Paper & Textile Industries

Dust Adhesion During Non-woven Fabric Cutting Process

Fabric is charged with static electricity in the transfer line. Static electricity is also generated by the friction between the fabric and blade during cutting, which makes fiber dust of the fabric float in the surrounding air.

The airborne fiber dust sometimes adheres to the fabric which is being transferred. Charged fiber dust adheres again even if it is removed with an air blow.

Conventional countermeasures

Conventional static eliminator

- The static elimination speed is insufficient.

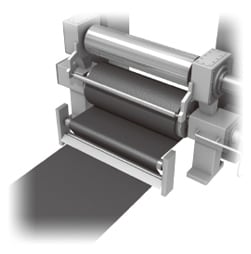

Countermeasures with static eliminators (ionizers)

An ionizer provides an effective measure against foreign particles, which leads to a decrease in complaints.

Improvements and Effects

Words from the worksite

Reduced cost for addressing defective products

Cost of recall and disposal of defective lots: $4,000/year

Recall cost (transportation and on-site service travel costs): $5,000/year

Cost of process improvement: $10,000/case