Types of Measurements Systems

Thrubeam Optical Micrometer

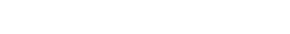

1D Optical Micrometer

- Principle

- Green LED light is emitted as a uniform collimated beam. When a target breaks this beam a shadow is formed on the light receiving element, measuring this shadow gives us an accurate representation of the target.

| (A) Monitor CMOS | The Monitor CMOS tracks workpiece inclination to automatically correct for tilt errors. |

|---|---|

| (B) High-speed exposure CMOS | Proprietary designed measurement CMOS features an integrated amplifier to maximize performance and speed. |

| (C) Target Position CMOS | The CMOS measures the position between the transmitter and receiver |

| (D) High-intensity Green-LED | High-intensity Green LED lasts longer than traditional LED light sources while providing high intensity and evenly-distributed lighting. |

| (E) High performance condenser | Lens unit efficiently focuses LED light |

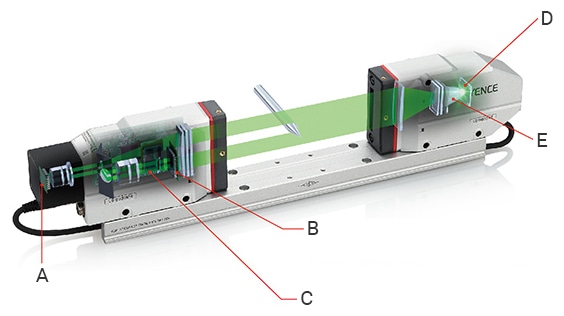

Laser Scan Micrometer

A laser is emitted onto a spinning polygon mirror which traverses the beam throughout the sensors measurement range at a constant speed. Measurements such as the outer diameter are determined by measuring the amount of time the light is blocked from the receiver.

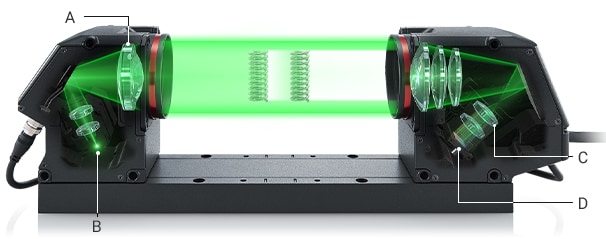

Dual telecentric silhouette-based system

The transmitter emits collimated lighting with a green LED to project a shadow on the CMOS sensor in the receiver.

Measurement is then performed using this captured image. The TM-X5000 Series includes telecentric lenses in both the transmitter and the receiver, ensuring stable, high-accuracy measurement.

- A

- Telecentric lens in transmitter

- B

- High-brightness InGaN green LED

- C

- Telecentric lens in receiver

- D

- High-sensitivity, high-resolution CMOS