Automotive Industry

Defective Electrostatic Coating Due to Dust Adhesion

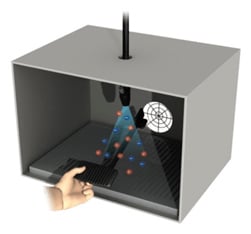

Dust adheres to brake pedals, air-conditioner components and other parts before the electrostatic coating process. If the parts are coated with dust on their surfaces, paint may accumulate in spots to cause uneven coating or peeling of the coating on the dust.

Conventional countermeasures

Air blow

- Cannot eliminate static electricity, increases the charge instead.

- Cannot remove foreign particles completely.

Countermeasures with static eliminators (ionizers)

Ionized air blows off foreign particles. Defective coating due to foreign particles can be reduced, which helps address complaints.

Improvements and Effects

Words from the worksite

Reduced defect rate

Defect rate before countermeasures: 3%, defect rate after countermeasures: 1.5%

In addition, the cost for the labor of workers cleaning off the adhered dust is reduced.