Code Readers

This page introduces KEYENCE’s lineup of code readers in addition to the supported networks and connection examples.

Code reader lineup

Code readers

-

AI-Powered Code Reader

SR-X Series

-

1D/2D Code Reader

SR-2000 Series

-

Autofocus

1D/2D Code Reader

SR-1000 Series

-

Logistics Code Reader

SR-5000 Series

-

High Performance Compact 1D and 2D

Code Reader

SR-750 Series

-

Ultra-Compact 1D and 2D Code Reader

SR-700 Series

-

Handheld DPM Code Reader

SR-G100 Series

-

Ultra Small Digital

Barcode Reader

BL-1300 Series

-

Long-distance Laser

Barcode Reader

BL-700 Series

-

Ultra Small CCD

Barcode Reader

BL-180 Series

-

Handheld Code Reader

HR-100 Series

Main communication units

Connection example

Connecting the SR-X Series and SR-2000/1000/750 Series to a network requires a dedicated cable.

RJ-45 connector

(Ethernet, EtherNet/IP®, PROFINET)

9-pin D-sub / Strand wire

(RS-232C)

Connecting the SR-700 or BL-1300/700/180 Series to a network requires a communication unit compatible with the specific series and network.

Communication unit

Network

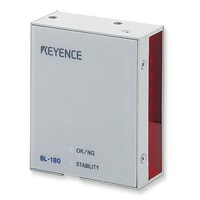

Network example

- A network-compatible unit or board is required for PLCs and PCs.

- A 1:1 connection is used for connections via RS-232C.

Supported networks

| Series | Field network | Other communication functions | |||

|---|---|---|---|---|---|

| EtherNet/IP® |

PROFINET |

Ethernet TCP/IP |

RS-232C*1 RS-422A |

USB*2 | |

| AI-Powered Code Reader SR-X Series |

Field network

✓

|

✓

|

Other communication functions

✓

|

✓

|

✓

(SR-UR1) |

| 1D/2D Code Reader SR-2000/1000/750 Series |

Field network

✓

|

✓

|

Other communication functions

✓

|

✓

RS-232C |

✓

(OP-87533 + NX-CD2M + N-UB) |

| Logistics Code Reader SR-5000 Series |

Field network

✓

|

✓

|

Other communication functions

✓

|

✓

(SR-BX1/ SR-BX2) |

✓

(SR-UR1) |

| Handheld DPM Code Reader SR-G100 Series |

Field network

✓

(SR-LR1) |

✓

(SR-LR1) |

Other communication functions

✓

(SR-LR1) |

✓

RS-232C (SR-LR1) |

✓

(SR-UB1) |

| 1D/2D Code Reader SR-700 Series |

Field network

✓

(N-L20) |

✓

(N-L20) |

Other communication functions

✓

(N-L20) |

✓

RS-232C /RS-422A (N-R2/R4) |

✓

(N-UB) |

| Barcode Reader BL-1300 Series |

Field network

✓

(N-L20) |

✓

(N-L20) |

Other communication functions

✓

(N-L20) |

✓

RS-232C /RS-422A (N-R2/R4) |

✓

(N-UB) |

| Barcode Reader BL-700/180 Series |

Field network

—

|

—

|

Other communication functions

✓

(N-L1) |

✓

RS-232C /RS-422A (BL-U1 /BL-U2 /N-42) |

✓

(N-UB) |

| Handheld Code Reader HR-100 Series |

Field network

—

|

—

|

Other communication functions

✓

(N-L1) |

✓

RS-232C (HR-1C3RC) |

✓

RS-232C (HR-1C3UN) |

- PLC link connectivity of PLCs made by various other manufacturers is possible via RS-232C/Ethernet.

- Serial communication can be used via USB when connected to a PC.

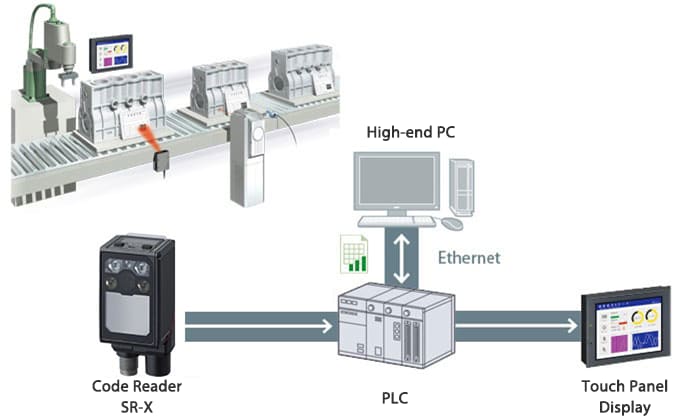

Typical connection example

Connecting to a network makes it possible to collect and manage various information from code readers. This allows for the construction of information systems for checking marking quality, changeovers, production management, and more.

The following example includes a network-connected code reader.

Serial code management for small-lot, multiple-variety production

Automatic product type identification is possible by reading the serial code on the production instructions. The operation details for each product type are shared from the PLC to each device (touch panel, laser marker, robots, etc.). This helps prevent errors during small-lot, multiple-variety production on a single line. Connecting the PLC to the host PC makes it possible to centrally manage operation details and production results directly on the host PC.