Outer / Inner Diameter

Outer diameter measurements can be performed at a single position, in multiple axes, or across an area to understand ovality and min/max OD. Similarly, there are varying levels of inspection available for inner diameter. You can browse the most common methods for measuring OD and ID below, or feel free to request a consultation with a local measurement expert.

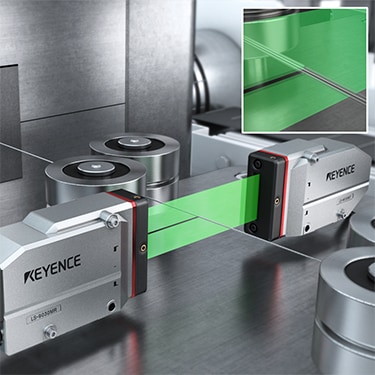

Thrubeam micrometers allow for high-speed measurement of wire OD without being affected by vibration.

High-speed optical micrometer

LS-9000 series

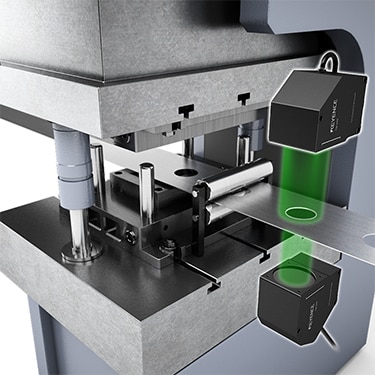

2D thrubeam sensors can measure hole diameter after stamping inline.

Telecentric Measurement System

TM-X5000 series

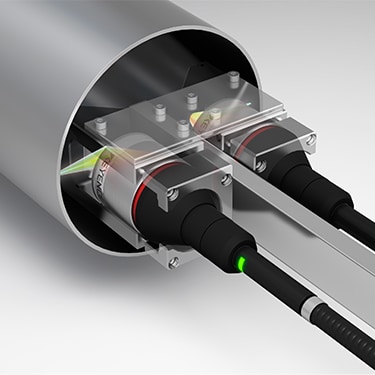

Non-contact measurement of the inner diameter of pipes is possible. Using a side view attachment allows for non-contact measurement even in locations with limited space for installation.

Confocal Displacement Sensor

CL-3000 series

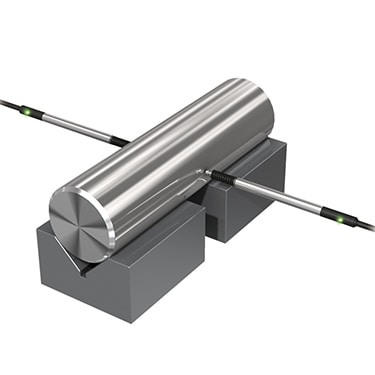

Check outer diameter on machined parts without influence from oil or other surface contamination.

High-Accuracy Digital Contact Sensor

GT2 series

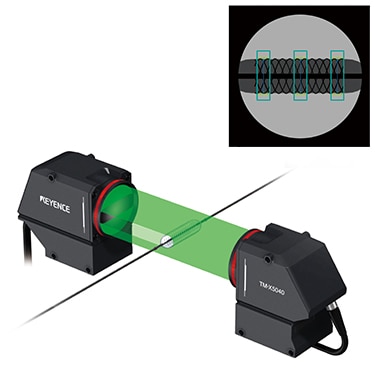

The outer diameter of a stent is measured in a non-contact manner. The TM-X Series automatically extracts the peak and bottom points of arbitrary areas, enabling the instant measurement of the maximum outer diameter, which was not possible with conventional outer diameter measuring instruments.

Telecentric Measurement System

TM-X5000 series

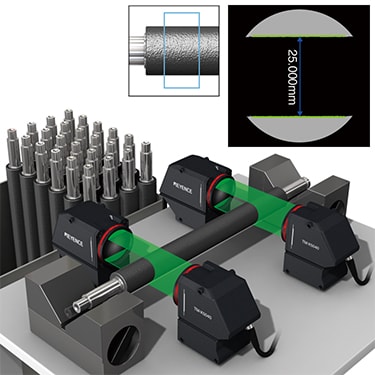

Compressible or rough surfaces can be accurately measured using the 2D image generated by the Telecentric Measurement System. Implementing non-contact measurement eliminates error due to part deformation and any variation in diameter due to surface texture can be averaged over to stabilize results.

Telecentric Measurement System

TM-X5000 series

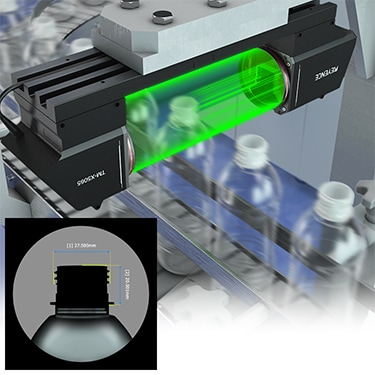

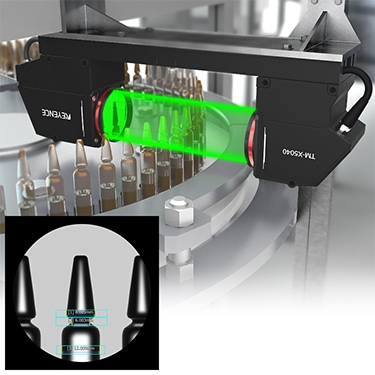

Using 2D measurement systems makes it possible to measure the minimum and maximum diameter on a target from a single captured image. The TM-X Series works by capturing the silhouette of a target using a telecentric optical system, so it can accurately measure objects of any material (including clear vials).

Telecentric Measurement System

TM-X5000 series

With an exposure time of just 100 µs, the Telecentric Measurement System can capture clear images of targets moving at high speed. This makes it an ideal solution for accurately measuring diameter inline.

Telecentric Measurement System

TM-X5000 series