Internal defects that impair welding quality

Molten metal-based joining may produce defects inside the weld due to phenomena specific to welding.

As with surface defects, these internal defects affect the welding strength and quality.

This page introduces typical internal defects that impair welding strength and quality.

- Blow holes

- Impure compound

- Slag inclusion

- Incomplete penetration

- Incomplete fusion

- Internal cracking

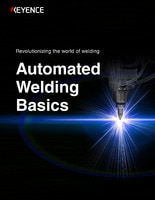

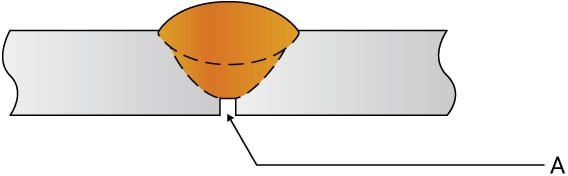

Blow holes

This defect is produced when the gas that could not escape before the solidification of molten metal collects to form spherical cavities inside the bead. If these gas cavities solidified on the bead surface and left holes, they become the surface defect known as pits (open defect).

- Blow holes

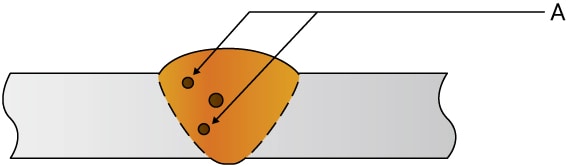

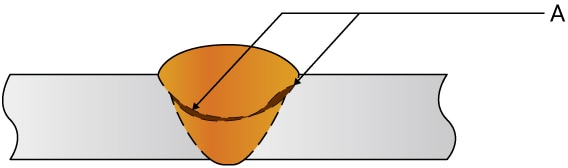

Impure compound

This defect is produced when gas molecules are trapped inside the molten metal and bond with the base material to create impure compounds that remain inside the bead.

- Impure compound

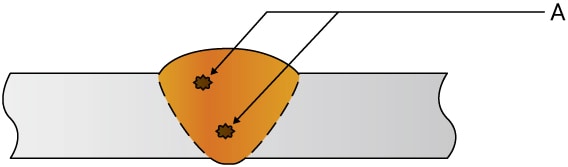

Slag inclusion

This defect is produced when slag generated during welding solidifies faster than the solidification of the molten metal and remains within the molten metal.

- Slag inclusion

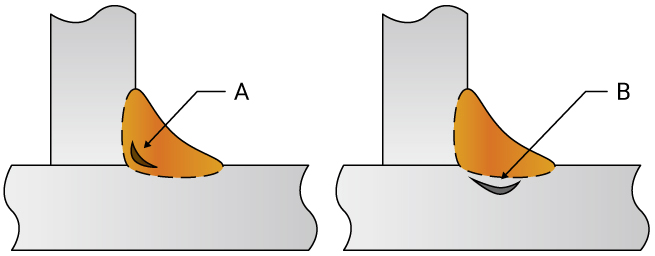

Incomplete penetration

This defect forms when the penetration is less than the desired position or depth due to insufficient heat input to the molten metal or other causes.

- Incomplete penetration

Incomplete fusion

This defect is produced when the process cannot properly melt the bead in a lower layer penetrated earlier (previous layer bead) due to insufficient heat input to the molten metal.

- Incomplete fusion

Internal cracking

Internal cracking forms cracks inside the weld. Typical cracking types classified as internal defects are weld metal cracking (root cracking) and heat-affected-zone (HAZ) cracking (underbead cracking). Weld metal cracking is a defect produced inside the molten metal. HAZ cracking is a defect produced when the weld cools quickly which makes the base material brittle, resulting in cracks caused by the contraction force of the already solidified section.

- Root cracking

- Underbead cracking