Injection Molding Formulas

This page introduces formulas for calculating basic parameters necessary for injection molding. The figures obtained from the calculation are for reference only. The conditions for machining depend on the machine tool you are using. Use the optimal conditions according to your actual machining circumstances.

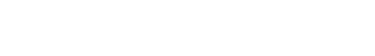

Mold Clamping Force Formula (F: tf)

- p (kgf/cm2): Cavity pressure inside the mold

- A (cm2): Total projection area

- memo

-

This formula is used to calculate the force required to clamp the mold halves during injection molding.

Generally, the cavity pressure inside the mold is within the range of approximately 300 to 500 kgf/cm2. The total projection area is the total of the projected areas of the cavities and runners in relation to the parting surface. Therefore, this value varies depending on the number of items molded and on the runner layout.

Example:

Cavity pressure (P) = 400 kgf/cm2

Projected area for one cavity (A1) = 16.0 cm2

Projected area for runner (A) = 5.0 cm2

In this case, the necessary clamping force (F) is

400 × (16.0 + 5.0) ÷ 1000 = 8.4 (tf).

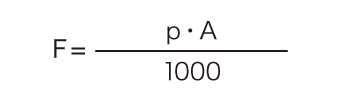

Molding Shrinkage Calculation (s)

- lc (mm): Mold dimensions

- l (mm): Molded product dimensions

- memo

-

This formula is used to calculate the molding shrinkage from the mold dimensions and the product dimensions.

Plastic materials expand in volume under high temperatures and shrink under low temperatures. For this reason, the molds are designed to be larger than the molded products. The difference between the dimensions of the molded product and those of the cavity of the mold is expressed by the molding shrinkage ratio.

Example:

Mold dimensions (lc) = 400 mm

Product dimensions (l) = 399 mm

In this case, the mold shrinkage ratio (s) is

100 × (400 - 399) ÷ 400 = 0.25(%).

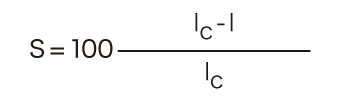

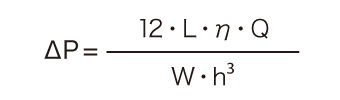

Pressure Loss (ΔP: Pa)

- For runners with circular, semicircular, or oval cross-sections

-

- η (cP): Viscosity

- Q (m/s): Flow rate

- L (m): Length

- R (mm): Hydraulic radius

- S (mm2): Cross-section area

- ℓ (mm): Circumference of cross-section

- For rectangular cross-sections

-

- η (cP): Viscosity

- Q (m/s): Flow rate

- L (m): Length

- W (mm): Width

- h (mm): Thickness

- memo

-

This formula is used to calculate the pressure loss in a sprue, runner, or gate. The equation shows an example of calculating the pressure loss with the assumption that the resin is a Newtonian fluid.

You can see that pressure loss is largely attributable to the thickness and diameter of the cross-section.