Sensing Guide Pulse Level Sensor

FL series

Sensing Guide Pulse Level Sensor FL series

Offers Stable Liquid Level Detection in Any Condition

- Industry first sensing guide pulse method

- Build-up resistant

- Unaffected by foam or bubbles

- Ignores obstacles in environment

- Detects any liquid (water, oil, chemicals, etc.)

- Eliminates all factors of false detection

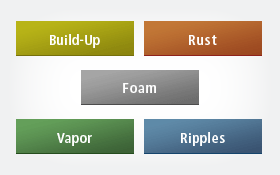

Unaffected by: Build-Up / Foam / Ripples / Vapor

The FL Series is the industry's first sensing guide pulse liquid level sensor. The new TriSense technology allows for detection of any liquid while also automatically adjusting for both the external environment (ex. waves, foam, etc.) and condition of the probe (ex. build-up).

Features

Stable Detection at All Times

The new "Sensing Guide Pulse Method" allows for the detection of liquids while ignoring obstacles in the environment. This is achieved while also automatically adjusting to account for build-up.

Conventional Issues Eliminated

The FL Series solves all problems of conventional level sensors that lead to false detection. This helps prevent costly downtime from situations such as boil-dry, tank overflow, or unintended liquid depletion.

Integration Simplified

These devices have an immediate startup process to save valuable time on initial setup. Various models with multiple output options are available. These allow for stable detection in any environment.