Basic Rules for All Industries

Traceability Laws and Regulations Vital for Every Industry

This page introduces basic rules, laws and regulations related to traceability and quality management that apply to every industry, such as automotive, electronic device, food, and pharmaceutical. Standards and laws such as ISO 9000/9001 and the Measurement Act are familiar in the fields of quality management and production control. They play important roles in traceability as well.

Definition of the Term Traceability: ISO 9000

The International Organization for Standardization (ISO) has defined traceability as follows in ISO 9000:

- Meaning

- Traceability is the ability to trace the history, application, use and location of an item or its characteristics through recorded identification data.

There are two important requirements to meet this definition:

- You must clearly specify the identification unit (individual or by lot) of the object under consideration (raw material, part, or product).

- You must identify the object under consideration and record necessary information to allow tracing forward/back.

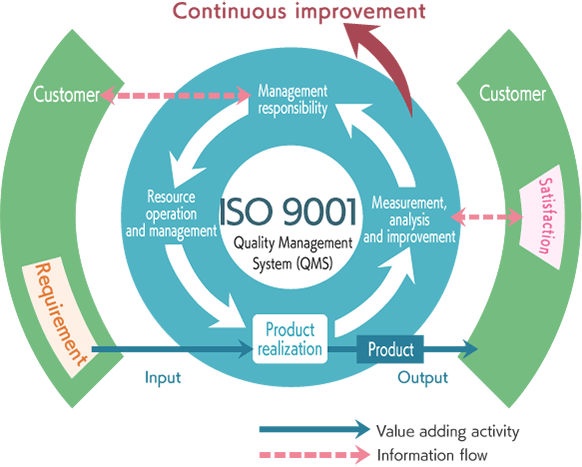

Definition of Traceability: ISO 9001

The quality management system of the International Organization for Standardization (ISO) is generally called the ISO 9000 series or ISO 9000 family and ISO 9001 is the most important standard in this family. A quality management system (QMS) is defined as "part of a management system intended to lead and manage an organization regarding quality."

ISO 9001 is an international standard based on the essence extracted from many successful cases regarding business improvement. Its purpose is to maximize profits by promoting business based on consistent rules concerning not only manufacturing processes or products, but also throughout the business from purchase to manufacturing, shipment, and service. We can say that it is the best guideline for improving routine work by eliminating problems such as inefficient procedures or repeated mistakes. By obtaining ISO 9001 certification, the company can also achieve social credibility and increase the trust of customers.

Two Concepts of Traceability

ISO 9001 specifies traceability in two sections: Measurement traceability and Identification and traceability. Since the topic of this page is traceability in the entire supply chain, this section describes identification and traceability.

Overview of Identification and Traceability

ISO 9001 states the following requirements regarding identification and traceability:

- Use suitable means to identify outputs when it is necessary to ensure the conformity of products and services.

- Identify the status of outputs with respect to monitoring and measuring requirements throughout production and service provision.

- Control the unique identification of the outputs when traceability is a requirement, and retain documented information to enable traceability.

These can be summarized as follows:

Identification is an especially important concept in these requirements. This identification means a common recognition shared among the entire production processes or the entire supply chain. Assume that you have a chip used for manufacturing a TV, for instance. The basics of identification are to ensure that this chip is recognized as the same one whether it exists by itself or is built in a product, and to allow everyone to know the current status of the chip, whether it has passed inspection or is under inspection, or in what process it is being worked on.

For that purpose, a traceability system identifies objects by using a representation format such as serial numbers or lot numbers, as well as the transfer medium such as labels and RF tags.

When all people related to the supply chain, including consumers, can recognize the status of the product and objects and information has been linked, tracing forward/back can be done easily. This ensures the quality and safety of the product.

Basic Safety Standard Concerning Electronic Control: IEC 61508

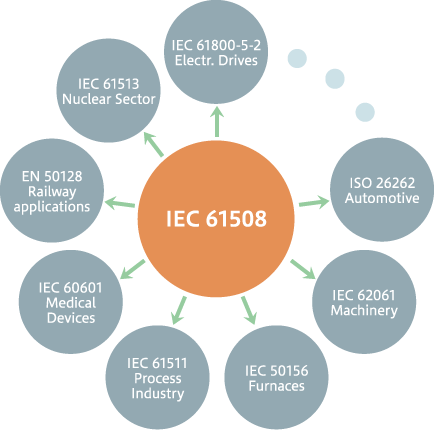

A lot of electronic control systems have been introduced to the manufacturing sites, such as industrial robot control using programmable logic controllers (PLCs) which is indispensable for factory automation (FA). IEC 61508 is a functional safety standard for such electronic and electrical systems. IEC 61508 was established by the International Electrotechnical Commission (IEC). It is a generic term for the functional safety standards concerning electrical, electronic and programmable electronic systems in all industries.

Its basic idea is to ensure safety and prevent accidents and disasters by adding functional equipment to protect human life, health, and environment (region) from hazardous events. IEC 61508 is the base of all functional safety standards. ISO 26262, which is the functional safety standard concerning automotive electrical/electronic systems, is also derived from IEC 61508.