PCs/PCBs

This page introduces network connection examples for PCs and PCBs as well as connection examples using KEYENCE’s KV-XLE02 Ethernet unit.

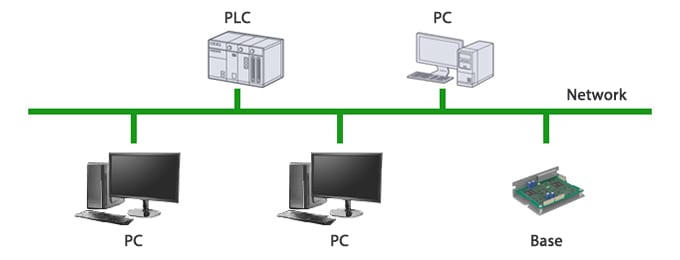

Network example

Connecting PCs and PCBs to a network can be done using Ethernet or any other supported open network connection.

- Network-compatible units or connection interfaces are required for PLCs, PCs, and PCBs.

KEYENCE Ethernet units

Most PCs and PCBs support Ethernet communication. KEYENCE’s KV-XLE02 Ethernet unit and PROTOCOL STUDIO Ethernet communication setup software make communicating with PCs, PCBs, and other equipment incredibly simple.

Ethernet UnitKV-XLE02

| Hardware |

Ethernet

|

Communication speed: 1 Gbps

|

2-port

|

|---|---|---|---|

| Functions |

EtherNet/IP®

|

EtherCAT*1

|

CC-Link IE

Field*2 |

|

PROFINET*3

|

PLC link

|

PROTOCOL STUDIO

|

|

|

Sensor

applications |

Modbus/TCP

clients/servers |

FTP clients/

FTP servers |

|

|

KV socket

|

Host link

|

MC protocol/SLMP

|

|

|

Mail sending/receiving

|

Unit interrupt

|

Inter-unit synchronization

|

- Slave

- Intelligent device station

- Device

Supporting the creation of communication protocols for a wide range of devices PROTOCOL STUDIO

Completely ladder-less equipment communication

- Simply select the communication format and command settings in the tool.

- Automatic communication schedule adjustment within the unit

- Simple rearrangement of sending and receiving processes into flow format

- Serial communication support When used with the KV-XL202/XL402

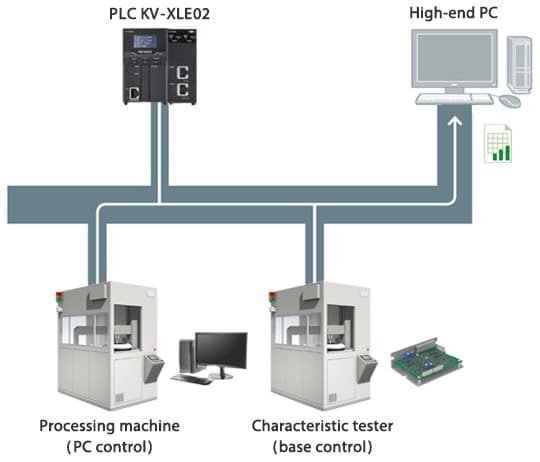

Typical connection example

Connecting to a network makes it possible to collect and manage various information from PCs and PCBs. This allows for the construction of systems for changeovers, production management, and more.

The following example includes network-connected PCs and PCBs.

Utilize Ethernet connectivity for centralized management of product processing conditions and production information.

Utilizing Ethernet communication with PCs or PCBs used for controlling equipment makes it possible to perform various operations—including reading and changing processing conditions and production information—all at once. Product information traceability is also possible by uploading data to a host PC using FTP.