Quantifying Polished Surfaces

Polishing refers to the use of chemicals to make a surface smoother. Polishing is used in various industrial fields, such as lapping during the semiconductor manufacturing process. This section introduces the basic characteristics of polishing and etching, along with application examples of 3D profile measurement systems.

We’re here to provide you with more details.

Reach out today!

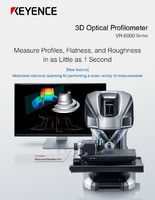

Lap Polishing

Place a target on a flat surface plate called a lapping machine, supply lapping powder (such as diamond, silicon carbide, or alumina) between the target and surface plate as an abrasive, and rotate the table to polish the surface of the target.

-

1Side view

-

2Slurry

-

3Slurry feeder

-

4Wafer

-

5Carrier film

-

6Polishing pad

-

7Rotating table for polishing

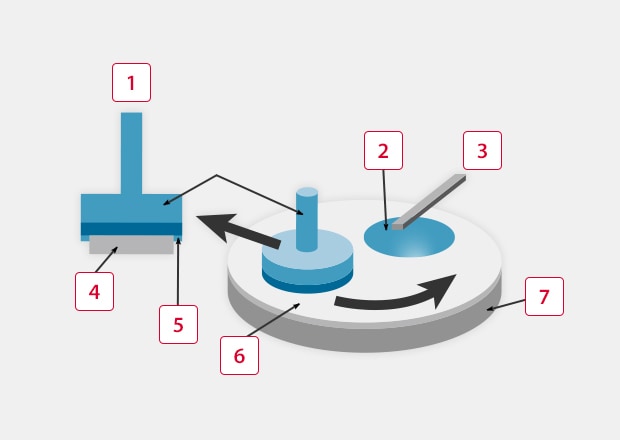

Buff Polishing

An abrasive compound is placed onto a wheel which presses against the surface to be polished. The wheel then spins to polish the surface.

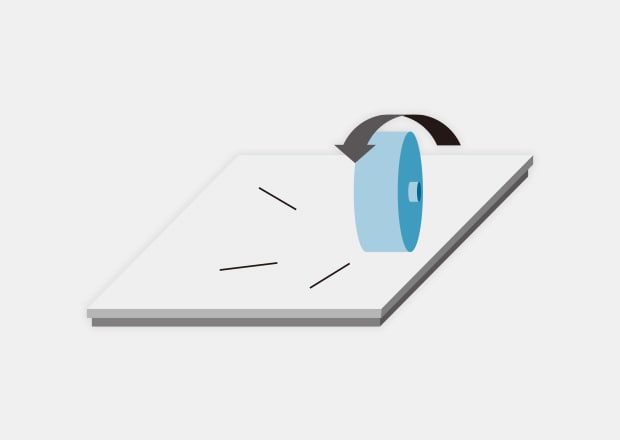

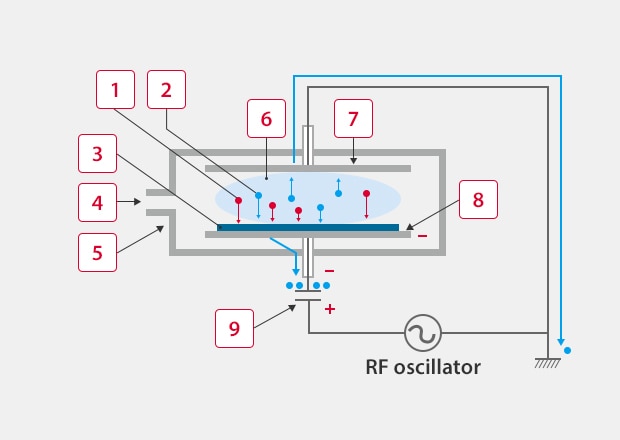

Electrolytic Polishing (Electropolishing)

The sample is immersed in a solution and an electric current is passed through it so that the sample acts as the anode. Small amounts of iron or nickel atoms dissolve from the opposite pole to etch the sample. The polishing surface can be changed by changing the location of the cathode. This allows for fine control of the roughness with a small amount of etching.

Sample Immersed in Polishing Electrolyte

-

1Power supply

-

2Electrolyte

-

3Opposite pole (Cathode)

-

4Sample (Anode)

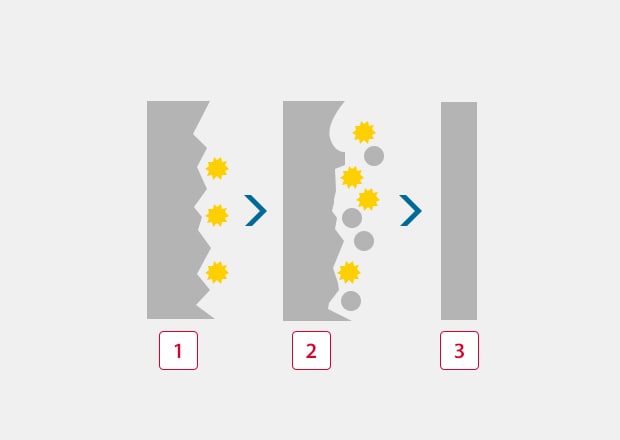

4: Changes in the Sample (Anode)

Electrolyzation preferentially dissolves projections to smooth the surface.

-

1Before polishing: Irregularities on the order of several micrometers

-

2During polishing: Surface irregularities being removed

-

3After polishing: Smoothed

Chemical Polishing

The sample is immersed in an acidic polishing solution to partially dissolve its surface. Unlike electropolishing, the polishing surface cannot be selected, so the entire surface in contact with the solution is etched uniformly.

| Electrolytic Polishing (Electropolishing) | Chemical Polishing | |

|---|---|---|

|

Polishing Amount

|

Electrolytic Polishing (Electropolishing)

Approx. 1 to 5 µm (Controllable with processing time and solution)

|

Chemical Polishing

Approx. 1 to 20 µm (Controllable with processing time)

|

|

Available Accuracy

|

Electrolytic Polishing (Electropolishing)

Sub-micron

|

Chemical Polishing

Micron

|

|

Electrode

|

Electrolytic Polishing (Electropolishing)

Required (Selective polishing based on the location of the electrode)

|

Chemical Polishing

Not required (Uniform polishing of entire target)

|

We’re here to provide you with more details.

Reach out today!

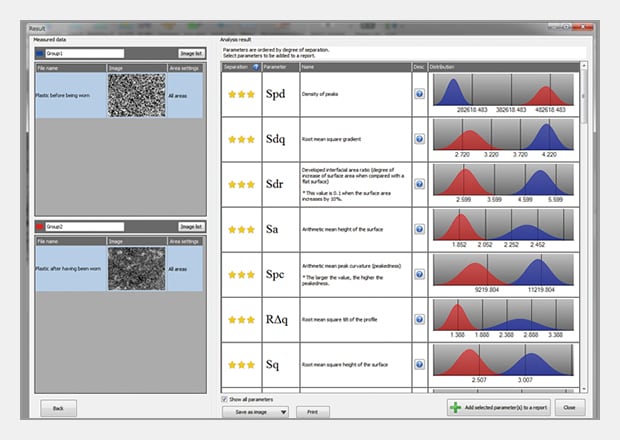

Wear Analysis Example

Analyzing surface texture and the pattern of wear before and after etching makes it possible to classify and quantify the material arrangement and chemical composition conditions in detail, reducing wasted manufacturing costs.

Conventional Method

Evaluation with a stylus-based profiler.

- Surfaces are subject to scratches caused by the measuring force of the stylus.

- The measurement must be repeated many times to account for surface fluctuations, increasing the amount of work required.

Laser Microscope

- Multiple data sets can be analyzed simultaneously, under the same conditions.

- Surface-based evaluation allows for analysis of roughness, volume, and surface area.

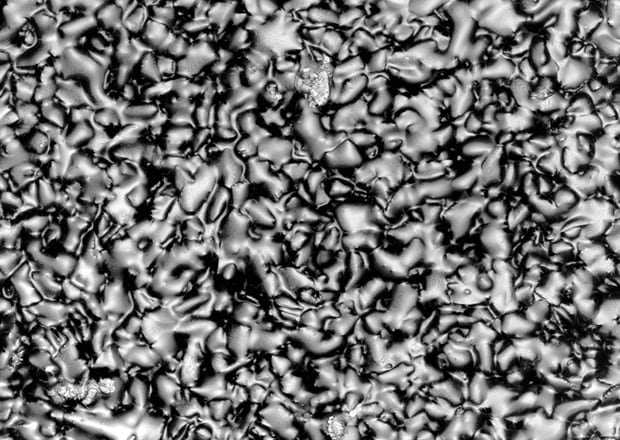

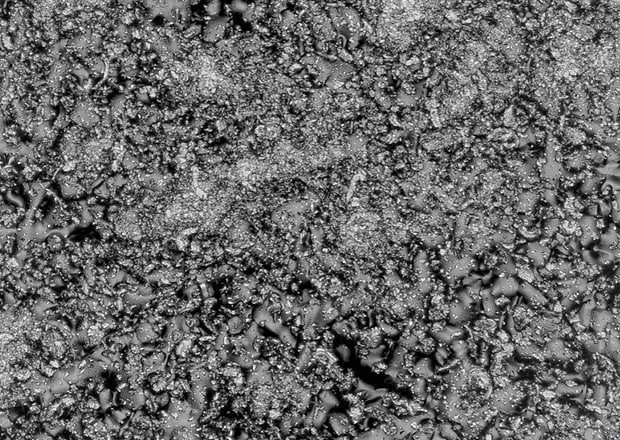

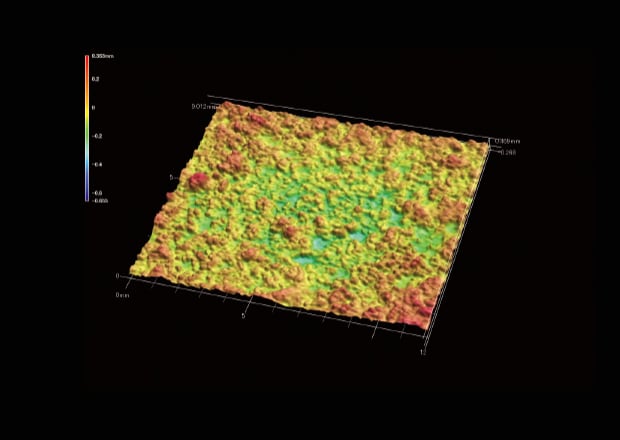

Surface conditions prior to wear

Surface conditions after wear

The projections on the surface have been worn off.

Analysis with a laser microscope

Using the parameter suggestion function automatically extracts the roughness parameters for which there were deviations in the values before and after wearing.

Get detailed information on our products by downloading our catalog.

View Catalog

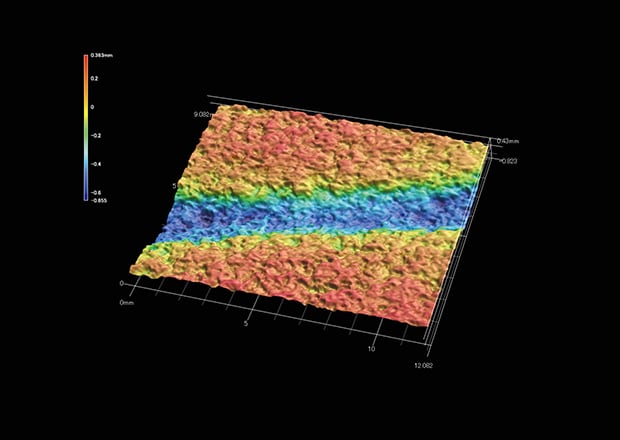

Polishing Pad Profile Measurement Example

The surface conditions of polishing pads affect the flatness and uniformity of the polished sample. Understanding the surface of polishing pads makes it possible to increase their quality and lifetime.

Conventional Method

Evaluation with an SEM.

- The measurement must be repeated many times, as the observable area is limited.

- Sample preparation is required, increasing analysis time.

Laser Microscope

- The measurement range is wide enough to evaluate the entire target with just one measurement.

- No sample prep required.

- The profile and irregularities of the surface can be quantified.

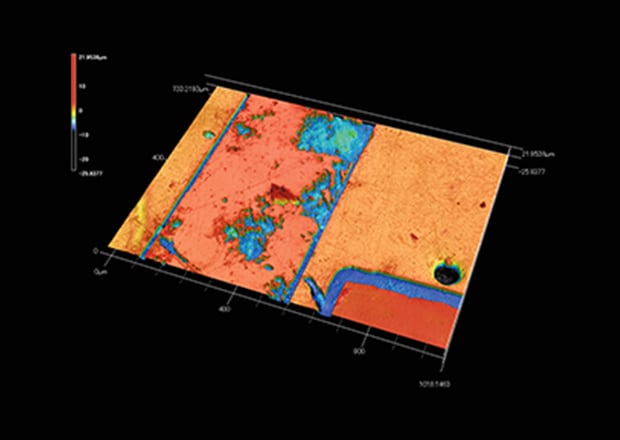

Surface profile of a polishing pad (good product)

Surface profile of a polishing pad (worn product)

The groove depth, width, and volume can be measured for worn pads. Changes recorded over time can be used to determine the pad replacement interval.

Get detailed information on our products by downloading our catalog.

View Catalog

Grindstone Profile Measurement Example

A grindstone contains abrasive grains of diamond plated on a base metal. Understanding the profile of electroplated grindstones can lead to improved yield.

Conventional Method

Evaluation with an SEM.

- The measurement must be repeated many times, as the observable area is limited.

- Analysis takes a long time.

- The sample size of SEMs is limited, so samples need to be cut for testing.

Laser Microscope

- There is no limitation on the sample size, which allows for non-destructive evaluation.

- The profile and irregularities of the surface can be quantified.

SEM image of a grindstone surface

Although the observation image is clear, it does not show the exact magnitude of irregularities.

3D image of a grindstone surface

Analysis with a laser microscope can quantify the surface profile and irregularities.

Get detailed information on our products by downloading our catalog.

View Catalog

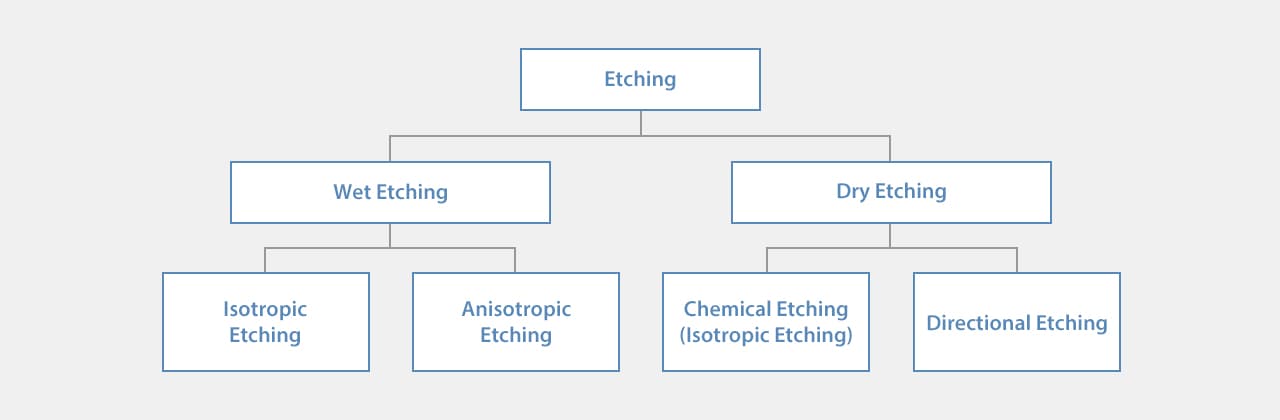

Various Types of Etching

Etching can be broadly divided into wet etching, which uses chemical solutions such as acids or alkali bases, and dry etching, which uses ions, gas, or radicals.

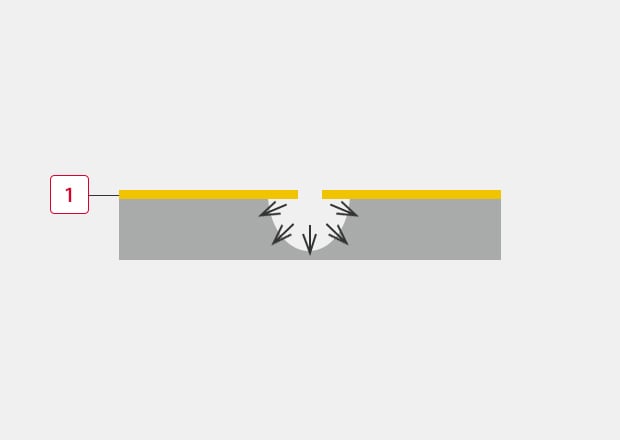

Wet Etching

Isotropic etching

At the mask opening, the target is etched radially at the same speed so that the area immediately below the mask is bored (side etching, undercut).

-

1Mask

Anisotropic etching

This method controls side etching to etch only in a specific direction by taking advantage of crystalline anisotropy.

-

1Mask

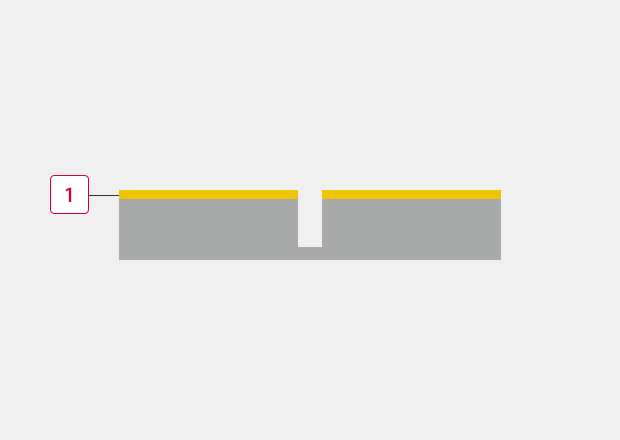

Dry Etching

Chemical etching (isotropic etching)

This method uses the chemical reaction between an ionized or radical reaction gas and the target.

-

1Ion plasma

-

2Resist

-

3SiO2 or other oxide film (insulating material)

-

4Silicon wafer

-

5Films not covered by the resist are removed by the ions

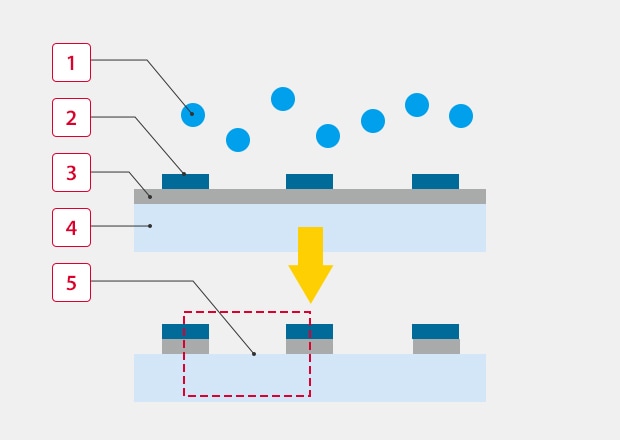

Directional etching

This method etches the target by emitting ions or high-speed neutral particles with directional characteristics against it.

-

1Positive ion (active gas)

-

2Electron

-

3Wafer

-

4Etching gas

-

5Etching chamber

-

6Plasma

-

7Opposite electrode (anode)

-

8Flat electrode (cathode)

-

9Blocking capasitor

We’re here to provide you with more details.

Reach out today!

Observing Polished Metal Structures

Metal structures that could only be seen with an SEM can be observed. Measurement of the height of parts eroded by etching allows for evaluation of the structure.

Conventional Method

Evaluation with an SEM.

- Only visual observation of metal structure is possible with a metallurgical microscope or an SEM.

- Visual observation requires the evaluation of a number of different areas. The result fluctuates greatly depending on the measurement point and operator, resulting in long analysis times.

Laser Microscope

- The high image quality allows observation of metal structures that could previously only be seen with an SEM.

- Since the profile and roughness of the surface is quantified, no labor is needed for analysis.

- Measuring the height of the parts removed by etching allows for identification of the components of the structure.

Observation image

3D image

Get detailed information on our products by downloading our catalog.

View Catalog

Etching Amount Evaluation Example

The effect of etching can be quantified by evaluating the surface profile or surface roughness at different intervals or temperatures.

Conventional Method

Evaluation with a metallurgical microscope or a stylus-based profiler.

- The reproducibility of magnified observation is poor and the reliability is low.

- Grooves that are smaller than the radius of the stylus tip cannot be measured.

Laser Microscope

- Differences in the surface profile can be quantified.

- Surface roughness can be evaluated without being influenced by stylus tip shape or wear.

Observation image

3D image

Etching time

0 minute

5 minutes

10 minutes

Get detailed information on our products by downloading our catalog.

View Catalog

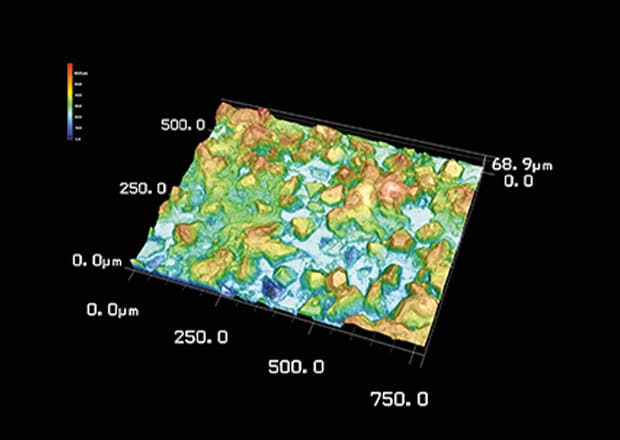

Example of Surface Roughness Measurement after Chemical Polishing

Measuring the surface roughness improves understanding of the effects of chemical polishing on the base material, which improves the yield rate.

Conventional Method

Evaluation with an SEM.

- Visual observation of the surface with a 2D image.

- Surface roughness measured with a stylus profiler fluctuates based on the measurement point, so multiple measurements must be made to collect representative surface roughness data.

Laser Microscope

- 2D and 3D images are captured, allowing for quantitative and qualitative understanding of the surface.

- Measuring roughness across the entire surface ensures a high degree of reproducibility.

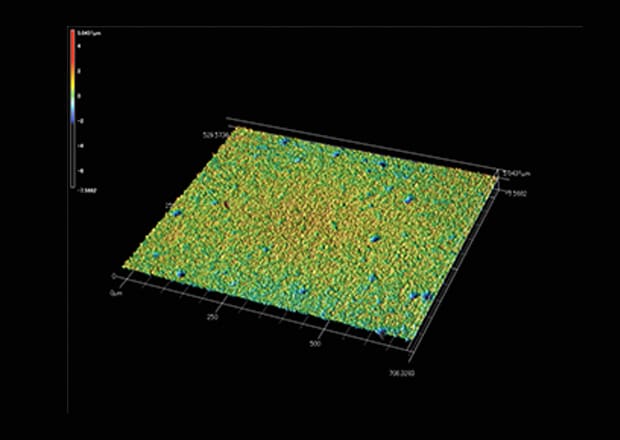

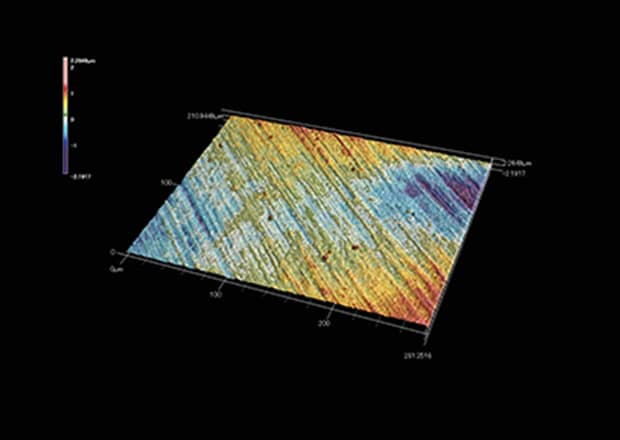

Before polishing

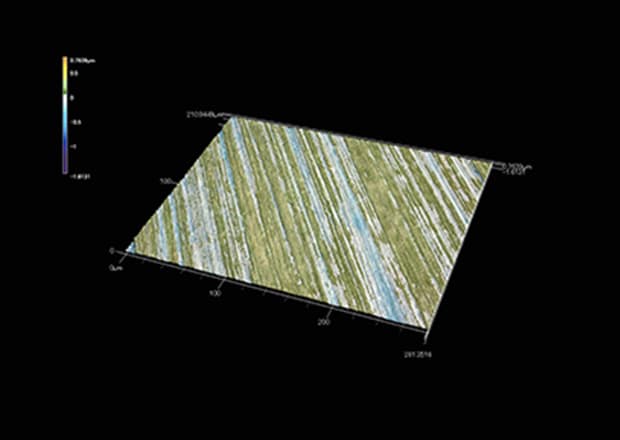

After polishing

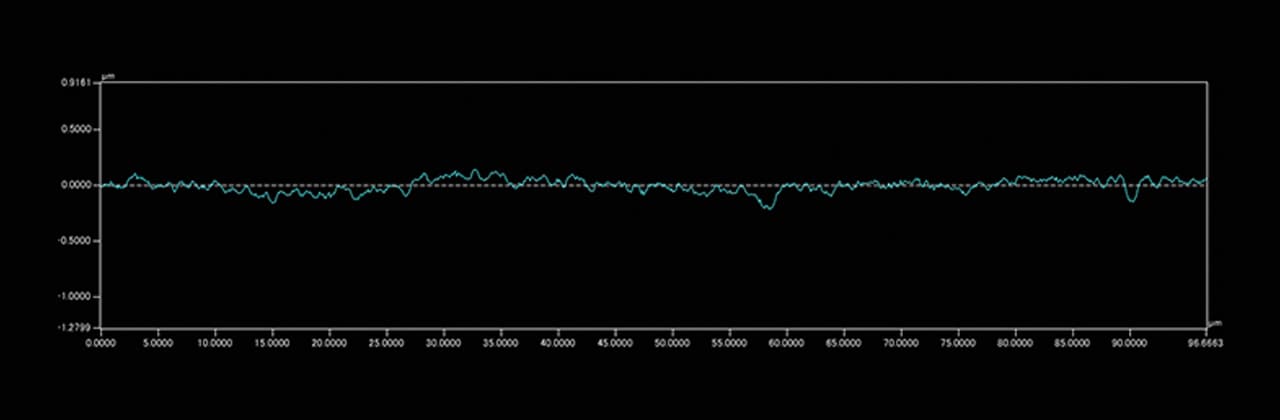

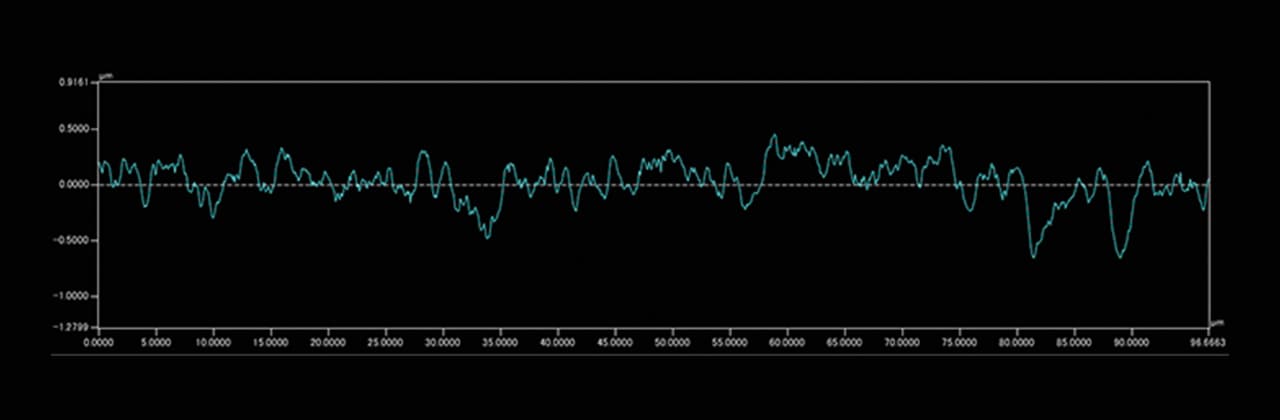

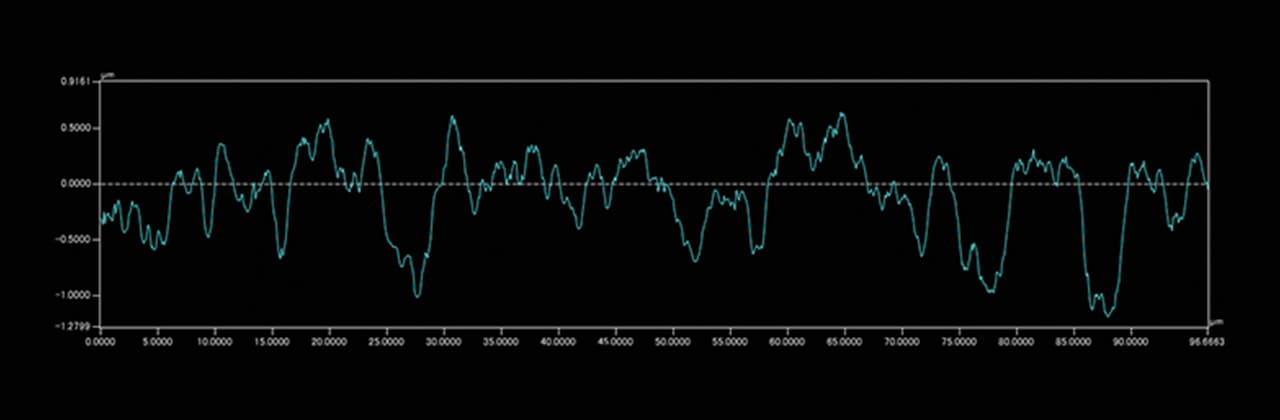

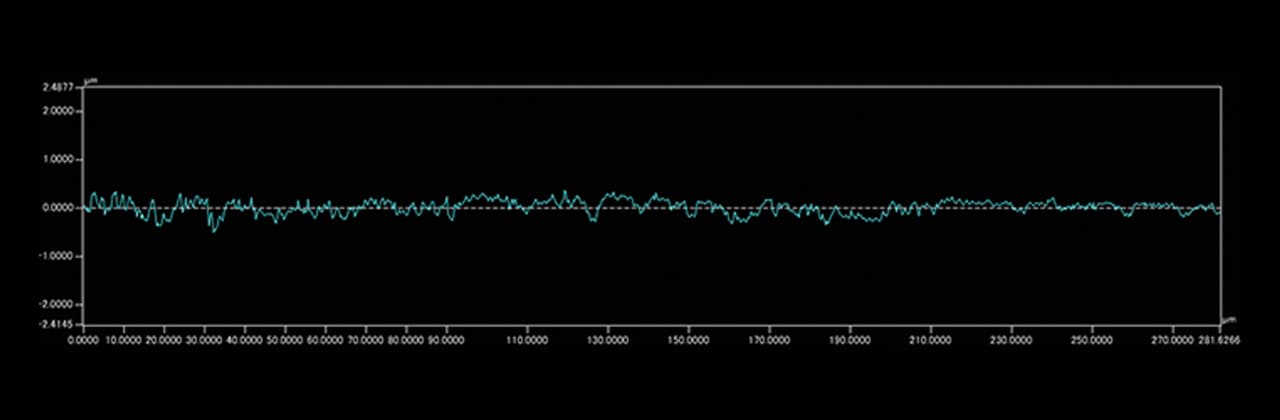

Surface profile before polishing

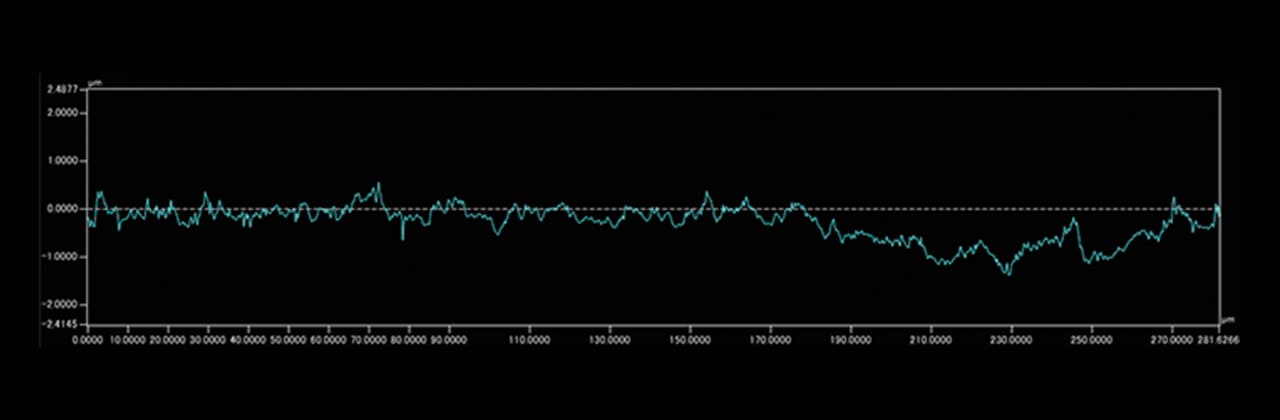

Surface profile after polishing

Get detailed information on our products by downloading our catalog.

View Catalog