Receiving Inspection

Human error, such as omissions or forgetting to write things down, occurs frequently in conventional receiving inspections that use an inventory ledger. And this causes discrepancies in the recorded inventory and the actual inventory which leads to shipping mistakes. Even when handheld computers are used, cases stand out in which management of products without barcodes is difficult and the necessity to perform visual inspections leads to shipping mistakes. Visual inspections also take effort and use up human and time resources. This section gives receiving inspection methods and problems, and case studies using handheld computers that resolve these problems and make work more efficient.

Receiving Inspection Methods

Conventional Management Method Using Paper

Receiving at logistics worksites refers to receiving products that are delivered from suppliers or your own factory. During receiving work, the delivered goods are verified against the delivery statement sent with the goods to determine if there are mistakes in the product numbers and quantities, and the products themselves are inspected for damage and problems with quality. The receiving inspection is the process in which this receiving and inspection work is performed. For product management, the typical method is to write this down in a book called an inventory ledger.

Accurate Bookkeeping Is Important

Accurate bookkeeping of receiving and shipping goods is important in inventory management, and receiving inspections are important work in achieving accurate inventory management. If mistakes happen in the receiving inspection, discrepancies will occur between the recorded inventory and actual inventory, and when goods are moved, such as when they are allocated, picked, or taken out of inventory, the record will need to be verified again, work will stop and wasteful work will be necessary. For this reason, accurate bookkeeping is required in the receiving inspection.

Problems with Conventional Methods

Simple Mistakes in Manual Bookkeeping

Damage to goods and quality problems can be improved with methods such as opening the packaging and inspecting a portion or all of the goods, increasing the number of inspectors, and adopting various types of inspection equipment. However, when those results are recorded in the inventory ledger, mistakes occur such as skipping entries and omissions so long as that work is performed by humans. These simple mistakes due to manual work are explained in "Preventing Mistakes (Pokayoke)". These are fatal errors that occur because human cognitive functions are not suited to mechanical work and memorization. In other words, so long as receiving inspections and other work are performed manually, mistakes in the inventory ledger will continue to occur at a constant rate.

Problems with Barcode Management

Receiving inspections by barcode are given as a method to implement accurate inventory management. Scanning with a handheld computer is fast and accurate and it can identify small differences in numbers that are easy to miss due to the cognitive capacity of humans, so receiving and shipping management using barcodes and handheld computers can be thought of as the ideal method with few mistakes. However, sometimes goods to receive have no barcodes and only a product name written on the box. And often times, it is difficult to put a barcode on small parts and products due to the shape and materials. These kinds of products that lack barcodes are difficult to manage with handheld computers and require visual receiving inspections. This takes time and effort and also leads to mistakes.

Case Studies for Handheld Computers

This section introduces case studies using handheld computers that solve issues and problems in receiving inspections. Using handheld computers is effective for reducing receiving inspection mistakes and it leads to efficiency which also reduces time and costs.

Prevent Receiving Inspection Mistakes by Adopting Handheld Computers

There are limits to visual receiving inspections. However, adopting handheld computers can prevent these human errors. If handheld computers are adopted for inventory management overall in the logistics processes and not just in receiving inspections, information can be transmitted smoothly and waste can be eliminated for higher efficiency.

There are many types of handheld computers including those that can read various forms of information with OCR (optical character recognition), such as product numbers and quantities, in addition to reading barcodes and 2D codes. The read information can also be managed in a database and shared across the warehouse or delivery center to make later processes, such as picking and shipping work, more efficient.

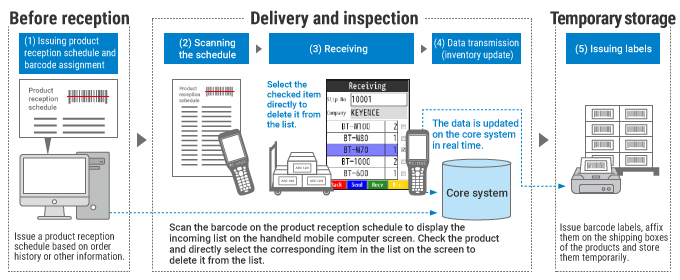

Products without Barcodes Can Also Be Managed

One of the issues with adopting handheld computers is products that lack barcodes during receiving. Normally, for products without barcodes, the product name, part number, and quantity must be checked visually and entered in the inventory ledger manually. With handheld computers, you can link to the system, perform a receiving check, update inventory, and issue a barcode label even for products without barcodes. This allows for reliable receiving inspections and inventory management for products without barcodes.

- Flow of Receiving Inspection Work Using Handheld Computers