Projection welding

Projection welding is often used to manufacture weld nuts and weld bolts. This page introduces projection welding, a method that adopts resistance welding principles. This method is broadly divided into two types: embossed projection welding and solid projection welding.

This method is used for welding nuts/bolts to steel plates. Electrodes for resistant spot welding are applied to the projection(s) provided on one of the base materials. Heat is concentrated on the projection(s) to soften the material and the welding starts. As the welding proceeds, the spot(s) becomes larger. Although this decreases the current density, the electrical resistance is increased by the raised temperature, which maintains high heat generation to allow welding. Consequently, the weld has high quality as compared to welding without using projections.

Projection welding is broadly divided into two types: Embossed projection welding and solid projection welding.

Embossed projection welding uses projections worked on the base material to concentrate current flow on the projections. Creating multiple projections allow simultaneous welding of multiple weld spots. Practical applications include welding gas tank reinforcements, shock absorber brackets, and oil filters. Unlike embossed projection welding, solid projection welding does not use projections created on a flat plate. It uses existing projections such as the corners of plates or crossed round bars. Practical applications include welding nuts and bolts on plates, or brake drums.

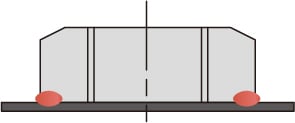

- Embossed projection welding

-

Before welding

After welding

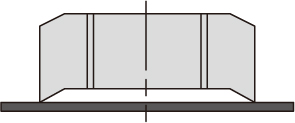

- Solid projection welding

-

Before welding

After welding