What is Surface Roughness?

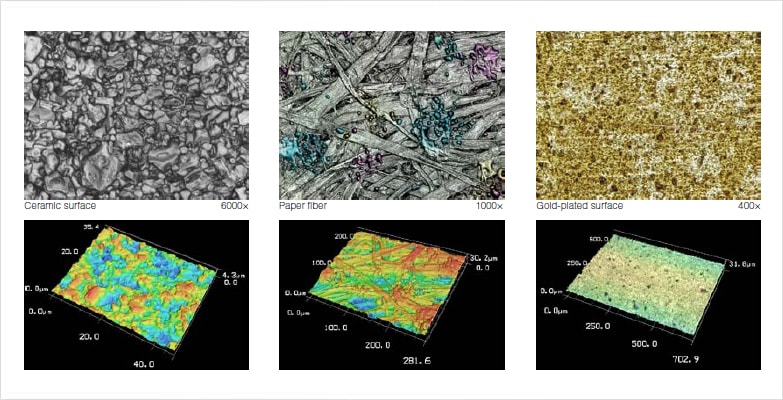

If you look at machined parts, you will notice that their surfaces embody a complex shape made of a series of peaks and troughs of varying heights, depths, and spacings. Surface roughness is defined as the shorter frequency of real surfaces relative to the troughs.

A product's exterior cover or appearance (specifically the differences in appearance, whether something is shiny and smooth or rough and matte), whether it's a vehicle's dashboard or a machined part, is due to the difference in its surface roughness.

Surface roughness not only affects the object's appearance, but it also produces texture and tactile differences. Appearance and texture can influence a product's added value in terms of customer perceived value and satisfaction.

If a part makes contact with another surface, its surface roughness affects the amount of wear or the ability to form a seal. If the part is to be painted, the roughness also affects the thickness of the paint. In recent years, it has therefore been required to quantify the asperity of a surface.

ISO 25178 Surface Texture

ISO 25178 Surface Texture is a collection of international standards relating to the analysis of surface roughness.

While JIS B 0671-1 and ISO 13565-1 (Surface Texture: Profile Method) are based on analysis using the stylus method, ISO 25178 standards support two evaluation methods: contact-types (stylus method) and non-contact types (optical probe)

This dual-method approach resolves existing problems in obtaining data using styluses: variations in measurement results that depend on the measurement site and variatoins due to the scanning direction.