3D Surface Profiler

A non-contact 3D surface profiler designed to capture SEM-like images and perform high-resolution profile, roughness, and film thickness analysis. For the first time, nanometer, micrometer, and millimeter measurements can be performed on any target, regardless of shape or material.

Product Lineup

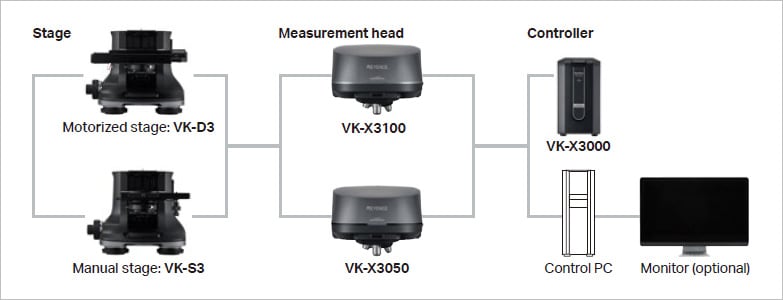

The VK-X3000 3D Surface Profiler uses a triple scan approach, where laser confocal scanning, focus variation, and white light interferometry measurement methods are used, so that high-accuracy measurement and analysis can be performed on any target. The VK-X3000 has a resolution of 0.01 nm and can scan areas up to 50 × 50 mm (1.97″ × 1.97″), allowing for measurement of the overall shape of the target while still maintaining high-resolution for analysis of minute surface features. KEYENCE's new 3D Surface Profiler can handle any target, including those with transparent or mirrored surfaces, large height changes, or steep angles.

Features

Optical Profiler Basics

Observation

Extensive magnification coverage, ranging from optical microscopes to SEMs

- Magnification up to 28,800×

- Automatic focusing

- Observe any material

Measurement

Instant, non-contact surface scanning

- No target damage

- Accurate nano-level measurement

- Compatible with any shape or material

Analysis

Unprecedented surface characterization

- Quantification of even the most detailed shapes

- Differentiate surfaces easily

- Roughness analysis

Precise Scanning Unaffected By Material and Shape

- Accurately measure steep slopes and angled surfaces

- Best-in-class XY resolution ensures even the smallest features are captured

- No data dropout on transparent or highly-reflective surfaces

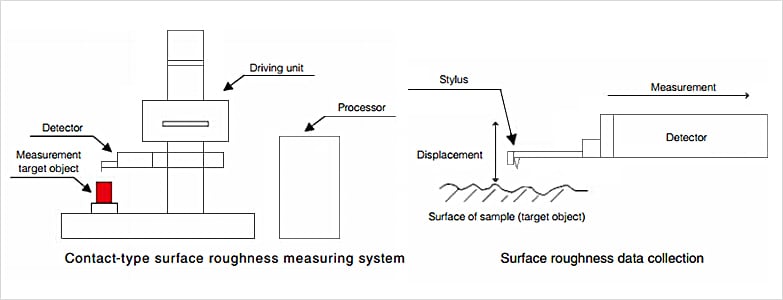

A surface profiler is an instrument that captures 3D data on the surface of a target, typically for measuring surface roughness. Surface profilers can use a stylus probe, white light, a laser, or other methods as a means to capture data. Conventionally, stylus probes made of diamond were used, however most industries are shifting to optical systems due to the surface being scratched, and potentially damaged, when using a physical stylus probe.

Common applications for surface profilers include checking for wear on metal surfaces, checking cut surfaces, and checking painted/coated finishes.

How to Use a Surface Profiler for Measuring Surface Roughness

1. With a contact-type surface profiler, surface roughness is measured by tracing the probe across the surface of the target. In contrast, a laser-based non-contact surface profiler emits a laser beam onto the target and detects the reflected light to measure the roughness.

2. The direction of measurement is the key to successful measurement. For example, a processed metal product is generally measured perpendicularly to the processing direction so that the profiler can capture the surface characteristics more reliably.

3. Measurement speed is also a key element for accurate measurement. Measurement is first performed slowly, and the speed is increased until no fluctuation occur in the measured values.

Benefits of 3D Surface Profilers

3D measurement systems fall within two main categories: contact and non-contact systems. Contact systems utilize a probe or stylus that physically makes contact with the surface being measured. The VK-X Series is a non-contact measurement system, that overcomes common limitations of contact systems.

Contact systems generally suffer from several limitations, including causing damage to certain surface types, inability to measure viscous or adhesive materials, and an inability to measure surface features smaller than the tip of the stylus. Because the VK-X Series is a non-contact measurement system, there are no issues in regards to damaging a sample, or difficulty measuring adhesive or viscous materials. Additionally, the VK-X is equipped with a laser with a beam spot radius of 0.2 micron, enabling even the smallest surface features to be detected.

Optical microscopes are generally the standard for imaging, but these systems have a shallow depth-of-field and limited spatial resolution (approximately 500 nm). On the other end of the spectrum, SEMs can provide extremely high resolution and magnification, but can only produce monochrome images and are unable to view larger objects without destroying them. Additionally, SEMs are difficult to operate, and require samples to be coated in a conductive material and scanned within a vacuum. KEYENCE's 3D Surface Profiler can capture high-definition color images at up to 28800x magnification.

The VK-X is equipped with a white light source and a laser source in conjunction with a focus stacking algorithm, enabling high resolution, fully-focused images to be captured. Additionally, because a laser is used, a spatial resolution of 120 nm can be achieved. From an operation standpoint, the VK-X series requires no sample preparation, and even large objects can be accommodated for non-destructive imaging.

Many measurement systems use a single measurement principle to obtain data from a target. While this allows the system to be used for the measurement of some targets, others targets will require the use of a different measurement system. For example, white light interferometers struggle to obtain data on very rough surfaces, or surfaces with steep angles. In this instance, the user would be required to use a laser confocal microscope to obtain accurate data on the target.

Equipped with laser confocal scanning, white light interferometry, and focus variation, KEYENCE’s 3D Surface Profiler can measure nearly any target. Measurement and analysis can be flexibly performed from the millimeter scale to the micrometer and nanometer scale. Typically, users would need three different measurement systems to measure such a wide-range, but KEYENCE's triple scan approach allows for nearly any target to be measured with just one device, no matter the material or shape.

Stylus-Based Surface Profiler for Roughness Measurement

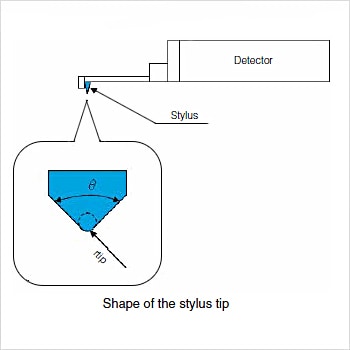

With contact-type surface roughness instruments, a stylus tip makes direct contact with the surface of a sample. The detector tip is equipped with a stylus tip, which traces the surface of the sample and electrically detects the vertical motion of the stylus.

The electrical signals go through an amplification and digital conversion process to be recorded.

To precisely measure delicate shapes and roughness with a contact-type surface roughness tester, the radius of the stylus tip must be as small as possible with low contact pressure.

Styluses are made of sapphire or diamond, and their tip radius is usually about 10 μm 0.39 mil or smaller. A conical shape with a ballpoint tip is considered ideal for a stylus.

Tip radius: r tip = 2 μm 0.08 mil, 5 μm 0.20 mil, 10 μm 0.39 mil

* Cone taper angle: 60º, 90º

* Unless otherwise specified, cones have a 60º taper.

Stylus-Based Surface Profiler Characteristics

Contact-type surface roughness testers provide reliable measurements because they directly touch the sample. However, direct contact to a sample often has many disadvantages as outlined below.

Advantages

- Clear wave profile

- Capable of long distance measurement

Disadvantages

- Stylus wear

- Measuring pressure can cause scratches on the sample surface

- Inability to measure viscous samples

- Measurement limited by radius of stylus tip

- Time consuming

- Difficulties in positioning and identification of subtle measuring points

- Requires sample cutting and processing for tracing by the detector

Non-Contact Surface Profiler for Roughness Measurement

A non-contact measuring instrument uses light in place of the stylus of used in a contact-type measuring instrument. These instruments come in multiple types, such as confocal and white light interference, and vary depending on the principle used. There are also a variety of contact-type detectors that have been changed into non-contact instruments by replacing the probe with optical sensors and microscopes. We will use KEYENCE's 3D laser scanning microscope, the VK-X Series, as an example to explain the principles of confocals.

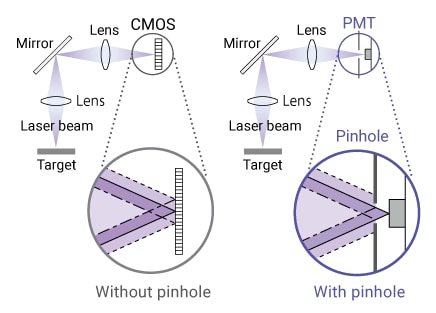

A 3D laser scanning microscope uses the confocal principle, and a laser as the light source, to measure the asperity of the target's surface.

With KEYENCE's VK-X Series, an X-Y scanner is embedded in the measurement unit. The laser light source scans across the surface of the target in the X and Y directions and acquires the surface data.

The scanning principles are explained below.

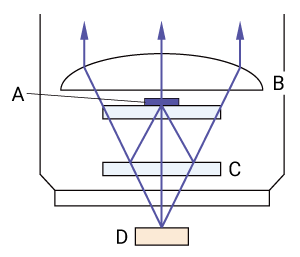

Laser confocal scanning measurement principle

Laser microscopes utilize a special optical system consisting of a light source, a light receiving element (PMT), an objective lens, a half mirror, and a pinhole in order to perform both magnified observation and surface shape analysis.

The laser light generated by the light source is concentrated at the focal point by the objective lens, with the measurement target also being placed at the focal point. The laser light then reflects from the target surface and passes through the objective lens and is focused once more. A pinhole is situated at the focal position, directly in front of the light receiving element. The focused light passes through the pinhole, and all the reflected light enters the light receiving element.

When the target is at a position that is out of focus, the laser light is not concentrated and a portion is blocked by the pinhole, reducing the amount of light that reaches the light receiving element.

Laser microscopes detect whether the sample is at the focal position according to the intensity of the reflected light that returns to the light receiving element. An optical system which incorporates a pinhole in front of the light receiving element is known as a confocal optical system, and the detection principle is known as the "confocal principle."

Laser confocal scanning methods

Some typical methods of scanning used in laser microscopes are a Galvano scanner, an acousto-optic device (AOD), or a Nipkow disk.

Galvano scanner method:

Mirrors that reflect laser light are attached to the end of servo motors. The servo motors are controlled to change the angles of the mirrors, which causes the laser to scan in the X and Y directions. While this approach can produce high data quality, scanning takes time.

Acousto-optic device (AOD) method:

This method uses an acousto-optic device, which is an acousto-optic medium made of glass to which a piezoelectric element has been attached. By applying an electric signal to this piezoelectric element, ultrasonic waves are generated. These waves diffract laser light that passes through the acousto-optic medium. While the scanning speed is fast, the data obtained is prone to distortion.

Nipkow disk method:

A disk with one or more rows of pinholes arranged in a spiral is spun, and the multiple beams of light passing through the pinholes scan across the sample surface. While this method can produce relatively high data quality, observation of samples with low reflectivity is difficult.

Additional measurement principles

In recent years, advanced 3D surface profilers that combine multiple different measurement principles have garnered increasing attention. By combining multiple measurement principles into one device, each measurement principle's weak points can be compensated for. Keyence's VK-X3000 Series 3D Surface Profiler integrates three different principles in a single unit: white light interferometry, laser confocal scanning, and focus variation. This makes it possible for a single unit to measure and analyze a variety of targets, regardless of their material, shape, or surface conditions.

Principle of white light interferometry:

White light interferometry captures 3D shape data through the observation of light interference patterns using an image sensor, such as a CMOS. Using an interference objective lens with a built-in reference mirror, white light from an LED or other light source is used to illuminate the reference mirror and the target (measurement surface). The light reflected from each object interferes with one another, and the interference pattern appears as contour lines at each half wavelength. This corresponds to the shape of the target surface with respect to the reference mirror. The interference stripe is then captured by the image sensor and processing is used to determine the 3D shape of the target.

A: Reference mirror, B: Objective lens, C: Beam splitter, D: Sample

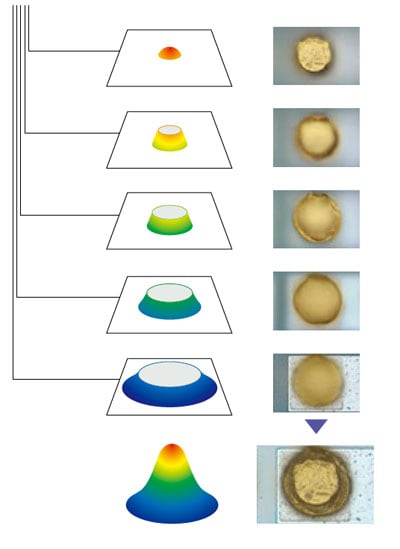

Principle of focus variation:

A high-resolution image sensor is used to determine the focal point for each pixel by detecting focal changes (i.e. the degree of blur in an image). To detect focal changes, multiple images of the target are captured while the lens moves in the Z direction. For in-focus images, the difference in brightness between adjacent pixels increases proportionally to the image brightness. However, if the image is not in focus, the difference in brightness between adjacent pixels becomes small. This makes it possible to obtain the height information for a target by recording the lens position at the point with the greatest difference in brightness.

Non-Contact Surface Profiler Characteristics

In addition to the points that have already been explained, the characteristics of non-contact types can be summarized as shown below.

Advantages

- No sample surface damage

- Able to measure smaller changes than contact types

- Quick measurements

- Simultaneous observation of surface image and height profile

- Able to acquire high-definition, fully-focused images that rival those of SEMs

Disadvantages

- Limited measurement target size

3D Surface Profiler Case Studies

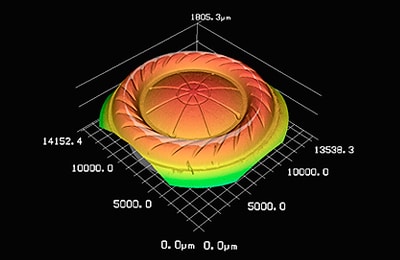

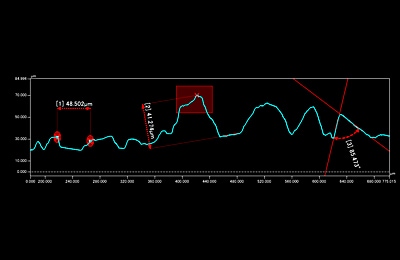

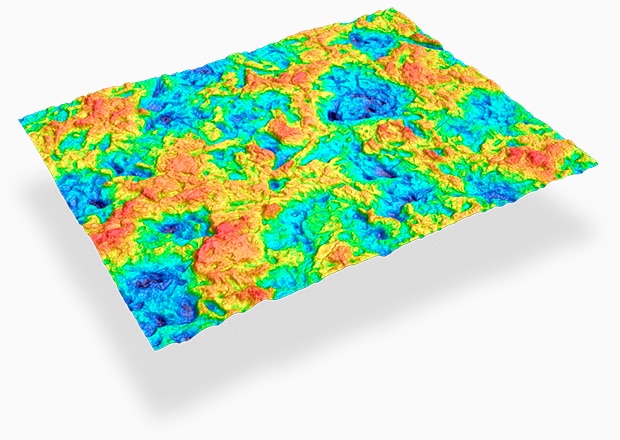

Surface roughness measurement

Surface roughness has many standardized parameters; the more the parameters, the more complicated measurement becomes, which tends to mean more time spent to complete an evaluation. Quantification on its own is not sufficient to make a judgment, and pass/fail tests and quality control can be challenging. KEYENCE’s VK-X3000 Series 3D Surface Profilers can scan the surfaces of targets with high definition and provide quantitative 3D measurements. The measurement results can be subjected to pass/fail tests by comparing them across multiple samples using 42 roughness parameters. Surface roughness is quantified and roughness distribution can be visualized in graphs, which enables instantaneous quantification of differences in material, finish, texture, feel, and other appearance characteristics.

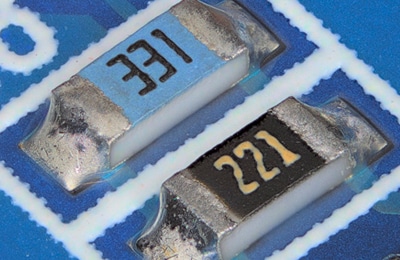

SEM-like imaging

The VK-X3000 is equipped with a color CMOS camera and a 16-bit PMT for capturing the returned laser light. Due to the increased resolution when using a laser over white light, the VK-X is capable of capturing high magnification images with a higher resolution than standard optical microscopes. With a maximum achievable magnification of 28800x, the VK-X can capture high-resolution color images that rival an SEM. Additionally, no sample prep is required when using the VK-X, so images can be captured instantaneously.

Measuring large targets

Generally, 3D surface profilers cannot measure targets that cannot be placed on the XY stage. However, VK-X3000 Series 3D Surface Profilers are structured so that it is possible to separate the microscope into a measuring head and base. This allows for the measurement head to be integrated with larger stages, allowing for a nearly limitless measurement range.

Related Products

Confocal microscopes incorporate a pinhole in front of the light receiving element to block ambient and out-of-focus light. This allows the microscope to use the position that has reflected the most intense light as the true height. The following section describes the individual steps of the detection process of the KEYENCE 3D Laser Scanning Confocal Microscope.

This website provides information on how 3D surface profilers can be used to quantify surface texture and roughness, including relevant terminology, roughness parameter definitions, and the pros and cons of different measuring instruments.

Frequently Asked Questions About 3D Surface Profilers

No, the VK-X3000 Series 3D Surface Profiler can be more easily operated than SEMs and general microscopes. The AI-Scan function automates the data acquisition process, allowing advanced algorithms to handle the adjustment of multiple scan settings. The user is only required to place the target on the stage and press measure. Regardless of the operator's experience or knowledge, the VK-X3000 Series captures accurate, repeatable results, preventing measurement from being restricted to only people with a specific skill set and eliminating hours of training on the system.

The maximum magnification provided by VK-X3000 Series 3D Surface Profiler is 28800× (with a 23-inch monitor full display). We provide a wide-ranging lineup of dedicated lenses from 2.5× to 150×, all of which undergo rigorous inspection before being shipped. Long working distance lenses are available for measuring targets with large height changes and high aspect ratios.

The VK-X3000 Series uses a company license system, allowing for installation and use of the software on multiple computers at no additional cost. The software can also be used remotely, supporting work from home and access from other offices or hotels when travelling. Instant sharing of data among colleagues helps facilitate swift project performance.

The principles and characteristics of laser microscopy are explained, including their advantages over conventional optical microscopes.

This easy-to-understand guide introduces some problems encountered when using SEMs, profilometers, optical microscopes, and laser microscopes, along with examples of how these limitations can be overcome with Keyence's 3D Surface Profiler.

A must-read document for anyone using a scanning electron microscope (SEM). This guide introduces the full extent of the capabilities of the latest 3D surface profilers, using many measurement and observation images. A rich source of information that helps you understand and solve problems you may experience with an SEM.