3D Shape and Appearance Inspection

The shape of the target is captured in 3D for measurement and inspection. Various laser-based methods—point, line, and surface—are available for different applications. Depending on inspection conditions and targets, the appropriate method may differ. Check out some typical methods below, or request a free consultation with a measurement expert.

2D Profilers can measure width, height, and volume of sealant beads inline, regardless of surface finish or color.

2D/3D Laser Profiler

LJ-X8000 series

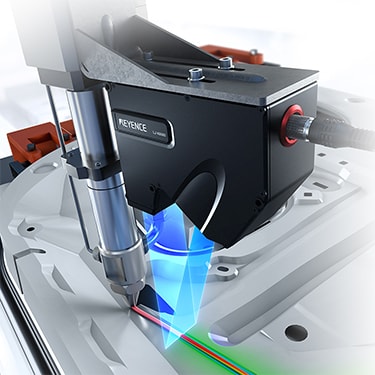

Unlike triangulation sensors, interferometers can measure small parts in confined spaces without blind spots or unstable data.

3D Interference Measurement Sensor

WI-5000 series

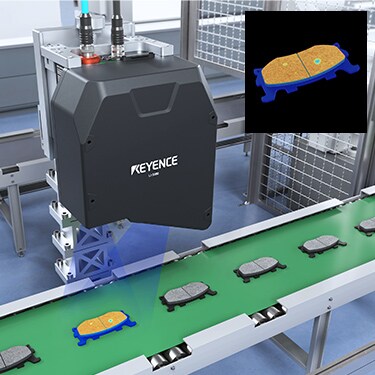

Height images can be used for appearance inspections of defects such as brake pad surface scratches and dents. Uneven surfaces, etc., can be detected regardless of features such as markings and patterns on the target surface.

3D Laser Snapshot Sensor

LJ-S8000 series

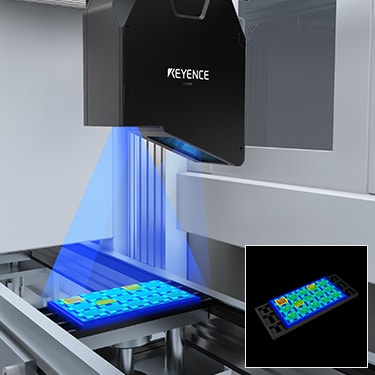

The automatic scanning mechanism of the sensor head captures the entire surface of the tray, allowing for simultaneous acquisition of the height information and grayscale information. Consequently, various inspections including OCR, 2D code reading, chip seating, chip presence, and chip counting can all be performed at the same time.

3D Laser Snapshot Sensor

LJ-S8000 series

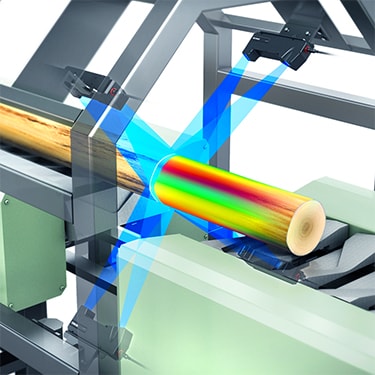

Profile measurement can be continuously performed on captured 3D shapes. This allows pass/fail criteria to be applied to maximum and minimum values over an area or period of time, making it possible to catch small defects in continuous processes.

2D/3D Laser Profiler

LJ-X8000 series

Free-form planes allow the system to pick up on deviations from the typical contour of a surface.This makes stable defect detection possible, even for targets with complex shapes.

2D/3D Laser Profiler

LJ-X8000 series

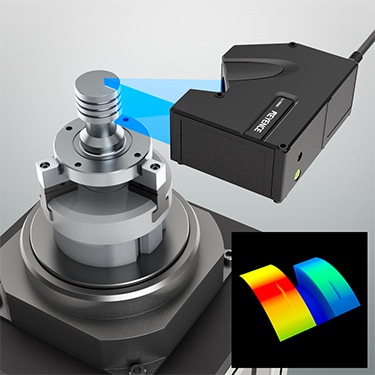

Highly accurate measurements can be made even when measuring targets with height differences or where the distance from the target to the sensor could vary.

2D/3D Laser Profiler

LJ-X8000 series

Conventional grayscale images did not allow for stable appearance inspections of targets with varying surface colors and luster such as welding beads. However, 3D appearance inspections that use height measurement data make it possible to detect uneven surfaces and other conditions regardless of target surface features.

3D Laser Snapshot Sensor

LJ-S8000 series

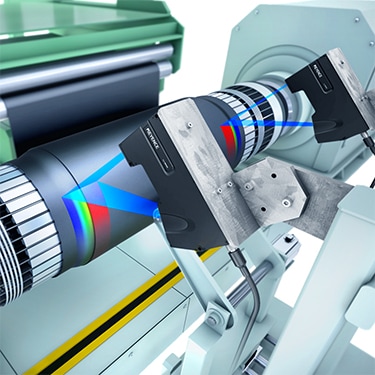

Targets with multiple materials can be captured in a single profile, allowing measurements to be made between glass and metal surfaces. The LJ-X Series is equipped to handle reflectances ten times higher than conventional products.

2D/3D Laser Profiler

LJ-X8000 series

For targets with different diameters, conventional vision systems often have a hard time focusing on the larger and smaller diameter areas at the same time. Measuring the height of the dents with a laser profiler makes it possible to inspect the whole surface at once.

2D/3D Laser Profiler

LJ-X8000 series

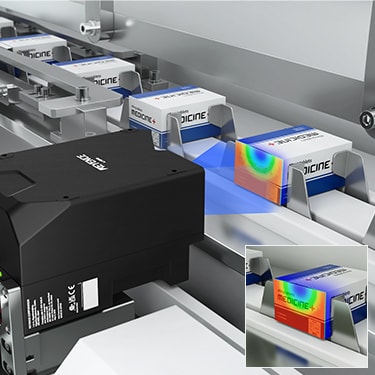

Cases of food and medicine are inspected to see if they are crushed. These inspections use height images created from the measured height of the target surface, making it possible to detect uneven surfaces and other conditions regardless of markings, patterns, or other target surface features.

3D Laser Snapshot Sensor

LJ-S8000 series

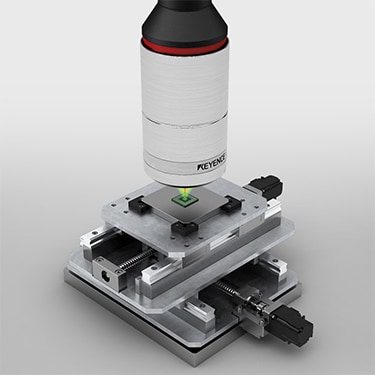

A displacement sensor with an extremely small beam spot of just 3.5 µm can be used for accurate profile measurements of roughness and minute shapes. 3D shape measurements are also possible through detailed scanning synchronized with an X-Y stage. Measurements with impressive angle characteristics are possible not only for opaque targets but also transparent targets and 3D shapes with mirrored surfaces.

Confocal Displacement Sensor

CL-3000 series

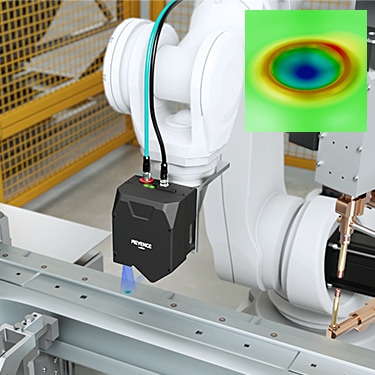

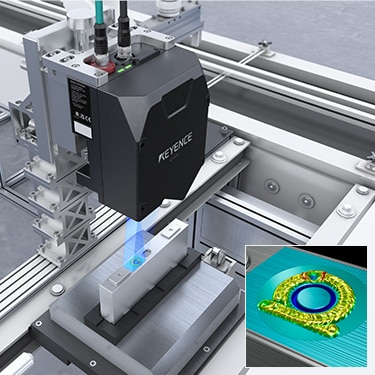

The shape and appearance of spot welds can be inspected. The sensor head can be mounted on a robot allowing for inspections from various angles and of diverse locations. Furthermore, the built-in scanning function enables stable inspection with no need to worry about robot vibration or linearity.

3D Laser Snapshot Sensor

LJ-S8000 series