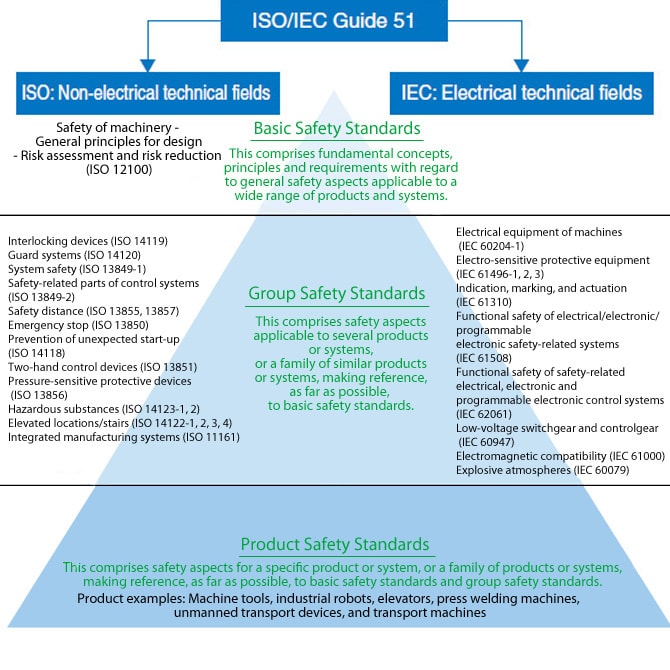

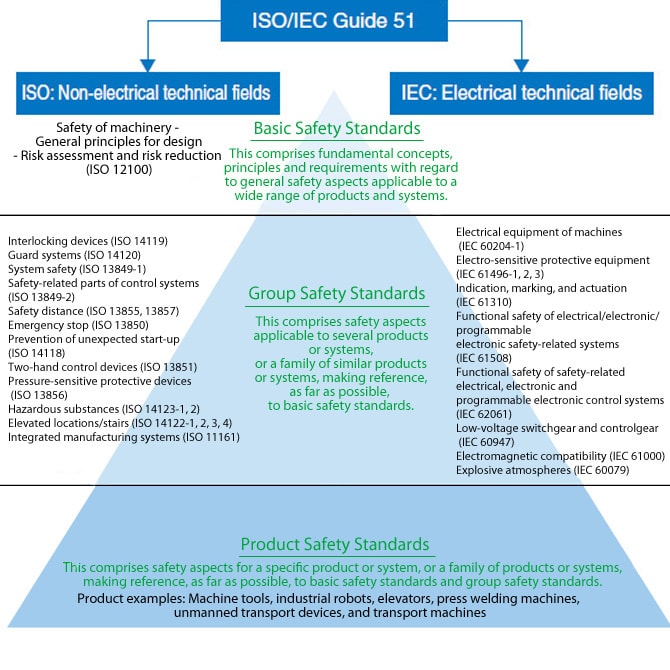

Organizational Diagram of Safety Standards

International Standards of Machine Safety

There is no guarantee that an ISO or IEC standard will exist for a given machine. Realistically speaking, it is not possible to update standard requirements to match products as they evolve day by day. Therefore, ISO and IEC standards are separated into levels (by way of ISO/IEC Guide 51), and the latest machines are supported by using combinations of these standards.

International Standards of Machine Safety, ISO/IEC Standards

- ISO

- This is the International Organization for Standardization.The ISO is a standardization body established in 1947 that specializes in non-electrical technical fields. Their headquarters are located in Geneva, Switzerland. Some of the most well-known ISO standards include ISO 9001: Quality management systems and ISO 14001: Environmental management systems.

- IEC

- This is the International Electrotechnical Commission. The IEC is a standardization body established in 1908 that specializes in electrical and electronic technical fields. They are located in Geneva, Switzerland.

Principal Safety Standards [Glossary]

- ISO/IEC Guide 51

- This Guide provides requirements and recommendations for the drafters of standards for the inclusion of safety aspects in standards. It is applicable to any safety aspect related to people, property or the environment, or to a combination of these. The definition of “safety” is in this document, which means freedom from risk which is not tolerable.

- ISO 12100

- This is a basic safety standard for safety of machinery, which specifies principles of risk assessment and risk reduction, such as the 3-step Method, to help designers achieve safety in the design of machinery. The 3-step Method is a procedure for risk reduction, consisting of: 1) Inherently safe design measures, 2) Safeguarding and/or complementary protective measures, and 3) Information for use. In 2010, former basic standards, ISO 12100-1: 2003 and ISO 12100-2: 2003, were integrated in ISO 12100: 2010 without any changes on technical standpoint.

- ISO 13849-1

- This safety standard provides safety requirements and guidance on the principles for the design and integration of safety-related parts of a control system. This defines the performance level (PL), which is the discrete level used to specify the ability of safety-related parts of control systems to perform a safety function.

- ISO 14121-1

- This safety standard had provided general principles intended to be used to meet the risk reduction objectives established in ISO 12100-1: 2003. In 2010, this standard was also integrated in ISO 12100: 2010 without any changes on technical standpoint.

- IEC 60204-1

- This safety standard applies to the application of electrical, electronic and programmable electronic equipment and systems to machine not portable by hand while working, including a group of machines working together in a co-ordinated manner.