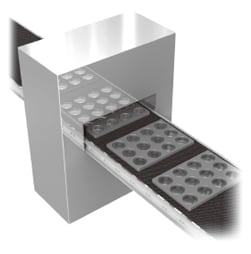

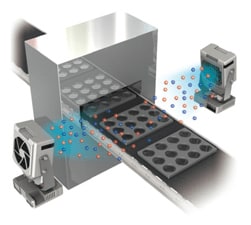

Dust Adhesion on Lenses Between Cleaning and Deposition

After lenses are cleaned, they are aligned in a case and transferred to the deposition process. During the transfer, airborne dust and other particles charged with static electricity may adhere to the lenses. Even if the dust is removed with an air blow, it adheres to the lenses again due to the force of the electrostatic charge.

Conventional countermeasures

Wiping

- Long work time.

- Fiber dust left on the lenses.

Countermeasures with static eliminators (ionizers)

An ionizer reduces the work time and eliminates foreign particles effectively.

Improvements and Effects

Words from the worksite

Reduced work time

Work time before the measure (20 lenses): 5 seconds

Work time after the measure (20 lenses): 2 seconds

Although calculating the total man-hours is difficult because the number of lines and product types vary, there is definitely an improvement.

In addition, there are other invisible effects such as improved trust level in terms of quality.