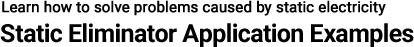

ESD Damage During IC Chip Pickup

After dicing, IC chips are picked up with a picking machine. The charging potential increases greatly during the pickup due to the electrostatic charge generated when the IC chips are removed from the dicing tape. This leads to electrostatic discharge (ESD) in the surrounding jigs and other chips, resulting in damage.

Dicing: the process in which IC chips are cut out from a wafer.

Pickup: lifting chips with a vacuum pickup tool after dicing.

Conventional countermeasures

Conventional static eliminator

- The capability is insufficient to eliminate sudden and high electrostatic charge during pickup. The effect decreases significantly in a short period.

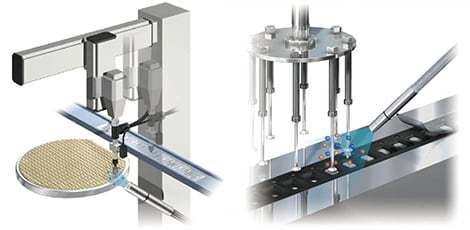

Countermeasures with static eliminators (ionizers)

An ionizer can reliably prevent the production of defective products and reduce disposal cost.

Improvements and Effects

Words from the worksite

Reduced disposal cost of defective products

Disposal cost due to ESD damage: $1,000/month x 12 months = $12,000/year

In addition, the labor for the maintenance of static eliminators can also be reduced.