Establishing Association and Operation Framework

Understanding the Association Order to Achieve Traceability

Building an Identification System explained identification to precisely recognize raw materials, parts, and products. This section describes association, for linking identified objects and information.

Association with a Process One Step Upstream or Downstream

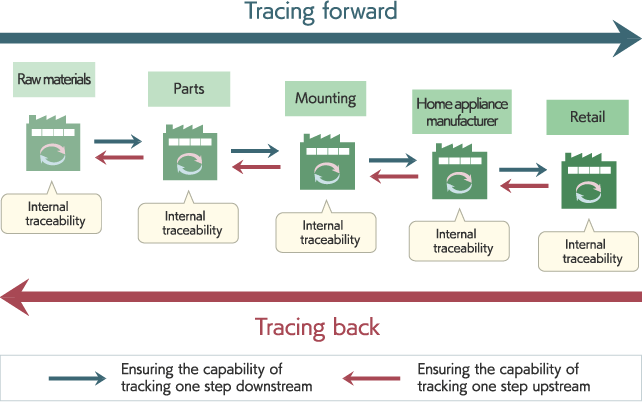

Association is a rule that links an object to an object, an object to information, or information to information, to enable tracing forward/back based on the identification number. On this basis, this section digs down into association in more detail by using an example of actual production processes.

First, ensure traceability to the suppliers of the parts (operators one step upstream) and the ship-to parties (operators one step downstream). Check "when, from whom, and how much you received of what parts" on the delivery slips from suppliers, assign identification numbers linked to that information to the part, and record/store the information within the company or plant. This ensures the capability of upstream tracking. When a part is defective, you can point out the supplier by tracing back the record.

Next, ensure the capability to track to the ship-to parties (operators one step downstream) to which the products will be delivered. In addition to the supplier information, record and link the date and time of delivery from your company and product information to the identification number of the product to be delivered. This enables tracking of "when, to whom, and how much you shipped of what product."

To achieve traceability, it is important to clarify the flow outside of your company. Take a company manufacturing PCBs, for example. Assume that the company purchased solder from several companies. If some of the purchased solder is defective, the company can easily identify the relevant supplier as long as the capability of one-step upstream tracking has been ensured. Moreover, if the capability of one-step downstream tracking is ensured, the company can recall the PCBs manufactured with that solder by precisely pointing out the destinations, so that the loss can be minimized.

For representation formats, transfer media and recording media essential for implementing tracing forward/back, refer to Information to be Transferred and its Format.

Adding the Information of the Internal Traceability

Next, you need to understand the movements of raw materials, parts, and products within the company or plant. In the example of the electronic device industry mentioned above, you can ensure internal traceability by adding and recording information before and after each work task, such as the manufacturers of the solder, transistors, resistors, connectors and other components being used and the components being assembled. Internal traceability is explained in detail in What is Traceability?

The basic goal of association is to link processes one by one while maintaining the internal traceability as well as the capability to trace back/forward to the operators one step upstream/downstream. You can establish chain traceability in a natural form if you can establish association throughout all processes, such as the companies producing solder and resistors, the companies mounting these onto the PCBs, and the home appliance manufacturers installing the PCBs into their products.

Developing a Procedure Manual for Operations

When you complete identification and association, the information is linked to the objects in the flow and you are ready to trace forward/back. You have not yet achieved traceability until the rules for the identification and association are unified in the company and the information is collected and recorded accurately. You need to develop a procedure manual describing the information recording method and items, storage method and period, and so on. Training staff members is also necessary, including in-company training.

It is also important to establish systems to perform monitoring and internal/external audits to enhance the reliability of the traceability.

Monitoring

This is the activity of confirming whether the traceability system is operating in accordance with the procedures. You may want to make a monitoring plan in advance about when and who checks what and how. For example, the reliability of traceability improves if you make a plan for a daily check such as "the person in charge of the line shall check the information about the serial numbers flowing on the line every three hours."

Internal audit

Internal audits are an activity regularly carried out by the person in the company assigned to evaluate if traceability has been ensured and if the implementation and operation are effective. Monitoring is performed daily, whereas internal audits are conducted at certain intervals, such as once a month or twice a year. The audit checks that the operation, including monitoring, is performed in accordance with the procedures, whether tracing forward/back is actually possible, if any abnormalities are found in the quantity before and after work, and so on.

External audit

Internal audits are conducted by someone in the company, whereas external audits are outsourced to a third party organization for confirmation and evaluation of the performance. External audits are effective for maintaining high level reliability of traceability and gaining the trust of customers and consumers. The downside is that they are costly.

In reality, you need to select an optimum representation format, a transfer medium and a recording medium in accordance with the parts and products, consider the information to be acquired in each process, and implement equipment to achieve these, which depends on the parts and products being handled, production methods, scale, and so on.