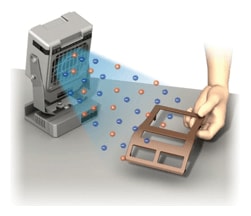

Dust Adhering to Resin Panels

Parts made of resin are easily charged with static electricity so dust and other foreign particles often adhere to them. Since panels are exterior parts, there is a strict delivery standard for dust adhesion. Dust must be removed completely before pre-shipment inspection.

Even if the dust is removed with an air blow, it may adhere to the panels again due to the an electrostatic charge.

Conventional countermeasures

Air blow

- Cannot eliminate static electricity, increases the charge instead.

- Cannot remove foreign particles completely.

Countermeasures with static eliminators (ionizers)

Ionized air prevents defective products caused by foreign particles. This measure is taken at the same time as pre-shipment inspection (such as burr inspection). The problem can be solved reliably without increasing takt time.

Improvements and Effects

Words from the worksite

Reduced cost for preventing the release of defective products

Disposal cost of $10,000/year + Recall cost (transportation and on-site service travel costs) of $5,000/year = $15,000/year

In addition, the increased level of trust and the solution can be good PR for the company's support system.