Logistics Basics and Goals

When many people hear the word "logistics," they imagine a storage location such as a logistics center or warehouse, or they think about transportation and delivery using large trucks packed with cargo and container ships traveling between ports. However, these are a result of incomplete understanding that captures only a small portion of logistics. This section reintroduces the essence and goals of logistics, which is essential for modern life.

What is Logistics?

Logistics is the flow of goods. The essence of logistics is the flow that encompasses all of the steps and processes involved in delivering the goods of a company to consumers. Storage locations such as logistics centers and warehouses, delivery by large truck, and transportation by ship and airplane are just a simple checkpoint along this flow of goods. Information processing in distribution systems to deliver goods is ultimately included in this flow, and it will be explained in detail later. First understand that logistics is the flow for delivering goods.

Distribution and Logistics

The term distribution is easily mistaken for logistics. Logistics involves planning and carrying out the movement of the necessary materials and soldiers during war, for example. Logistics is an element that makes a difference between winning and losing in war. For that reason the necessary materials need to be supplied speedily and accurately, and the expertise to do that has been accumulated over a long period of time. Distribution is made up of product distribution, sales distribution, and procurement distribution when refined into smaller categories, and the concept of centrally managing this flow of complicated goods and making it more efficient is also called logistics. Logistics is the broad concept for distribution. However, equating distribution and logistics is not correct.

Goals of Logistics

There is a temporal and spacial gap between production and consumption. The goal of logistics is to fill in this gap. In the past, the main mission of logistics was to deal with the spatial distance by increasing transportation efficiency and reducing the time to deliver goods. However, now an important theme is not only speed but also how timely goods can be delivered to consumers. For this reason, a system is essential that can use functions such as transportation and storage as well as adjust the amount, time, and location of goods to prevent too much or too little inventory while delivering goods efficiently and without waste. The goal now is efficient logistics with no waste.

Logistics System

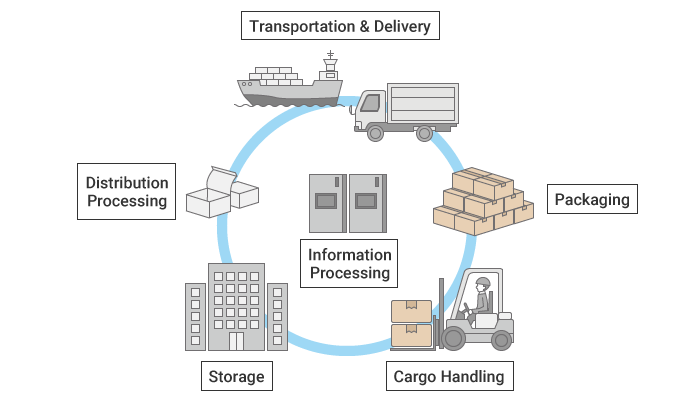

The system that delivers goods quickly and on time from the location of production to the consumer is the logistics flow shown below. Logistics also includes elements such as storing and packaging goods in addition to carrying and moving those goods.

- Transportation and Delivery

-

The functions that send goods from the producer to the consumer are transportation and delivery. Transportation, also called "primary transportation", serves to carry goods from point A to point B involving long distance movement. Delivery is also called "secondary transportation" and it serves to transport small lots of goods short distances. This function differs from transportation in that it is not a simple flow like movement from point A to point B. Instead, it sends goods from point C to multiple locations. Transportation and delivery are also said to make up about 60% of logistics costs.

- Storage

-

Logistics centers and delivery centers correspond to storage locations and serve to adjust the time difference between producers and consumers to deliver goods in a timely manner. Storage facilities with functions to maintain the quality and value of goods, such as cooler and freezer warehousing or food processing centers, also correspond to storage locations.

- Packaging

-

The process to protect products from physical damage (scratches and breakage) that occurs during the logistics processes.

- Cargo Handling

-

The work process to haul and move cargo in and out of logistics centers and warehouses is called cargo handling. Cargo handling is separated into six processes: assortment, loading/unloading, transportation, allocation (storage), sorting, and picking.

- Distribution Processing

-

Separating goods that enter a warehouse and distribution center, and then resorting and packaging them into units that are easy for consumers to purchase. Wrapping products, applying price tags, applying labels to imported goods, and checking clothing for needles are also types of distribution processing.

- Information Processing

-

Information systems that perform centralized management of the logistics flow from ordering to picking, shipping, and delivery are now essential to the world of logistics that handles thousands of items each day. This is because information systems are deeply involved in the traceability of goods that allows one to know where products that have been shipped from a production location or factory currently are and how long they will take to reach the assigned destination. IT devices such as handheld computers that link to the internet and intranet are used in these systems.