XT Camera Processing Principle

9.44 megapixel CMOS image sensor for high-resolution images

Equipped with a 9.44 megapixel CMOS image sensor, best-inclass for inline 3D cameras. Capable of high-accuracy wide-field image capture in both 2D and 3D.

Telecentric lenses with no deviation due to positioning

The use of high-precision telecentric lenses reduces the impact of the imaging angle and allows for images to be captured without blind spots, allowing the user to see the actual dimensions of the workpiece.

Direction-independent 4-transmitter RGB projector

Captures images without blind spots and without any impact from imaging direction through use of 4-directional pattern projection.

Illuminates using individual RGB lighting, allowing for highresolution color images to be captured like those captured with a 3CCD camera.

Applications

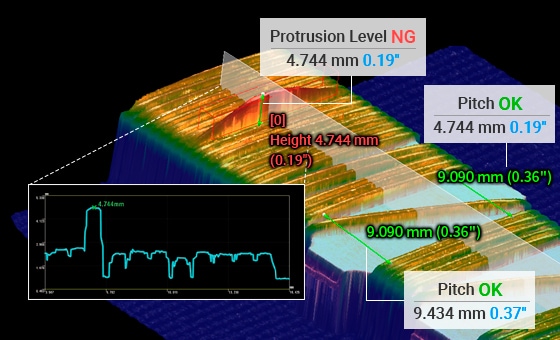

Coiled wire external appearance and dimension inspection

Capable of acquiring a cross-sectional profile of any location on a 3D shape at any angle and any position and of measuring the actual dimensions.

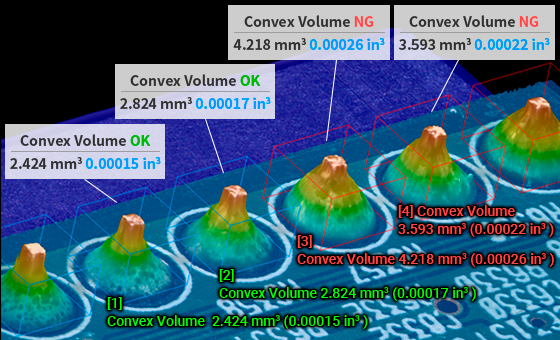

Solder appearance inspection

Uses actual dimensions to measure the volume, cross-sectional area, maximum height and other features, allowing for inspections of solder irregularities, cold solder joints, bridges, peaks and other anomalies.