Microscope

Microscope

Our microscopes are fully-automated systems that enable even novice users to capture high-resolution images.

| Global Headquarters | Osaka, Japan |

|---|---|

| Founded | May 1974 |

| Capital | 204,250,000 USD |

| 2024 Global Sales | 7,060,968,000 USD |

| Worldwide Employees | 12,261 |

| Note | US dollar amounts are converted from Japanese yen for convenience only at 150 JPY = 1 USD, the approximate exchange rate on March 19, 2025. |

Forbes “The World’s Most Innovative Companies” Top 100 for 8 consecutive years since its inception in 2011

BCG Value Creators Ranking Top 50 for 9 consecutive years 2014-2023

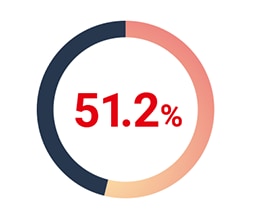

Operating profit of 51.9%

Operating profit of over 40% for 25 consecutive years

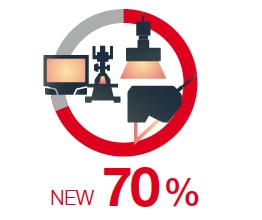

70% of our new products are World’s First or Industry’s First

Top 10 Companies in Japan based on market cap as of March 2025

Over US$ 90 Billion value total as of March 2025

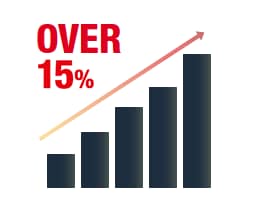

Over 15% average sales growth in 10 years in affiliate operation

250 offices in 46 countries

350,000 clients in 110 countries

90% coverage of 163 GICS* sub-industries in the world

*Global Industry Classification Standard

Equity ratio of 94.5%

Financially independent and debt free

Profitable for over 50 consecutive years

KEYENCE technology is sold to customers to improve their factory automation process used to produce products that you use every single day. Because we do business to business sales, we operate behind the scenes of all of these consumer products.

Think about your smart phone, the car you drive, the food you buy at the grocery store, and any other items you use on a daily basis. KEYENCE technology can be sold to the companies making these products in order to increase their production, become more effective, and enable them to create the next great product for their own business.

Automobile Industry

Medical & Pharmaceutical Industry

Smartphone Industry

Logistics Industry

Renewable Energy Industry

Food & Beverage Industry

Entertainment Industry

Agriculture Industry

Factory Automation is indispensable for manufacturing.

KEYENCE products play a key role in factory automation by increasing productivity, improving quality and decreasing cost.

These are tasks that manufacturing companies are working on now and for the future.

More

More

More

More

More

More

More

More

More

More

More

More

More

More

What will be made and where it will be made will change,

but manufacturing will survive as long as people need products.

Microscope

Microscope

Our microscopes are fully-automated systems that enable even novice users to capture high-resolution images.

3D printer

3D printer

Our high-resolution and user-friendly 3D printers can be used in manufacturing for rapid prototyping.

Automation Sensors

Automation Sensors

Our automation sensors can be used to detect the absence or presence of parts, as well as color and shape to ensure proper mounting of all parts.

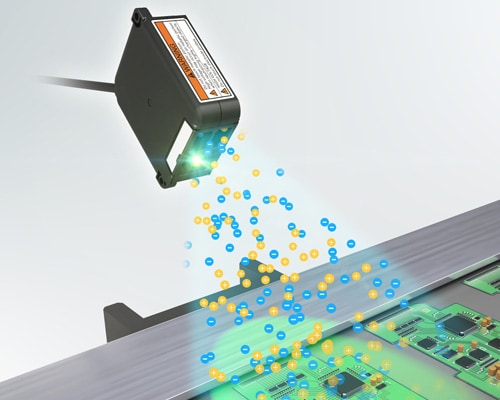

Static Eliminators

Static Eliminators

Our static eliminators are typically used in manufacturing environments to protect workers, machinery, and products.

Machine Safety

Machine Safety

Our WORLD'S FIRST safety scanner with a built in camera can be used to capture images or video when an object or person enters what would be consider a dangerous zone near operating machinary.

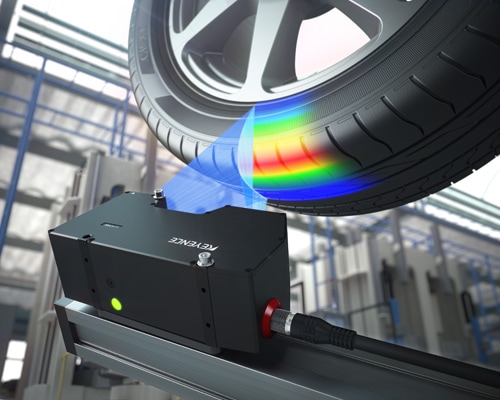

Measurement Sensors

Measurement Sensors

Our measurement sensors can be used to detect height, height differences, width, and other measurements to enable reliable quality and process control solutions for our customers.

Laser Markers

Laser Markers

Our laser markers use high-energy light to mark the surface of parts at a high speed (think logos, text, barcodes, etc.)

Barcode Readers

Barcode Readers

Our barcode readers can quickly extract 2D codes from a captured image and can decode it for uses such as traceability, product management, and other uses.

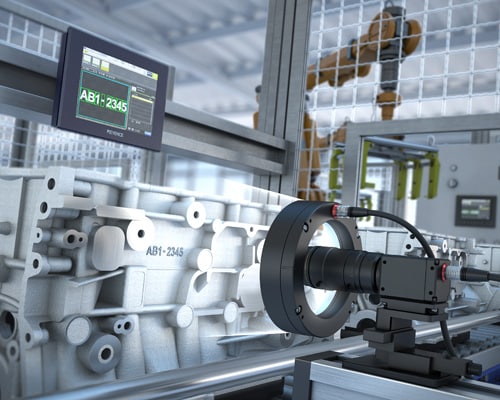

Vision Systems

Vision Systems

Our vision systems comprised of the industry's fastest cameras provide solutions to the most challenging inspections in manufacturing such as inline measurement and surface inspection.

Instant Measurement Systems

Instant Measurement Systems

Our measurement systems can perform up to 99 dimiensional measurements in 3 seconds or less at the push of a button to assist with offline precision of parts.

Mobile Computer

Mobile Computer

Our mobile computers are highly portable devices used for reading and collecting data such as barcodes, 2D codes, serial numbers, and expiration dates.

Mobile Computer

Mobile Computer

Our mobile computers are highly portable, single-handed devices used for reading and collecting data which can be used for store stock management in the retail industry.