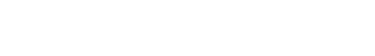

Dies (molds)

1. Overview and Classification

Molds and dies are tools that are essential to mass production in present-day manufacturing. Both are key elements in manufacturing―for example, molds are used in injection molding to shape resin as well as in casting, and dies are used in stamping. Today’s techniques are able to create micron-order precision molds and dies, contributing to the mass production of products with the same shape and quality in a wide range of areas.

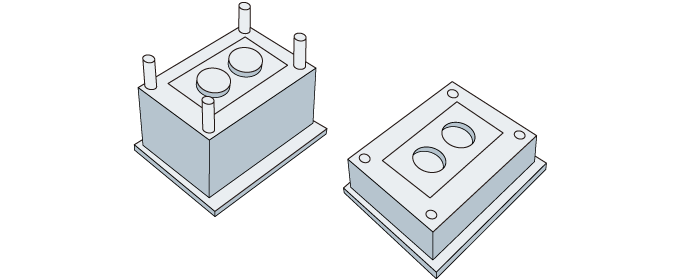

Dies and molds are both tools for shaping. Dies are used to shape sheet metal and other metal forms. A typical application is the making of automobile body parts. On the other hand, molds are used in injection molding such as with melted resin or casting molten metal.

2. Die and Mold Machining

Materials for dies and molds include tool steels with carbon or chromium content, as well as die steel, high-speed steel, and cemented carbide. Recently, ceramics have also been adopted as a material. Materials used for dies and molds are mostly hard and difficult to cut. For this reason, dies and molds are cut using machining centers or other NC machining tools, but the products generally go through subsequent processes such as grinding for added precision.

Furthermore, electrical discharge machining is used to produce dies and molds with even greater detail. Electrical discharge machining uses sparks from an electrical discharge to melt the surface of the workpiece during machining. Not only is this method capable of producing precision metalworking, it also supports the creation of complex three-dimensional shapes.

3. Die and Mold Manufacturing Today

The proliferation of machining centers makes it seem like die making is possible for anyone with the right equipment. However, die manufacturing is still considered a high-skill task due to the need to have techniques and skills that cover the entire process, including CAD designing, the selection of materials and machining methods, and performing minute machining that cannot be done through automated procedures.

Furthermore, even shorter turnarounds for die delivery are requested nowadays as product lifecycles are shorter and production includes smaller lots of numerous items. On another note, the emergence of 3D printers is expected to drastically change the way dies and molds are manufactured. Today, further innovations in mold and die technology are imperative.