Forming Machines

1. Overview and Characteristics

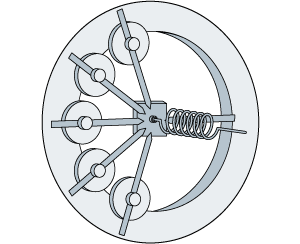

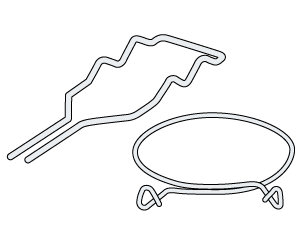

Equipped with machining devices capable of stamping, bending, and cutting, a forming machine can continuously manufacture parts like springs, clips, rings, and coils from wire materials and band plates.

Before the emergence of forming machines, parts needed to be finished through numerous processes after the wire material was cut. This caused increased material waste and longer processing times.

In contrast, forming machines draw out the necessary length of coil material and automatically process it into the desired part at high speeds. Forming machines can also use materials without any waste and can continue manufacturing with no changeovers.

2. Applications and Evolution

Today, metal parts produced by forming machines cover a diverse range of products, including automobile parts, electric and electronic components, metal building materials and fittings, and stationery.

The specialized forming machines used to manufacture springs are called wire forming machines or spring forming machines.

In recent years, forming machines have increasingly adopted numerical control (NC) and multi-functionality in order to manufacture parts with complex shapes precisely and quickly using servo motor control. Furthermore, some newer models offer all-inclusive functions that range from bending to riveting and welding to assembly.