Risk Assessment

Risk Assessment Process

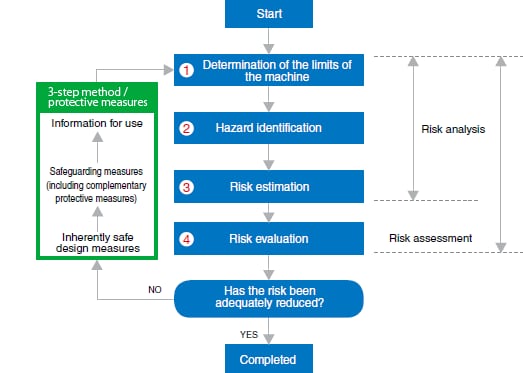

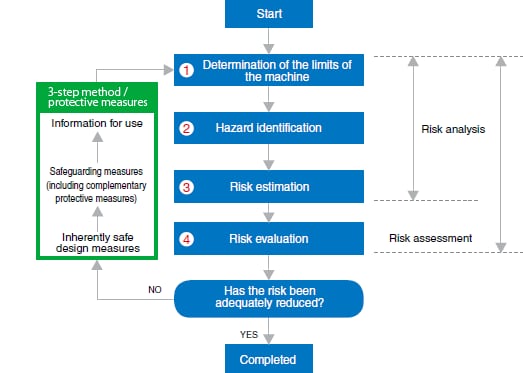

The following flowchart shows the risk assessment process established by ISO 12100.

- 1.Determination of the limits of the

machinery

- Risk assessment begins with the determination of the limits of the machinery, taking into account all the phases of the machinery life.

This means that the characteristics and performances of the machine or a series of machines in an integrated process, and the related people, environment, and products, should be identified in terms of the limits of machinery.

- 2.Hazard identification

- After determination of the limits of the machinery, the essential step in any risk assessment of the machinery is the systematic identification of reasonably foreseeable hazards (permanent hazards and those which

can appear unexpectedly), hazardous situations and/or hazardous events during all phases of the machine life cycle.

- 3.Risk estimation

- After hazard identification, risk estimation must be carried out for each hazardous situation by determining the elements of risk. When

determining these elements, it is necessary to take into account the aspects, such as persons, duration of exposure, suitability of protective measure ...etc.

- 4.Risk evaluation

- After risk estimation has been completed, risk evaluation must be carried out to determine if risk reduction is required. If risk reduction is required, then appropriate protective measures must be selected and applied.

- What are use limits?

- Use limits include the intended use and the reasonably foreseeable misuse.

- What are space limits?

- Space limits include the range of movement or human interaction such as the operator-machine interface.

- What are time limits?

- Time limits include the life limit of the machinery and/or of some of its components.

- What is hazard identification?

- This is an identification of potential source of harm. The hazard either is permanently present during the intended use of the machine, or can appear unexpectedly.

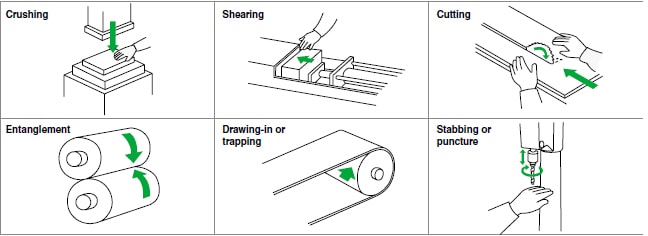

- Hazard identification

-

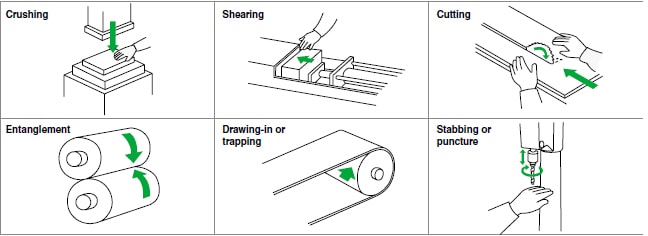

- Mechanical hazards

- Other hazards

- Electrical hazards, thermal hazards, hazards generated by noise, hazards generated by vibration, hazards generated by radiation, hazards generated by materials and substances, hazards generated by ignoring ergonomic principles, etc.

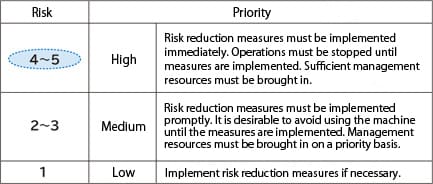

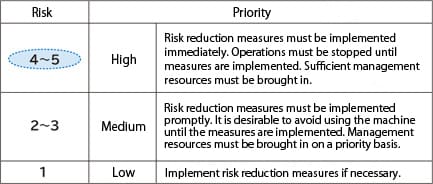

- Estimating

-

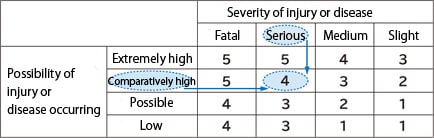

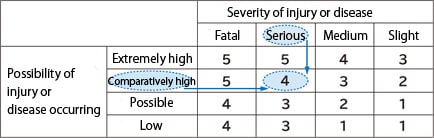

- Example 1: Using a matrix

Example of an estimate with a severity value of “(2) Serious” and a possibility value of “(2) Comparatively high”