Safety Controller

A safety controller that is compatible with multiple industrial communication protocols and connection capability with various general-purpose PLCs. To program on this model, just select the input devices and application. Even first-time users can easily install and operate this safety controller that complies with the Category4 and PLe standards.

Product Lineup

The GC Series consolidates any and all safety controls into one simple device. Although the GC Series can connect to any device, the GC-Link feature greatly reduces wiring when connecting to any KEYENCE safety product. Plus, the built-in display and dedicated software make setting up safety controls systems easier than ever.

Features

Easy Integration

Universal Connectivity

The GC Series easily integrates ANY safety device into one easy-to-use system. This safety controller provides flexible connection options for everything ranging from primary safety devices to auxiliary devices (reset buttons, muting sensors, etc.).

GC-Link Advantage

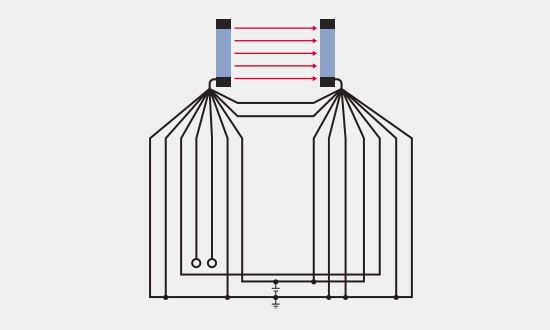

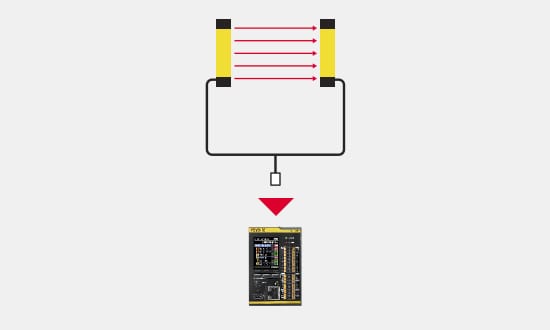

Safety wiring has never been easier or more mistake-proof than with the innovative GC-Link feature. When utilizing the GC Series with any KEYENCE safety device, wiring can be reduced to a single quick-connect cable.

Conventional Wiring

GC-Link Connection

Intuitive Software

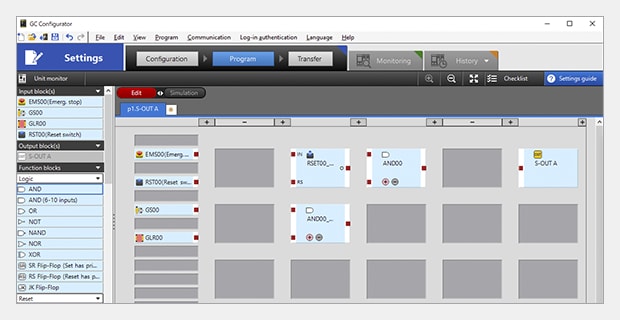

The dedicated software of the GC Series provides an abundance of features designed to simplify the programming process, including its automatic terminal assignment, drag-and-drop interface, easy & simulation modes, etc.

Set up program in seconds

Safety controllers are capable of starting and stopping equipment based on signals from safety input devices. They also support additional safety inputs/outputs and can be used for safety control of equipment. Safety controllers are designed based on functional safety standards. They are verified safety devices made up of electronic circuits and software.

Benefits of Safety Controllers

Safety controllers monitor other safety devices and are designed to shut off the power to a hazard when needed. Increasing the number of safety inputs and outputs can help reduce wiring and footprint. Safety controllers are devices that conform to international safety standards.

Based on signals from safety devices such as safety interlock switches and safety light curtains, safety controllers shut off the power to a hazard. This includes processing machines, robots, and conveyor systems. These devices also disable startup and operation of a hazard until a safe condition has been confirmed. In the event of an internal problem, safety controllers detect the problem through a self-diagnostic function and turn off the safety outputs.

Safety controllers also support additional safety inputs and outputs. This can mean reduced wiring and a smaller footprint compared to setups with multiple safety relay units. In addition to being certified for conformity with international safety standards (ex. Category 4, PLe, and SIL3), safety controllers can be free from performance deterioration that occurs with use, unlike safety relay units that have mechanical contacts.

In contrast to safety relay units, which are used to build simple safety control circuits, safety controllers are programmable. This means they support development of flexible safety systems for complex applications.

Safety systems only using force guided relays and safety relay units do not easily accommodate complex safety controls or the adding of additional safety devices. Because safety controllers are programmable, they offer flexibility and freedom. Meaning, they support safety controls that are becoming increasingly complex, as well as reduce the time spent on design and integration.

Some recent safety controllers even come equipped with a programming tool that allows for easy "drag and drop" setup. Features like this allow users to easily program a safety system without the need for specialized skills. This significantly reduces installation and startup time.

Most safety controllers support common industrial networks for seamless coordination with general-purpose PLCs.

Safety controllers support EtherNet/IP🄬, among other network protocols, and can connect to different general-purpose PLCs produced domestically and abroad. In most cases, the safety control circuit and the overall system’s control circuit are independent from each other. This means the operating status of the safety controller must be monitored on a general-purpose PLC that controls the entire system. This is possible with just a single LAN cable and a connection to an industrial network.

Safety Controller Case Studies

Safety measures for rolling machines

Safeguards in and around a safety fence can be achieved by installing a GS-50 Series safety interlock switch on the door of the safety fence. The inside of the fence can be monitored by a SZ-V/SZ Series safety laser scanner.

The safety interlock switch can be configured to unlock the door only after the rolling machine has stopped. Restarting of the rolling machine would only be allowed after the operator finishes their task, leaves the safety fence, and locks the door behind them. The safety laser scanner ensures no other workers are inside the fence. After the machine is stopped and a worker enters the fence, the safety laser scanner detects the worker. While the worker is inside the fence, startup is disabled. The GC Series safety controller can be used to easily tackle anything complex.

Safeguard for six-axis robots

With a SZ-V/SZ Series safety laser scanner, you can set up two protection zones with a single unit. You can attach a safety laser scanner to a six-axis robot and control it so the robot decelerates in the first protection zone and stops in the second protection zone.

Using a GC Series safety controller not only allows for safe and easy connection with safety devices, it can also perform integrated monitoring of such devices. An enable switch can be used to switch the robot to teaching mode or to temporarily disable the safety mechanism.

Safety precautions for SCARA robots (horizontal multi-joint robots)

With a GS Series safety interlock switch monitoring the door, place a GL-R/GL-S Series safety light curtain in the path between equipment. The safety interlock and light curtain can be easily connected to a GC Series safety controller. Using the safety controller makes it easy to connect the safety devices and allows for simple setup of the robot’s start and stop conditions through programming. When using multiple SCARA robots, a setup can be easily made to stop the SCARA robot in the front when the safety light curtain is interrupted and stop all robots when the door is opened.

This site includes information on machine safety standards and managing risk. Learn about ISO international standards, risk assessment, and other important safety topics.

Frequently Asked Questions About Safety Controllers

The GC Configurator software can be downloaded free of charge from the KEYENCE website. This software has an EASY mode, which doesn't require any real programming―you only need to select your input devices and application. Safety controls created using EASY mode can sufficiently replace conventional control systems built from multiple safety relay units. Even users new to safety controllers can operate them with ease.

STANDARD mode offers more flexible control but without a learning curve, as users only need to place and connect function blocks.

The GC Series uses GC-Link, the quick-connecting wire-saving interface for KEYENCE’s safety sensors. In other words, the wiring is done for you. An additional benefit with GC-Link is that it can actually monitor the strength of each beam on a safety light curtain. An alert can be assigned if the intensity level is low. There is also a function that monitors the operating status of each safety interlock switch, even when connected in a cascade.

GC-Link is supported by GL-R/GL-S Series safety light curtains, SZ-V/SZ Series safety laser scanners, and GS Series safety interlock switches.

The GC-1000 supports five communication protocols (EtherNet/IP🄬, MC protocol, Modbus/TCP, PROFINET, and UDP), so it is compatible with a variety of general-purpose PLCs.

This guidebook introduces a wide range of safety information, including machine safety standards (for manufacturing equipment and other machines), the Performance Level (PL) classification used for defining risk assessment and safety factors, and specific safety devices.