UV Laser Coder

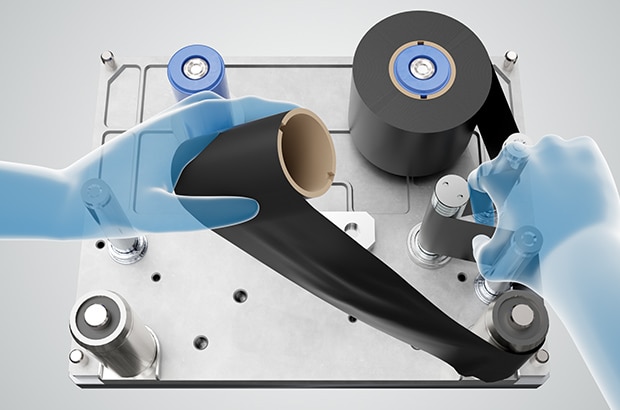

UV laser coders use UV light to create a mark on packaging film via a chemical reaction with Titanium Dioxide, a widely used pigment, instead of the traditional method of using thermal pads/ribbons of thermal transfer printers (TTO). UV laser coders eliminate costly consumables of TTO, and downtime required from frequent stoppages due to ribbon and printhead replacement.

Product Lineup

UV Laser Coders are designed as a direct replacement for thermal transfer overprinters (TTO). This light-based marking eliminates the need for ink ribbons required to transfer ink to the surface of the film with conventional thermal printers. The result is permanent, highly visible and damage-free marking without the need for special films.

Features

No Down Time

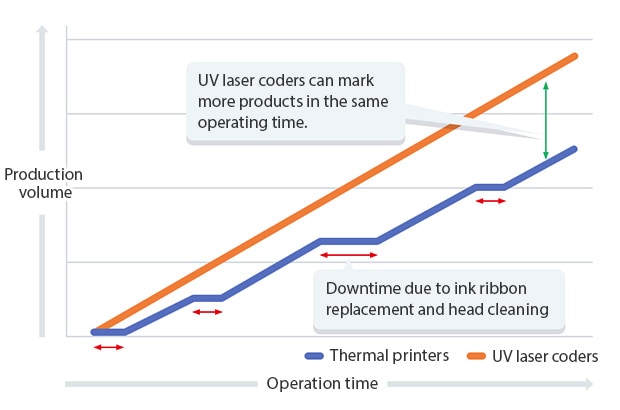

Light-based marking with a UV laser coder eliminates the downtime required to replace ink ribbons and clean heads with conventional thermal printers.

With no downtime, Overall Equipmenet Effectiveness (OEE) can be improved, helping increase production throughput.

No Consumables

Because marking with a UV laser coder is based on light, regular replacement of parts is not necessary and consumable costs can be eliminated.

No ink ribbon costs

The FP-1000 Series is a 1.3 W UV laser with a 120 x 120 mm 4.72″ x 4.72″ marking area. It outputs 355 nm light for high contrast codes on films with a stand-off distance of between 0-20 mm 0″-0.79″ or 40-60 mm 1.57″-2.36″. This laser was designed from the ground up for high-speed film coding applications traditionally accomplished with thermal printers (TTO). The groundbreaking design of the FP-1010 marking head is compact, allowing it to be easily retrofitted into existing TTO mounting. With maximum line speeds of up to 4000 mm/s 157.48″/s (787.5 ft/min), it is here to make TTO printers obsolete. You also get all the benefits of UV light for half the cost with the FP-1000. For more information, check our product brochure.

UV laser coder machines have a wide range of industrial applications due to their ability to replace thermal (TTO) printers to eliminate consumables and downtime. A UV laser coder can mark on a wide range of materials without heat, contact, or consumables, making them incredibly versatile and suitable for use in the following industry examples:

Food and Beverage

・Packaged Foods

・Beverage

・Baked Goods

・Candy and Confectionary

・Pet Food

・Snacks

・Fruits and Vegetables

Consumer Products

・Cosmetics

・Personal Care

・Nutraceutical

・Pharmaceutical

・Home Care

・Chemicals

Frequently Asked Questions About UV Laser Coders

A UV laser coder, also known as a UV laser marker, is a type of industrial laser marking machine that relies on a UV laser to mark or print onto a substrate. As such, it eliminates the need for ink ribbons and thermal pads associalted with traditional thermal transfer overprinters and their costs.

The main benefit of UV laser coders is the high-quality mark that is completely permanent while doing zero damage to substrates. This is all possible because of the high absorption rate of UV light and the photolytic reaction to create a contrast that does not thermally damage the surface of the marked substrate.

In many cases, the FP-1000 can also significantly reduce production costs due to the lack of downtime and consumables required.

Traditional thermal printers (TTO) require ribbons, print heads, and other consumable mechanical parts. Time to complete maintenance, troubleshoot issues, re-work from poor marks or missing marks, and replace consumables results in frequent interruptions in production. UV laser coders require zero maintenance and no consumables and ensure repeatable permanent marks.

By passing Traditional IR laser light (1064 nm) through a crystal or medium doped with rare earth elements, the laser generates UV

light, which is then focused by using a system of mirrors and a focusing lens and directed onto the surface of the substrate.

When the focused UV laser beam hits the material’s surface, it causes a photochemical reaction, which changes the affected material without generating heat—unlike IR lasers, which create contrast/changes in the material via thermal marking or burning the substrate.

UV laser marking is often called "cold marking" due to the lack of heat or thermal damage done during the marking process. This allows UV laser coders to excel in applications where substrates are heat sensitive or cannot be damaged.

UV laser marker technology can print on various materials; however, the printing process and results may vary depending on the type of material being used. In the case of Keyence's FP (film printer) series, the printers are specifically designed for printing on film. Film is a commonly used material in industries such as food, packaging, and medical devices.