LumiTrax™ Specular Reflection Mode Processing Principles

Calculate using images with different stripe patterns

Create an image with the defect extracted

Multiple images generated using different calculation methods

Major image types that can be generated with a single capture

| Image type |  |

|

|

|

|

|---|---|---|---|---|---|

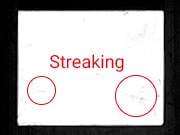

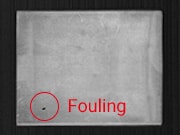

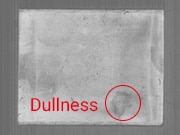

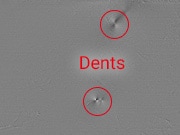

| (1) Normal image | (2) Specular reflection image | (3) Diffuse reflection image | (4) Gloss ratio image | (5) Shape image | |

| Image generation method | Averaging of all captured images | Extract only the specular reflection component from stripe patterns | Compare (1) and (2), extract the diffuse reflection component | Compare (2) and (3), extract the differences in gloss/shininess | Extract uneven fluctuating portions from the undulations in the stripe pattern |

| Main applications | Understand overall image, used for position correction reference | Used for inspection of streaking and abrasion on glossy surfaces | Used for inspection of debris or fouling | Used for damage inspections for cylinders and sides, surface dullness, etc. | Used for inspection for dents and shallow unevenness |

Applications

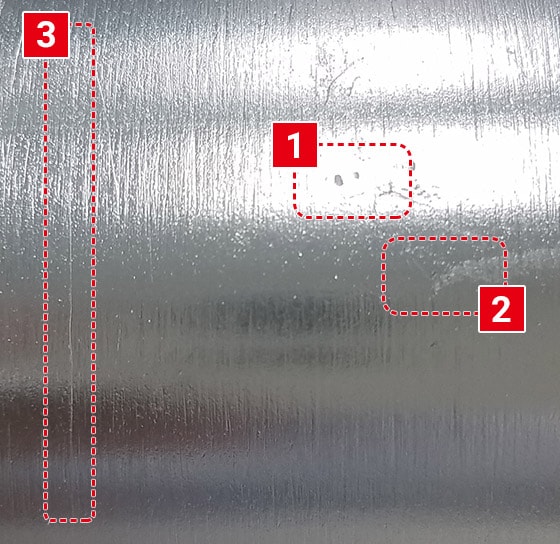

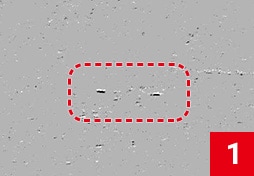

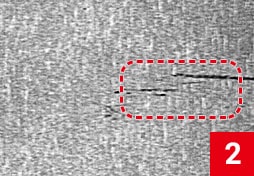

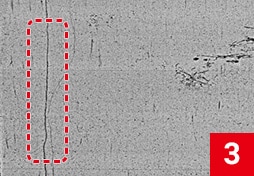

Inspection of metal cylinder surfaces (bearings, etc.)