Blank Sheet Detection

Sensors are used during the transferring of blank sheets to detect, from the side of the target, whether two sheets have been transferred by mistake, helping to improve the yield in later processes.

This page introduces vision sensor applications in the metals industry.

Sensors are used during the transferring of blank sheets to detect, from the side of the target, whether two sheets have been transferred by mistake, helping to improve the yield in later processes.

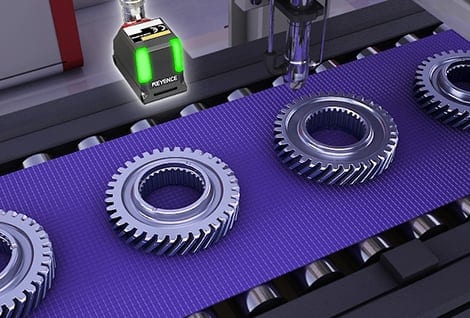

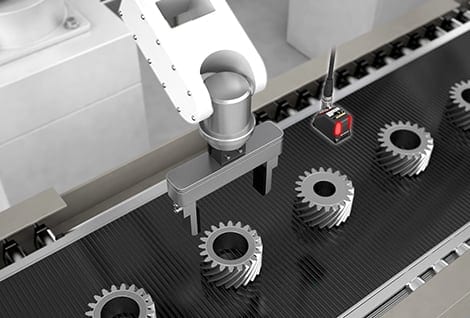

Sensors are used to detect whether the gears that are transferred on the conveyor belt are oriented correctly (front/back), helping to improve the yield in later processes.

Sensors are used to perform product type detections according to differences between the inner diameters of the gears, helping to implement countermeasures against the mixing of incorrect products on lines where multiple product types are handled at the same time.

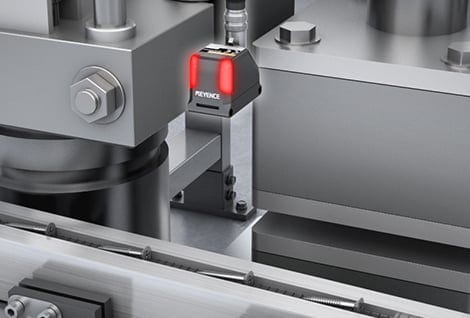

Sensors are used to differentiate between the front and back of metal parts by detecting differences in the amount of reflected light, helping to eliminate mistakes.

Sensors are used in the screw transportation process to detect the screws that have been processed.