Film / Sheet

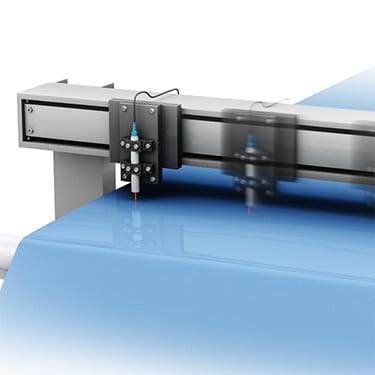

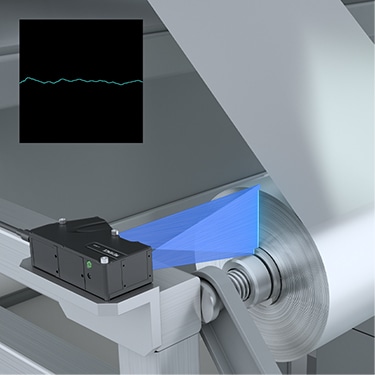

Measure transparent film immediately after coating using the SI Series. By traversing the sensor, you can get real-time process feedback across the width of the web to improve overall quality while minimizing waste.

Micro-head Spectral-interference Laser Displacement Meter

SI-F series

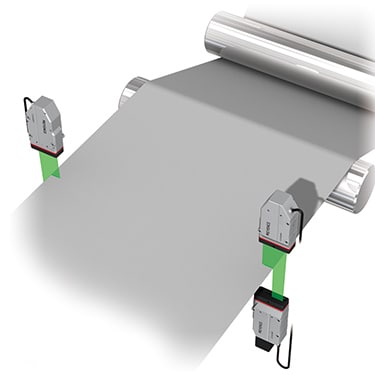

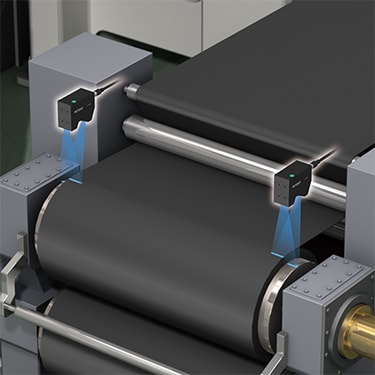

Measure width and meandering with a single setup. Placing an optical micrometer on each end of the web provides a great low maintenance solution thanks to their high speed and accuracy.

High-speed optical micrometer

LS-9000 series

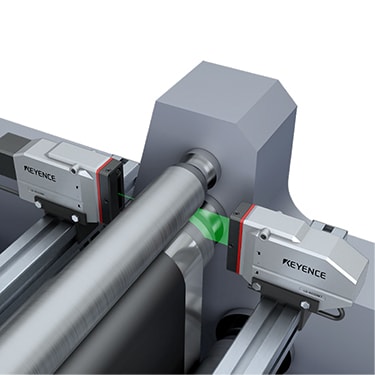

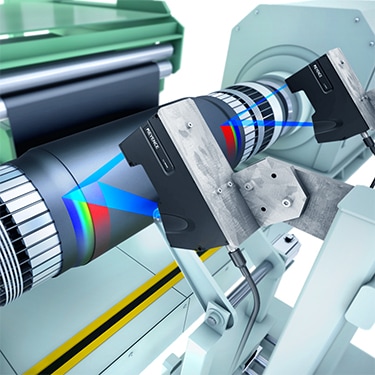

By monitoring the gap between coating rollers at one or both ends, it's possible to maintain tight control over sheet thickness. The LS-9000 Series can measure gaps as small as 10μm, so this solution works for even extremely thin films.

High-speed optical micrometer

LS-9000 series

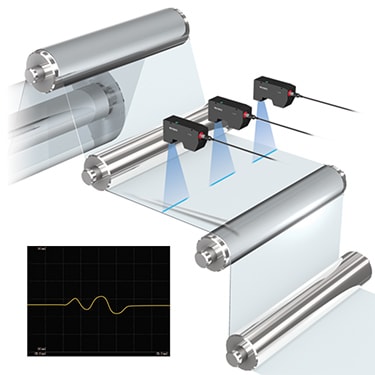

Using non-contact sensors makes it simple to get 100% inspection for sheet thickness. The CL-3000 can measure thickness of any material, regardless of color or surface finish, without having to adjust the settings.

Confocal Displacement Sensor

CL-3000 series

By profiling the entire surface of a film, it's possible to reliably detect wrinkles. Laser profilers provide a great alternative to cameras here because you can rely on height changes in addition to contrast changes to pick up on defects.

2D/3D Laser Profiler

LJ-X8000 series

2D Laser Profilers can inspect the end profile of a roll as the sheet is wound to prevent telescoping/dishing. With in-process inspection, issues like wrinkles and meandering during unwinding can be avoided, leading to overall improved efficiency.

2D/3D Laser Profiler

LJ-X8000 series

Measure the width and thickness of rubber sheets with a single system. By using a laser profiler on each edge of the sheet, you can monitor the height difference between the roll and the material to get thickness and edge profile, in addition to sheet width.

2D/3D Laser Profiler

LJ-X8000 series

Complete 3D inspection of belt surfaces for small irregularities or foreign matter to prevent quality issues. The WI-3000 is a 3D displacement sensor that can quantify these defects to help inform preventative maintenance decisions.

3D Interference Measurement Sensor

WI-5000 series

Free-form planes allow the system to pick up on deviations from the typical contour of a surface.This makes stable defect detection possible, even for targets with complex shapes.

2D/3D Laser Profiler

LJ-X8000 series

![Automated Measurement and Inspection Examples [Films and Sheets]](/img/asset/AS_118777_S.jpg)