Selecting a Displacement Sensor / Measuring System

When it comes to displacement sensors and measurement systems, selecting the most appropriate type of device according to the application, required accuracy, and usage environment is necessary. There is a variety of points to consider in determining which device is best for you.

- Desired measurement accuracy

- Target material and characteristics

- Target shape and application

- Usage environment

- Number of devices to use and installation costs

- Selection According to Desired Measurement Accuracy

- Selection According to Target Material and Characteristics

- Selection According to Target Shape and Application

- Selection According to Number of Devices to Use and Installation Costs

Selection According to Desired Measurement Accuracy

Measurement accuracy varies greatly depending on the measurement system used.

| Desired accuracy | Example measurement system |

|---|---|

| 1 mm units | Scale, measuring tape, ruler |

| 0.1 mm units (100 µm units) | Vernier caliper |

| 0.01 mm units (10 µm units) | Micrometer, dial indicator, displacement sensor/measurement system |

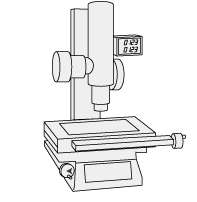

| 0.001 mm units (1 µm units) | Displacement sensor / dimension measurement system, measuring microscope, coordinate measurment machine, Electric micrometer |

The ideal measurement system will vary depending on the range of measurements sought. For those measurements, it's also necessary to look at the capabilities supported by each measurement system, such as whether the results can be viewed with the naked eye, or if the measurements need to be viewed using software.

Selection According to Target Material and Characteristics

Hard/Soft Targets

For targets made from hard material (such as metal), measurement systems that come into direct contact with the target (such as vernier calipers and micrometers) can be used. On the other hand, targets made from soft material (such as synthetic resins) cannot be measured correctly using measurement systems that come into direct contact with the target. Such targets require non-contact measurement systems that use laser beams.

Opaque/Transparent Targets

If a target is opaque, there are a variety of measurement systems capable of measuring the necessary locations. With transparent targets, however, measurement systems must be selected to match the material of the target. For cured resin material (such as plastics), measurement can be performed easily using a micrometer or other contact-type measurement system. For soft targets such as film, a laser displacement sensor or other non-contact measurement system should be used.

Selection According to Target Shape and Application

When selecting a measurement system according to the application, it's necessary to take into account the shape of the target in order to select the most appropriate device.

To find the best measurement method, first look at the intended use.Application Solutions

Selection According to Number of Devices to Use and Installation Costs

When selecting a device, the number of people that will use and the degree of frequency at which those people will use the device at the measurement worksite should also be taken into account. The price and availability of equipment investment should be considered when selecting a measurement system.

Large-scale Measurement System Introduction

Measurement systems frequently used in manufacturing worksites include rules and vernier calipers. Such devices can be used for measurement at 0.1 mm to 1 mm units and have been adopted by many as personal-use measurement systems.

Measurement Systems Used in Particular Processes

Measurement systems are also used for inspections on manufacturing lines, such as for checking the dimensions of molds. Each target will call for different accuracy requirements, so measurement systems should be selected according to the desired accuracy. Generally, measurement systems with higher accuracy tend to be more expensive. With such devices as 3D measurement machines, improvements or modifications to the installation environment may also be necessary.