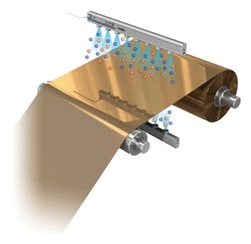

Dust Adhesion on Copper Foil Surface

In recent years, copper foils have been required to have higher quality in applications such as lithium ion batteries and printed wiring boards for mobile phones. There is a need to improve the effect of cleaning. Before removing the cutting oil or swarf on the copper foil surface with a cleaner, eliminating static electricity from the foil improves the effect of cleaning.

Conventional countermeasures

Resin brush

- It cannot eliminate static electricity, and increases the charge instead, causing secondary adhesion.

- The surface may be scratched by contact.

Countermeasures with static eliminators (ionizers)

The combination of an ultrasonic cleaner and a static eliminator allows cleaning and static electricity elimination without contact, which improves the effect of cleaning.

Improvements and Effects

Words from the worksite

Reduced disposal cost due to foreign particles

$9,000/half year x 2 = $18,000/year

In addition, there will be more cases where foils are made thinner, so conventional contact type cleaners cannot be used. It was crucial to improve the matter.