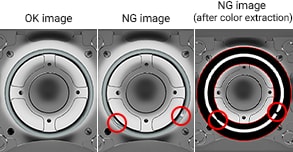

Key inspection points

Detect orientation, alignment, and defects on motors and batteries for electric vehicles with high-resolution cameras.

Verifies and outputs the coordinates (XY) and angle of targets for positioning and alignment applications.

Electric Vehicle Components

Detect orientation, alignment, and defects on motors and batteries for electric vehicles with high-resolution cameras.

Multi-Spectrum Vision System

CV-X/XG-X Series

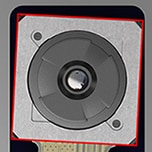

ADAS Components

Confirm orientation and position of automonous vehicle parts including cameras and sensors.

Intuitive Vision System

CV-X Series

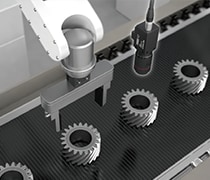

2D Vision Guided Robotics

Utilize automatic robot calibration to quickly setup robotic pick and place applications.

Quick and Easy to Deploy 2D VGR

CV-X/XG-X Series

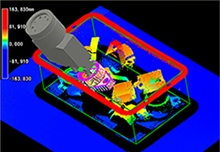

3D Vision Guided Robotics

An impressive 3D camera, easy-to-use system, and robotic path planning combine for the industry's most stable and capable bin picking solution.

Quick and Easy to Deploy 3D VGR

CV-X Series