Level Sensors

This page introduces KEYENCE’s lineup of level sensors in addition to the supported networks and connection examples.

- Level sensor lineup

- Connection example

- Network example

- Supported networks

- Typical connection example

Level sensor lineup

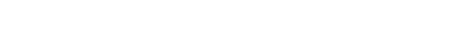

NQ Series network communication module

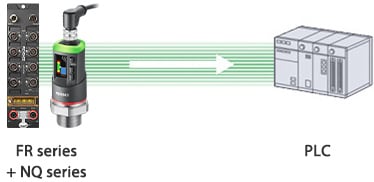

Connection example

FR Series network communication modules can be used to connect level sensors.

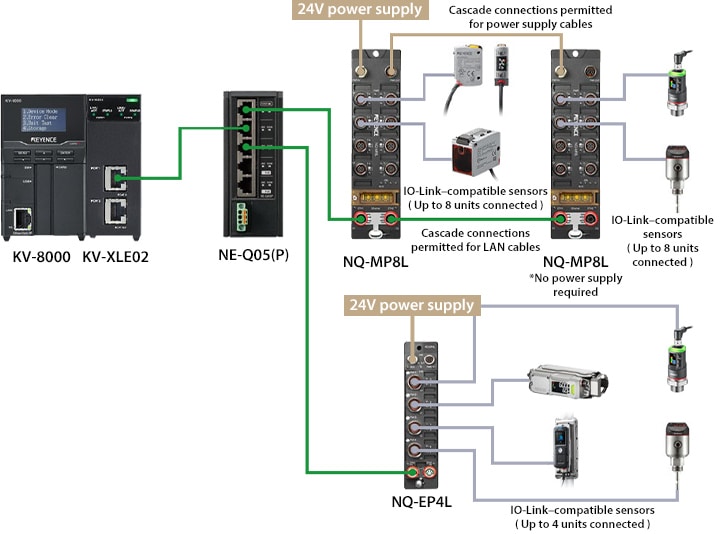

Network example

- A network-compatible unit or board is required for PLCs and PCs.

Supported networks

| Series | Field network | Other communication functions | |||||||

|---|---|---|---|---|---|---|---|---|---|

| EtherNet/IP® |

DeviceNet® |

CC-Link | IO-Link | PROFINET |

PROFIBUS |

EtherCAT® |

Ethernet TCP/IP |

RS-232C RS-422A/485 |

|

| Radar Level Sensor FR Series |

Field network

✓

(MP-FEN1,NU-EP1) |

✓

(NU-DN1) |

✓

(NU-CL1) |

✓

(NQ Series) |

※

|

※

|

✓

(NU-EC1A) |

Other communication functions

—

|

—

|

| Sensing Guide Pulse Level Sensor FL Series |

Field network

—

|

—

|

—

|

✓

(NQ Series) |

—

|

—

|

—

|

Other communication functions

—

|

—

|

- Click here to contact KEYENCE regarding PROFINET and PROFIBUS connections.

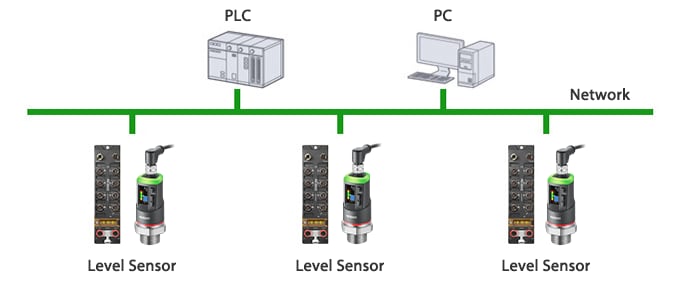

Typical connection example

Connecting to a field network makes it possible to collect and manage various information from pressure sensors. This allows for the construction of information systems for batch monitoring of liquid levels at various locations, predictive maintenance, changeovers, quality management, and more.

The following example includes a network-connected level sensor.

Remote monitoring using digital data

Real-time remote monitoring makes it possible to obtain accurate liquid level information from tanks located off-site. This allows for quicker responses to problems, leading to reduced downtime.