Instantaneous Measurement of Medical Devices

-

Tags:

- Medical Devices

Many medical devices are used directly on patients, so ensuring a high level of quality, safety, and efficacy is essential. Rapid medical technological innovations and steady product improvements also mean frequent evaluations and inspections are necessary. Performing evaluations and testing large numbers of samples automatically and accurately under the same conditions can save a great deal of time. This section introduces various medical technologies and devices along with example inspections using KEYENCE's 3D Surface Profiler.

We’re here to provide you with more details.

Reach out today!

Injection Needles

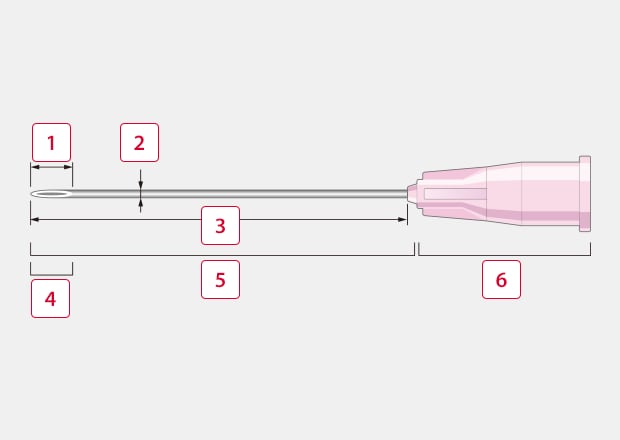

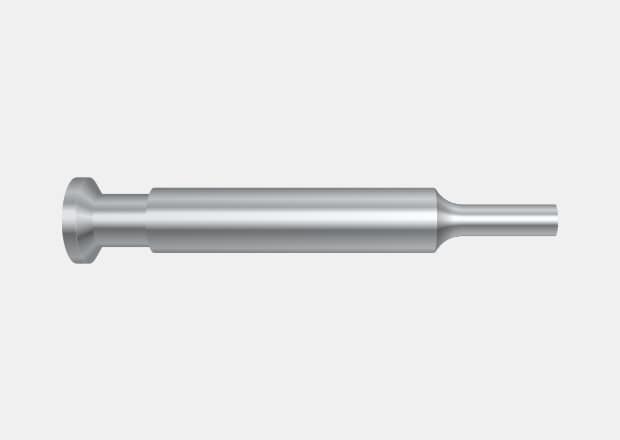

The following explains the part names of injection needles and typical types of needle tips.

Parts of an Injection Needle

-

1Blade surface (bevel)

-

2Outer diameter (gauge)

-

3Needle length

-

4Needle tip (blade edge)

-

5Shaft

-

6Needle hub (color classification by gauge number)

Needle Size (G)

| G | Outer diameter (mm inch) | Hub color (Color code) | Purpose | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

|

G:18

|

Outer diameter (mm inch)

ø1.2 ø0.0472"

|

Hub color (Color code)

Pink

|

Purpose

Blood transfusion

|

||||||||

|

G:19

|

Outer diameter (mm inch)

ø1.1 ø0.0433"

|

Hub color (Color code)

Cream

|

Purpose

Blood transfusion

|

||||||||

|

G:20

|

Outer diameter (mm inch)

ø0.9 ø0.0345"

|

Hub color (Color code)

Yellow

|

Purpose

Intravenous injection / venous blood collection

|

||||||||

|

G:21

|

Outer diameter (mm inch)

ø0.8 ø0.0315"

|

Hub color (Color code)

Dark green

|

Purpose

Intravenous injection / venous blood collection

|

||||||||

|

G:22

|

Outer diameter (mm inch)

ø0.7 ø0.0276"

|

Hub color (Color code)

Black

|

Purpose

Subcutaneous injection / intravenous injection / intramuscular injection / venous blood collection

|

||||||||

|

G:23

|

Outer diameter (mm inch)

ø0.6 ø0.0236"

|

Hub color (Color code)

Dark blue

|

Purpose

Subcutaneous injection / intravenous injection / intramuscular injection / venous blood collection for children / arterial blood collection

|

||||||||

|

G:24

|

Outer diameter (mm inch)

ø0.55 ø0.0217"

|

Hub color (Color code)

Medium purple

|

Purpose

Subcutaneous injection

|

||||||||

|

G:25

|

Outer diameter (mm inch)

ø0.5 ø0.0197"

|

Hub color (Color code)

Orange

|

Purpose

Subcutaneous injection

|

||||||||

|

G:26

|

Outer diameter (mm inch)

ø0.45 ø0.0177"

|

Hub color (Color code)

Brown

|

Purpose

Intracutaneous injection

|

||||||||

|

G:27

|

Outer diameter (mm inch)

ø0.4 ø0.0157"

|

Hub color (Color code)

Medium gray

|

Purpose

Intracutaneous injection

|

||||||||

* The ISO standard defines the color coding of needle hubs.

Typical Types of Needle Tips

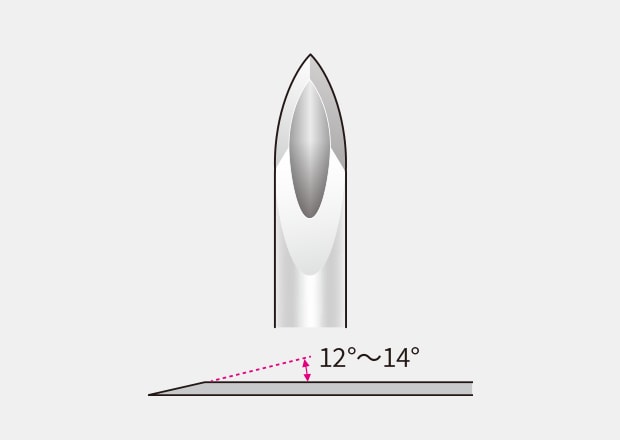

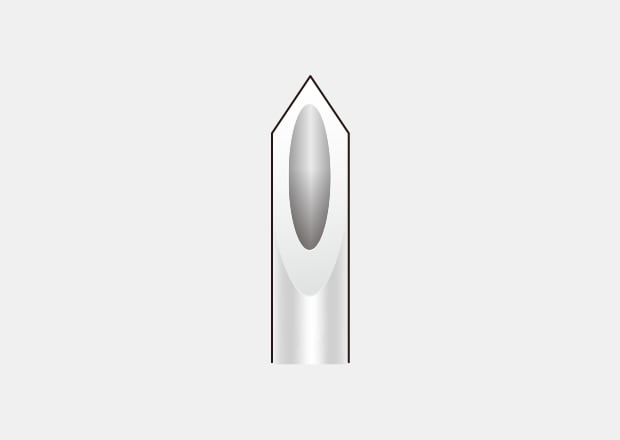

Lancet point (regular bevel)

The sub edge surfaces are created on the right and left of the main surface of the needle tip to minimize resistance to the needle. This is the typical shape of needles (including injection needles). The lancet point for subcutaneous injection is called a regular bevel, with blade surface angles ranging from 12° to 14°.

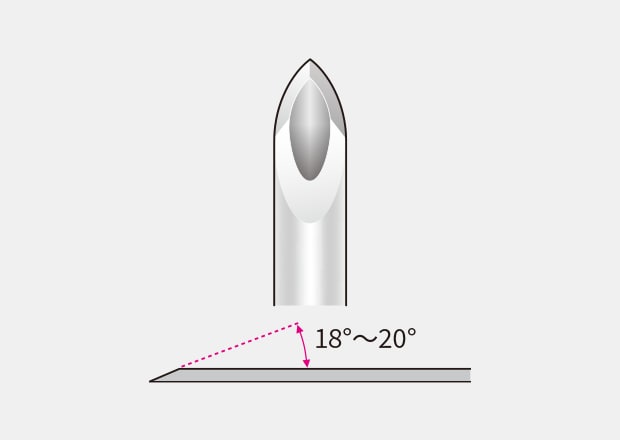

Lancet point (short bevel)

This type has a shorter blade edge than regular bevel needles to reduce side effects, including tissue damage. The edge surface angle is sharp, ranging from 18° to 20°, which increases the resistance to the needle and reduces the cutting quality. This is used for blood collection where blood vessels may be damaged.

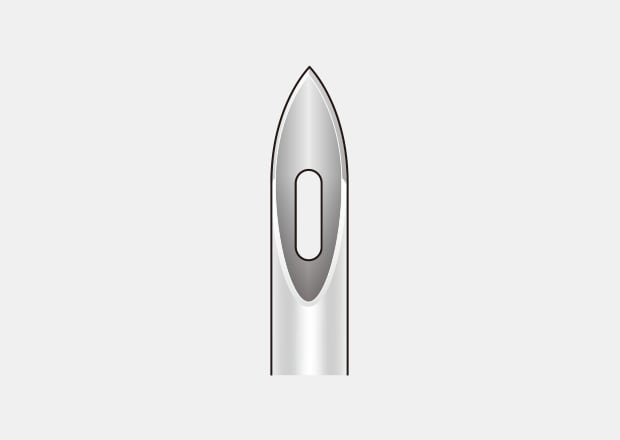

Back cut point

A small edge surface is created on the back side of the main edge surface. There is a mount-shaped protrusion when you view the needle tip from the main edge surface. The cutting quality is high and it effectively mitigates pain.

Lancet point (back-eye)

The needle tip has a hole drilled in the back of the lancet point. This special hole was developed for use in dialysis. The hole on the back reduces the internal pressure on the blood vessel wall, and prevents narrowing of the blood vessel and damage to red blood cells.

Huber point

This needle tip is curved toward the bevel face, and used to inject medicine through a port implanted under the skin. The port is like a tank to store medicine. Unlike drip infusion, patients do not have to remain still during infusion, so they can work or take part in sports without any special considerations, even when the port is not in use.

Medical Industry Applications — Injection Needles and Scalpels

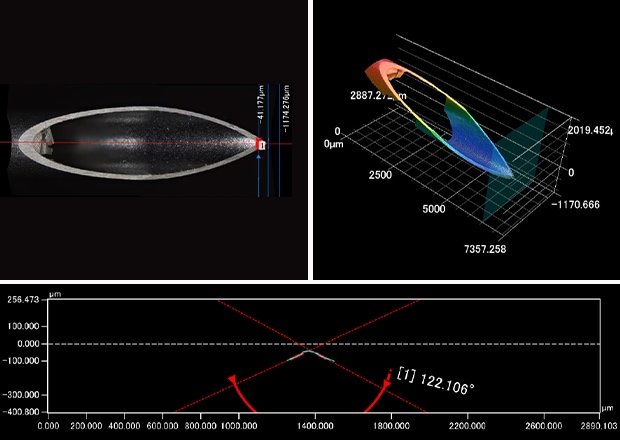

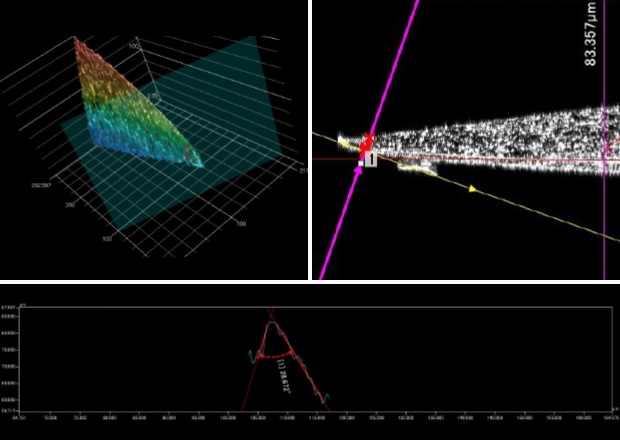

Needle Tip Angle Inspection

Blade Edge Angle Inspection (For Ophthalmic Scalpel)

Get detailed information on our products by downloading our catalog.

View Catalog

Implant

Implant is a generic name for devices and materials that are placed in a human body. Implants include cardiac pacemakers, artificial joints, and artificial dental roots.

Artificial dental roots are called dental implants.

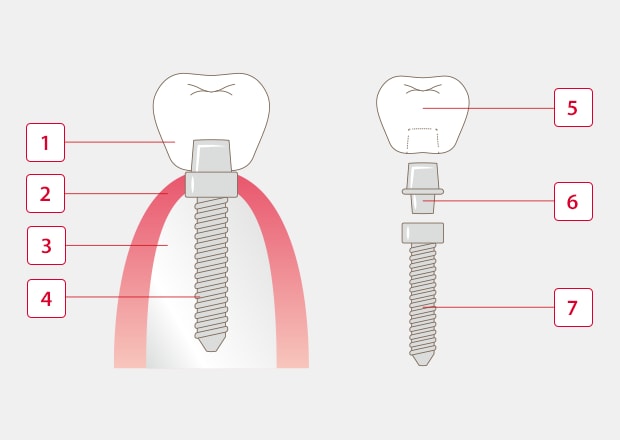

Names of Dental Implant Parts

-

1Artificial tooth

-

2Gum

-

3Jawbone

-

4Implant

-

5Crown (artificial tooth)

-

6Abutment (joint)

-

7Implant (artificial dental root)

Crown (artificial tooth)

These are artificial teeth that are fixed to abutments by cement or screws.

Abutment (joint)

They are placed between implants and artificial teeth. In general, they are fixed to implants by screws.

Implant (artificial dental root)

They are placed in the bone.

Materials and Features of Dental Implants

Crown (artificial tooth)

- Zirconia ceramics:

- Zirconia ceramics have the largest benefits, including a pleasing appearance and strength. Ceramics are fused to zirconia (white non-metal material and artificial diamond).

- All ceramics:

- All parts are made from ceramics. They have beautiful transparency and gloss and there is no degradation or discoloration over time. They are weaker than Zirconia ceramics or metal bond, so sometimes they break or chip.

- Metal bond:

- These implants are made by fusing ceramics to metals. There is no degradation or discoloration over time, but as it includes a metal frame, the appearance isn’t as good. Also, there may be concerns regarding metal allergies depending on the metal used.

- Full-zirconia ceramics:

- They are entirely made from zirconia that has excellent durability. They do not discolor or stain, but they have inferior transparency and color finishing quality as compared to ceramics.

Abutment (joint)

- Titanium, Zirconia:

- Joint parts between artificial teeth and implants. Titanium has excellent strength, resistance to corrosion, and durability, but the appearance isn’t as good. Zirconia offers strength and no risk of metal allergy. Also, as the color is close to that of natural teeth, the appearance is good.

Implant (artificial dental root)

- Titanium:

- They are placed in the jawbone. The material is titanium that is combined with bone.

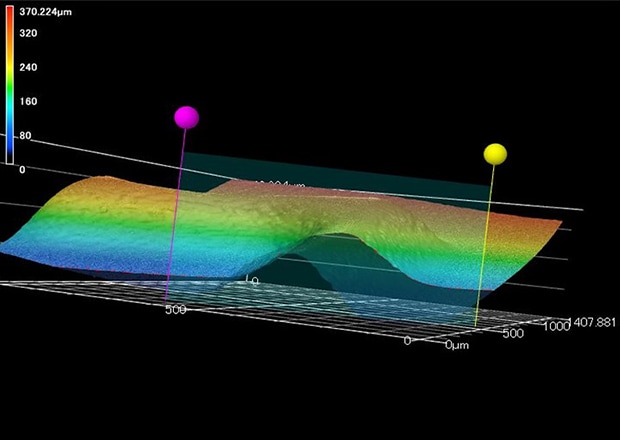

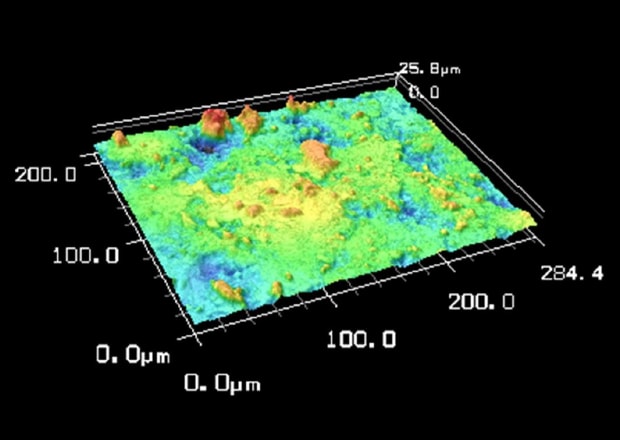

Medical Industry Applications — Implants

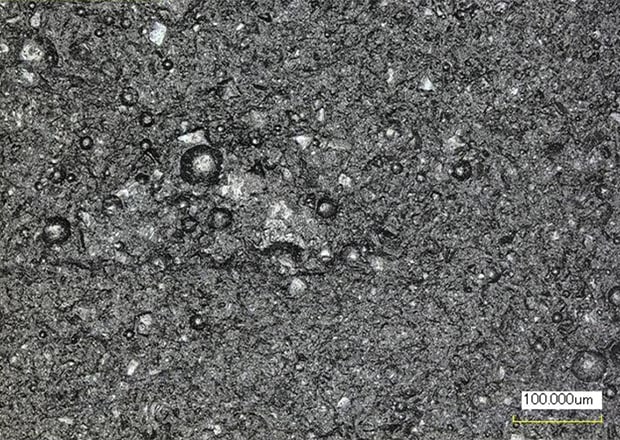

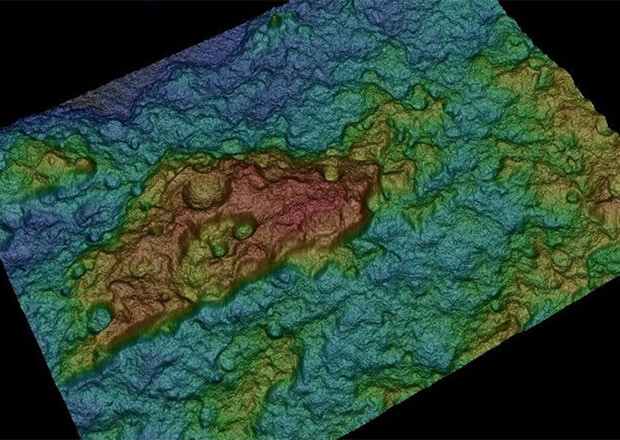

Implant Surface Shape Inspection (16-Bit Laser Image)

Implant Surface Shape Inspection (16-Bit Laser Image)

We’re here to provide you with more details.

Reach out today!

Tablets

Tablets are solid pharmaceutical products in which active ingredients are compressed and formed.

As tablets are portable, easy to understand the proper dose, and can be stored for long periods, they are the most commonly used form of medicine.

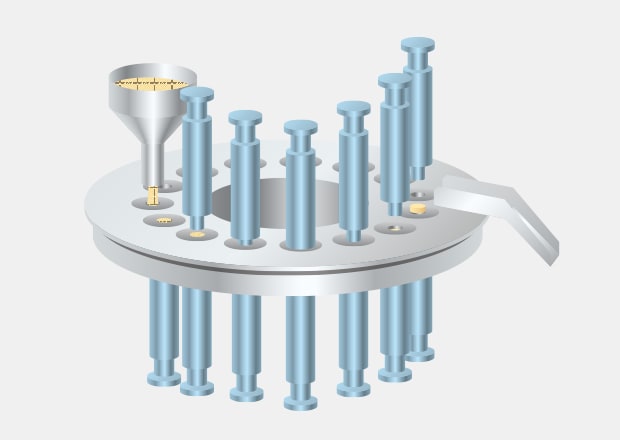

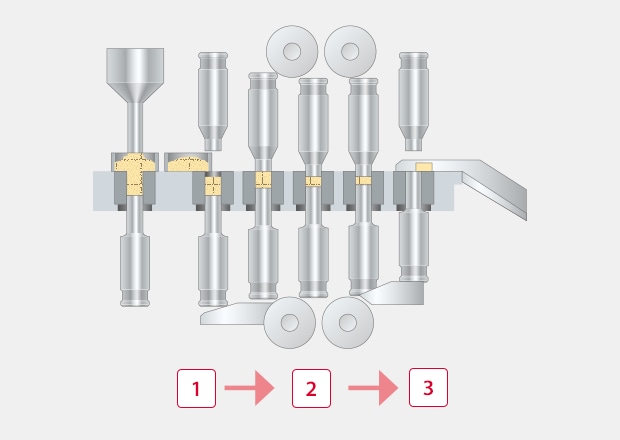

Tablet press

Tablet Press

Rotary molding machines are generally called tablet presses. Powder is automatically measured and put into a die, and then a punch presses it to form a tablet. Filling, compressing, and discharging are performed continuously.

-

1Filling

-

2Compressing

-

3Discharging

Punch

Die

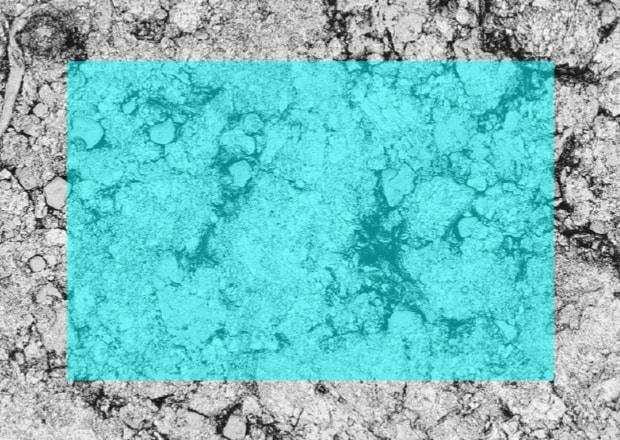

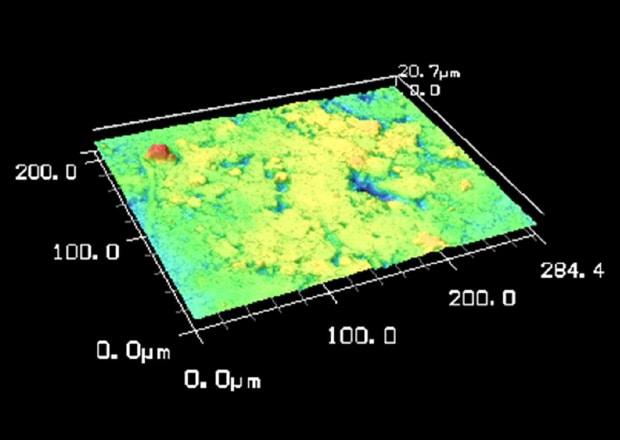

Medical Industry Applications — Tablets

Machine Punch Shape Inspection

Surface Roughness Inspection

| Ra | Ry | Rz | tp (50%) | RMS |

|---|---|---|---|---|

|

Ra

0.638 µm

|

Ry

13.361 µm

|

Rz

6.350 µm

|

Rz

98.55%

|

Rz

1.093 µm

|

| Ra | Ry | Rz | tp (50%) | RMS |

|---|---|---|---|---|

|

Ra

1.206 µm

|

Ry

14.463 µm

|

Rz

8.330 µm

|

Rz

65.98%

|

Rz

1.755 µm

|

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us