Automotive Industry

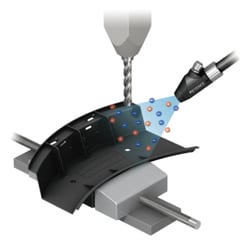

Cutting Swarf Adhering to Tools

In the process of cutting or polishing resin parts, swarf generated is charged with static electricity due to the friction with the tool. The swarf adheres to the tool, and if processing is continued, it may scratch or soil the worked surface or cause edge chipping.

Conventional countermeasures

Air blow

- Cannot eliminate static electricity, actually increases the charge.

- Cannot remove foreign particles completely.

Countermeasures with static eliminators (ionizers)

Ionized pulsed air blows off foreign particles.

It reduces disposal costs and saves takt time.

Improvements and Effects

Words from the worksite

Reduced disposal cost due to foreign particles and reduced work time

Disposal cost due to foreign particles: $500/month x 12 months = $6,000/year

Reduced work time: 60 seconds before countermeasures, 45 seconds after countermeasures

In addition, there are other invisible benefits of improved levels of trust.